Spiral electromagnetic sensor-based device for measuring bubble(s) in molten metal

An electromagnetic sensor and measuring device technology, applied in the direction of material magnetic variables, etc., can solve the problems of high cost, low measurement sensitivity, difficult to guarantee the accuracy of measurement, etc., and achieve the effect of good real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

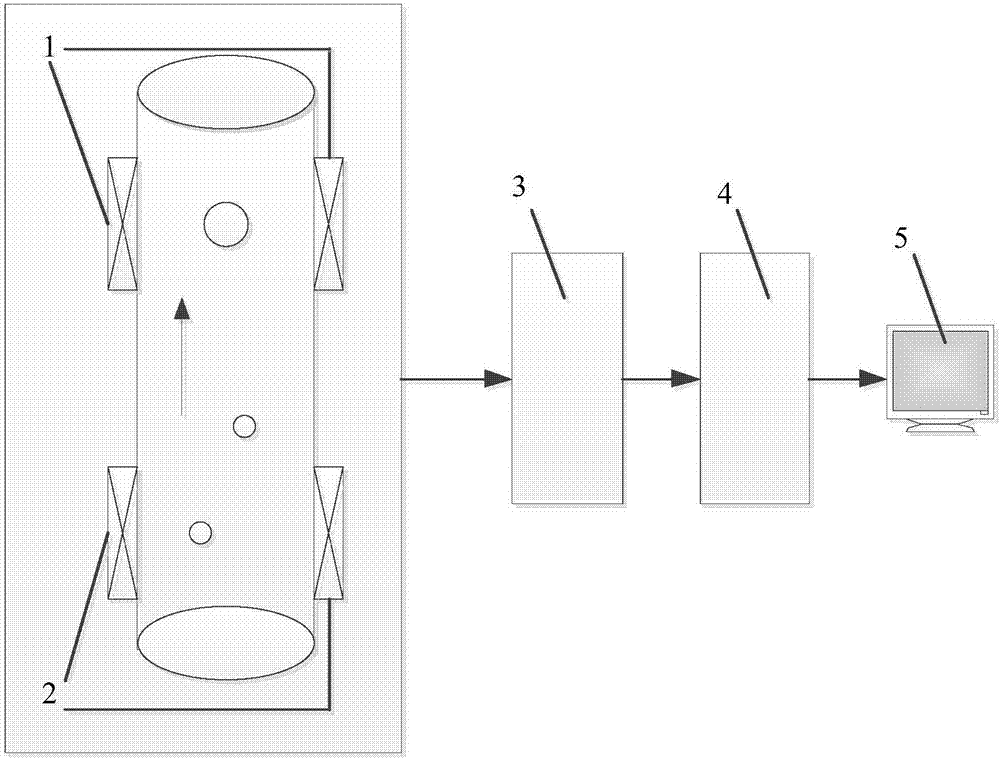

[0013] The structure of the device for measuring air bubbles in molten metal based on the helical electromagnetic sensor of the present invention will be further described in detail in conjunction with the accompanying drawings.

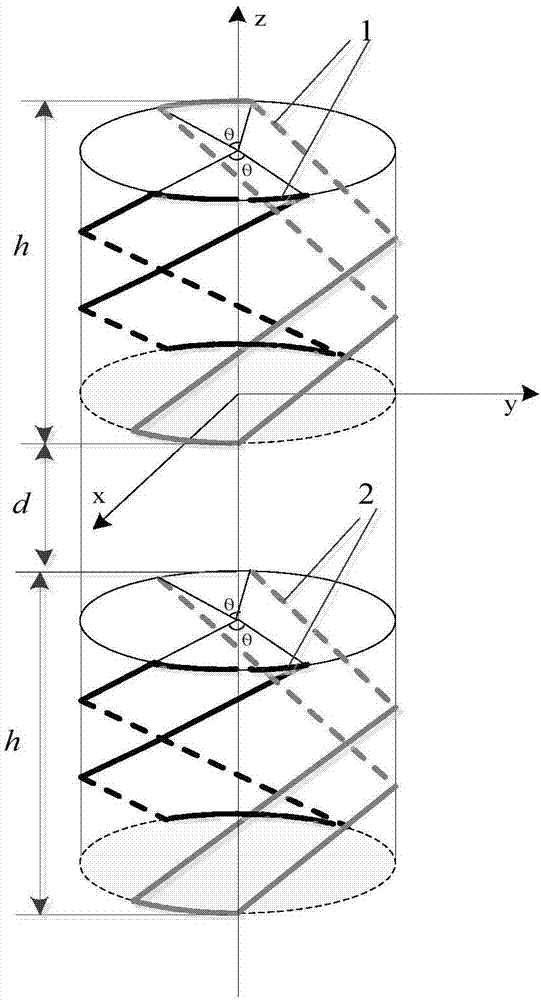

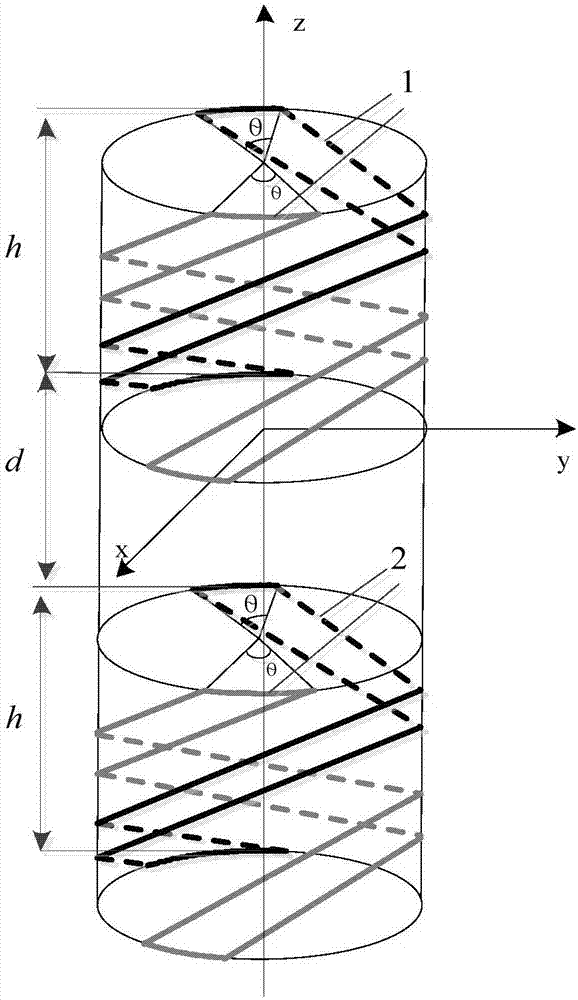

[0014] The design idea of the bubble measuring device in molten metal based on the spiral electromagnetic sensor of the present invention is to adopt a spiral electromagnetic sensor group, which coaxially and parallelly surrounds two different sections on the surface of the measured pipeline in a spiral manner, with a certain axial distance. Keep a certain distance from the measured liquid to achieve non-contact and non-invasive measurement, while providing higher and more uniform sensitivity. Each sensor group includes an excitation coil and a receiving coil. Under certain other conditions, the helical electromagnetic sensor has three adjustable parameters: helix angle α, opening angle θ, and height h. The helix angle can be adjusted according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com