Automatic batch skewering machine

A stringer and batch technology, which is applied in the direction of skewering meat onto meat skewers, meat processing equipment, slaughtering, etc., can solve the problems of high labor cost and time cost, difficulty in ensuring the hygiene and safety of skewered products, and low processing efficiency. , to achieve the effect of improving processing efficiency, saving time and labor costs, and saving processing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

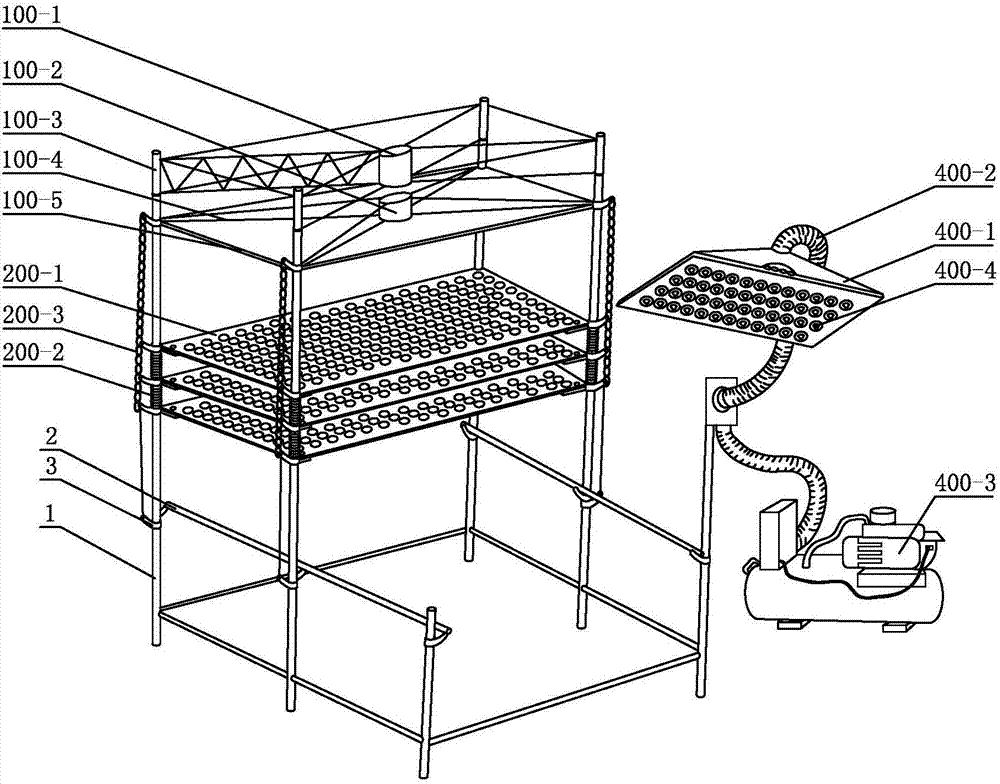

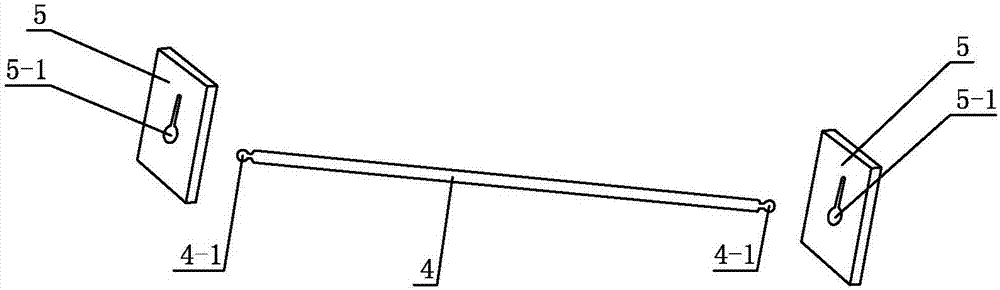

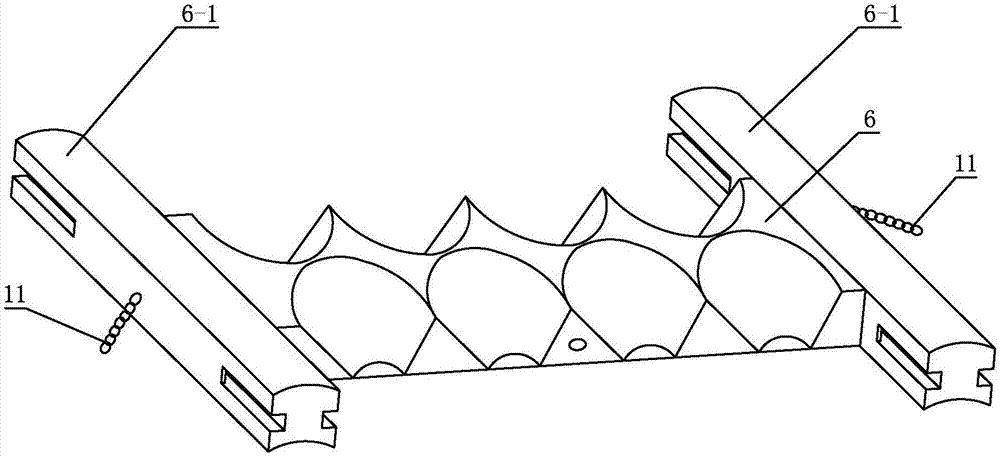

[0025] Specific implementation mode one: combine figure 1 , figure 2 , Figure 14 and Figure 15 Describe this embodiment, an automatic batch threading machine of this embodiment, which includes a bracket 1, a hydraulic cylinder, a sign pushing device, a sign limiting device, a material suction device, two template slides 2, a plurality of curved arms 3 and Multiple sets of material setting templates, sign pushing device, sign limiting device and multiple sets of material setting templates are arranged on the support 1 in sequence from top to bottom, the suction device is installed on the side column of the support 1, and the sign pushing device includes the upper chamber of the oil cylinder 100 -1, oil cylinder lower chamber 100-2, upper chamber support 100-3, lower chamber support 100-4 and sign pushing plate 100-5, the four bushings of the upper chamber support 100-3 are set on the four vertical supports of the support 1 The upper end of the rod is fixedly connected to ...