Ultra-thin thermal shrinkage belt fastening optical cable structure and production method

A heat-shrinkable tape and ultra-thin technology, which is applied in the direction of fiber mechanical structure, light guide, optics, etc., can solve the problems that affect the performance and service life of the optical cable, strangle marks, and damage to the loose tube in the optical cable, so as to improve the temperature performance and mechanical Performance, increased friction, cost-reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings.

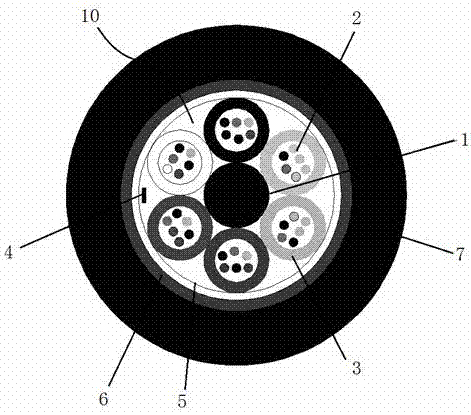

[0017] Such as figure 1 As shown, an ultra-thin heat-shrinkable tape fastening optical cable structure of the present invention includes a central strength member 1, an optical fiber 2, a loose tube 3, an ultra-thin heat-shrinkable tape 5, an armor layer 6 and a PE sheath 7. The piece 1 and several loose tubes 3 are twisted and combined to form a cable core 10. The optical fiber 2 is passed through the loose tube 3, the PE sheath 7 is wrapped on the outer surface of the cable core 10, the ultra-thin heat shrinkable tape 5 and the armor layer 6 The cable core 10 is sequentially wrapped from the inside to the outside.

[0018] The ultra-thin heat-shrinkable tape 5 in the present invention is made of PET heat-shrinkable film material; the armor layer 6 is wound by steel or aluminum tape. The armor layer 6 is used to increase the strength of the optical cable.

[0019] A tear cord 4 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com