Device and method for measuring flow velocity of metal particles based on triangular electrode capacitive sensor

A capacitive sensor, metal particle technology, applied in measurement devices, fluid velocity measurement, velocity/acceleration/shock measurement, etc., can solve problems such as uneven distribution of sensitive fields, influence of measurement results, etc. Effects of field effects, high measurement accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

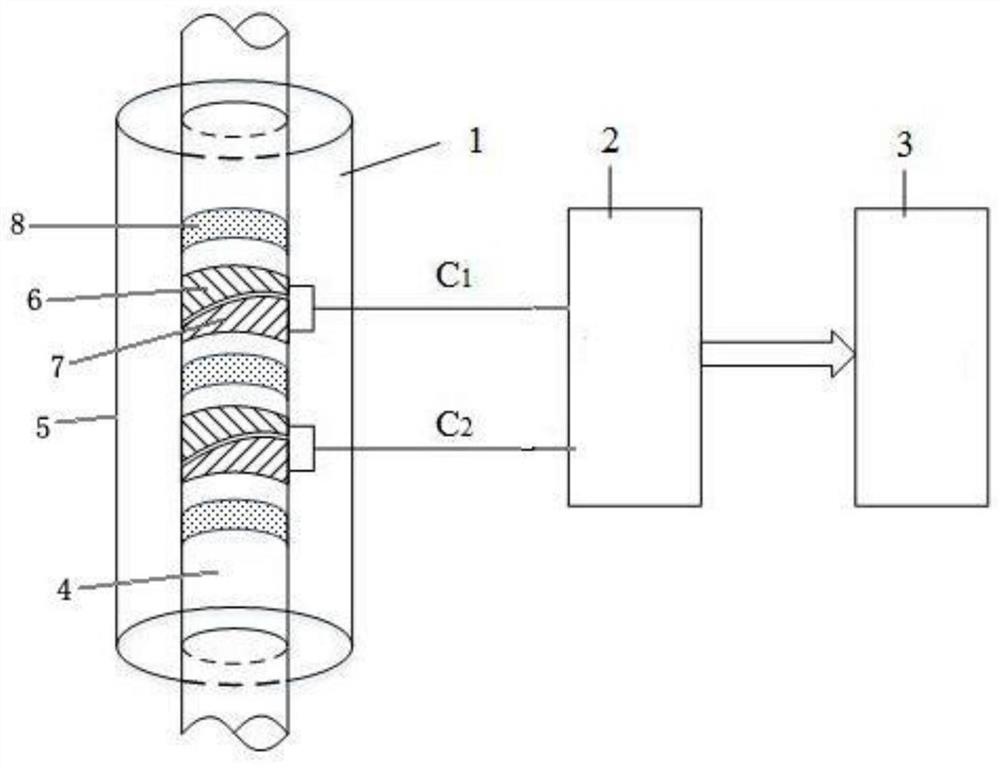

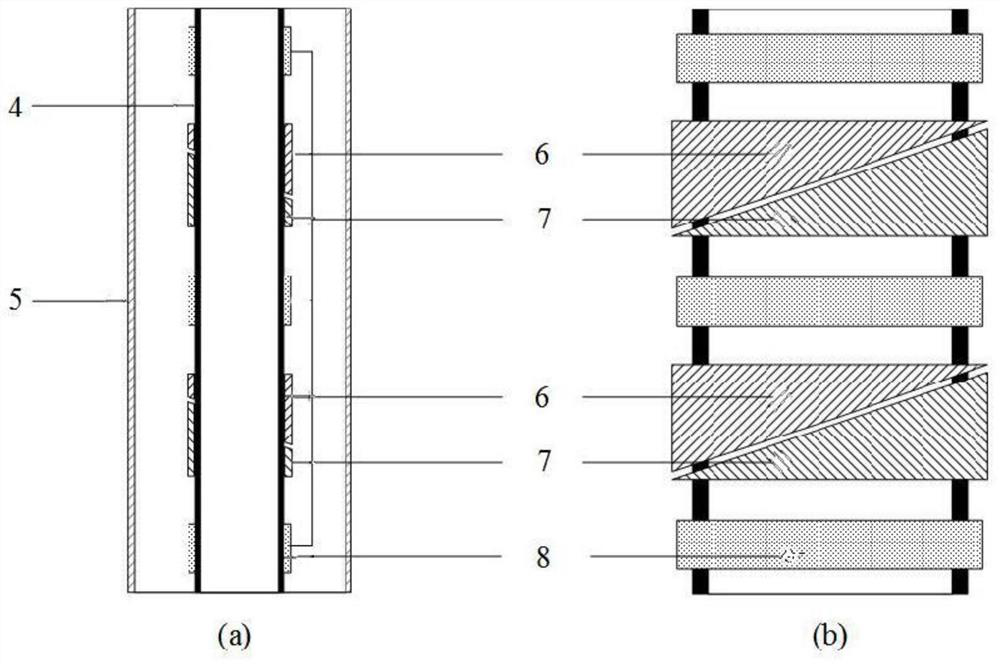

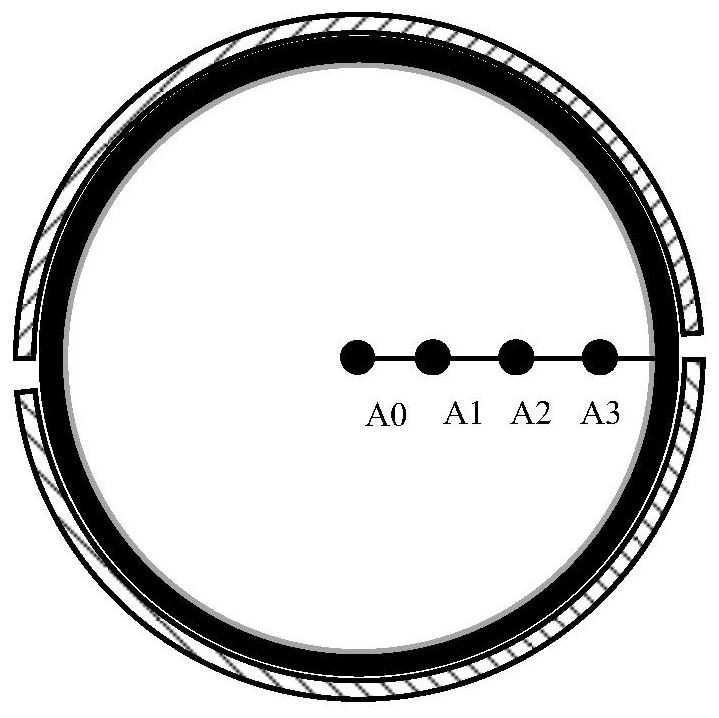

[0057] The present invention is based on the metal particle flow rate measuring device of the triangular electrode capacitive sensor, such as Figure 1-2 As shown, it includes a triangular electrode differential capacitive sensor 1 for detection, a signal acquisition circuit 2 and a computer 3 that are electrically connected in sequence, wherein the triangular electrode differential capacitive sensor 1 includes an insulating pipeline 4, and the insulating pipeline 4 is surrounded by a certain distance. Two groups of upstream electrode pairs C with the same size and structure arranged axially along the insulation pipe 4 1 and downstream electrode pair C 2 , above the upstream electrode pair, between the upstream electrode pair and the downstream electrode pair, and below the downstream electrode pair, there are ring-shaped shielding electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com