Powder flow pattern detection apparatus in spiral conveyer pipe and compression perception flow pattern identification method

A technology of spiral conveying tube and flow pattern detection, which is applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc. It can solve the problems of large measurement error, poor real-time performance, and limited number of output neurons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The powder flow pattern detection device in the spiral conveying pipe and the compression sensing flow pattern identification method of the present invention will be described below with reference to the accompanying drawings and embodiments.

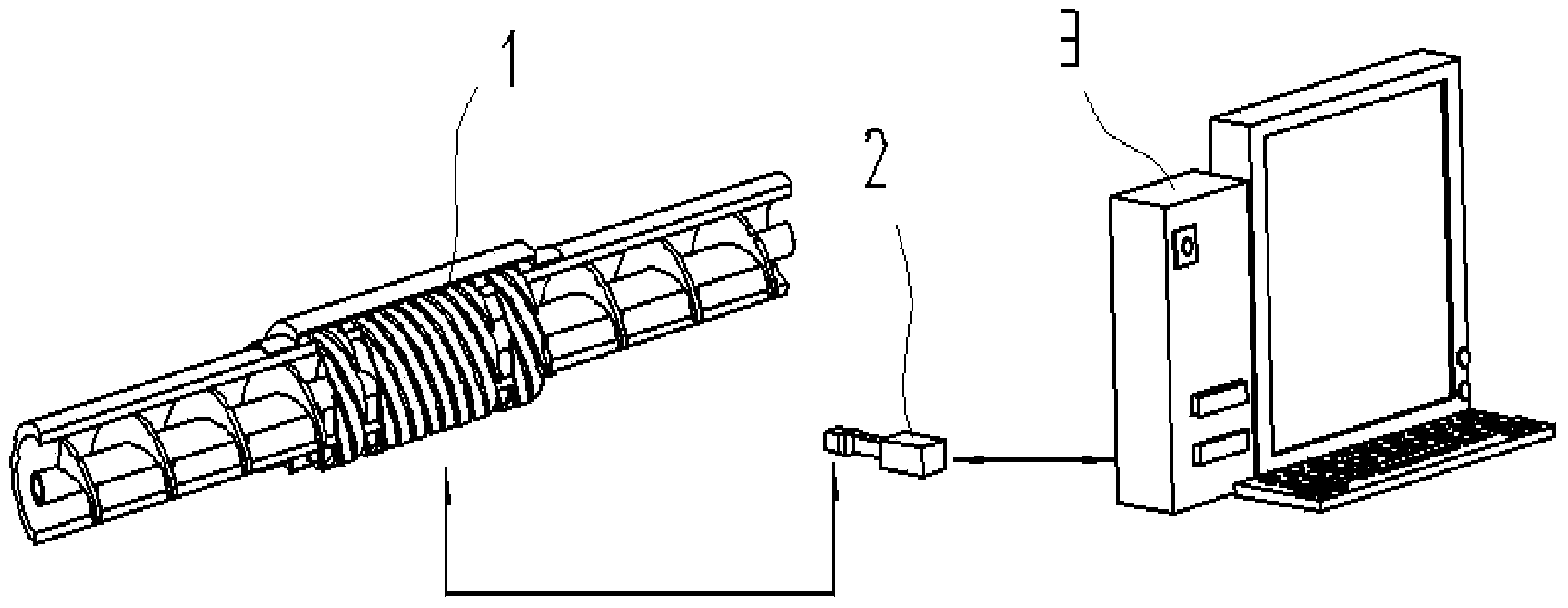

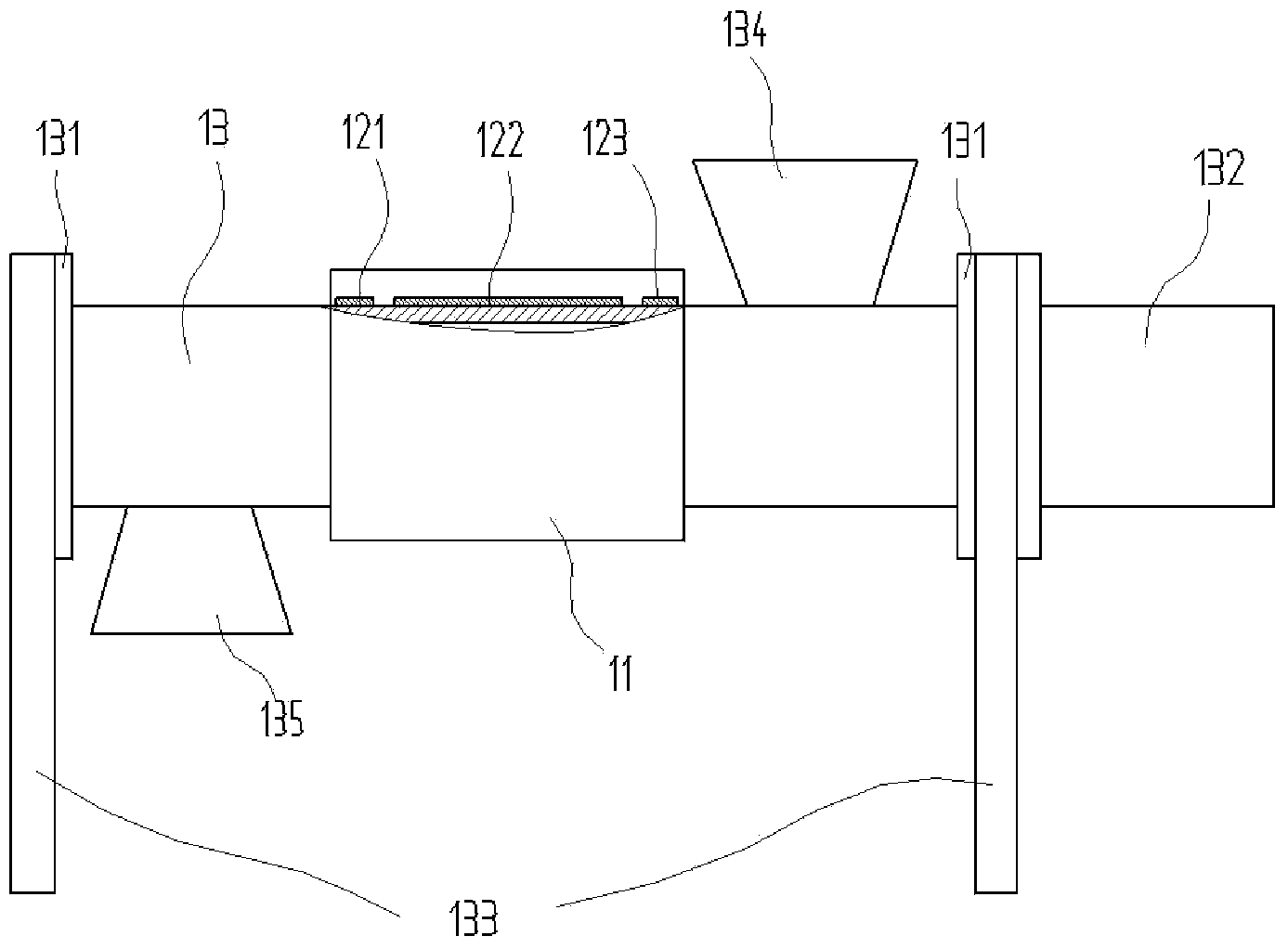

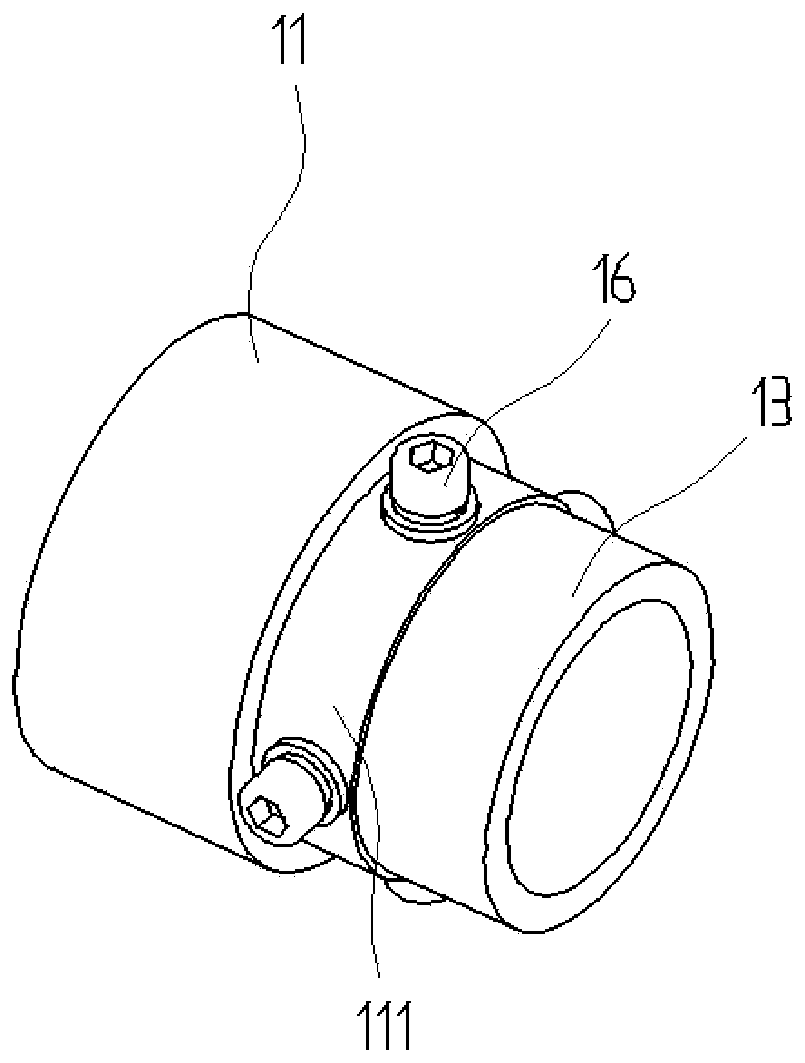

[0069] Such as figure 1 , figure 2 , image 3As shown, the powder flow pattern detection device in the screw conveying pipe of the present invention consists of a horizontal screw conveyor, a front-end shielding electrode array 121, a detection electrode array 122, an end shielding electrode array 123, a shielding cover 11, a signal acquisition and processing unit 2 and The upper computer consists of 3 components.

[0070] The positions and connections of each part are as follows: the horizontal screw conveyor includes a cylindrical insulating pipeline 13, a screw shaft 15 is installed inside the cylindrical insulating pipeline 13, and a screw blade 14 is wrapped around the screw shaft 15. Both ends of the cylindrical insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com