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 and Figure 16 Describe this embodiment, the suction device of this embodiment includes negative pressure suction pan 400-1, negative pressure suction universal arm 400-2 and negative pressure vacuum suction pump 400-3, negative pressure suction pan 400- The lower end surface of 1 is provided with a plurality of suction holes 400-4 in a rectangular array, the negative pressure suction universal arm 400-2 is a hollow tubular universal arm, and one end of the negative pressure suction universal arm 400-2 is connected to the The upper end of the negative pressure suction tray 400-1 is connected, and the other end of the negative pressure suction universal arm 400-2 is connected with the negative pressure vacuum suction pump 400-3. With such a setting, using the suction device instead of the traditional manual placement of string products into the material placement template, on the one hand, the processing efficiency ...

specific Embodiment approach 3

[0029] Specific implementation mode three: combination Figure 8 Describe this embodiment, this embodiment also includes a first sign setting device, the first sign setting device includes a sign setting plate 500-1, a first handle 500-2, a first inner handle 500-3, a connecting rod 500-4, a spring and a plurality of clamping rods 500-5, the first handle 500-2 is installed on one end of the signing board 500-1, and the connecting rod 500-4 is inserted in the signing board 500 along the longitudinal axis N-N direction of the signing board 500-1 -1, one end of the connecting rod 500-4 is affixed to the spring, the other end of the spring is affixed to the sign setting plate 500-1, the first inner handle 500-3 is installed on the other end of the connecting rod 500-4, and the sign setting plate The upper end surface of 500-1 is evenly provided with a plurality of lottery slots 500-6, and the plurality of lottery slots 500-6 are all perpendicular to the longitudinal axis N-N of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com