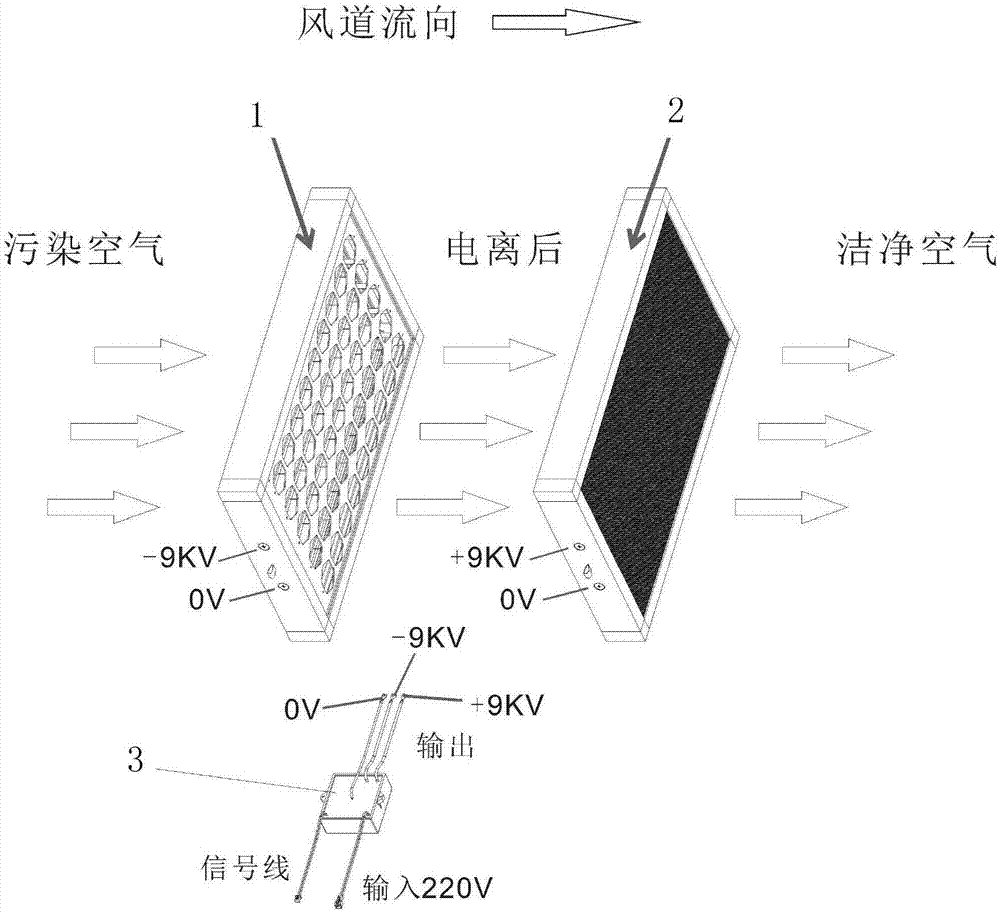

Micro-electrostatic purification device

A purification device, micro-electrostatic technology, applied in electrostatic separation, external electrostatic separator, power supply technology, etc., can solve the problems of circuit resistance, variation, powder drop of toner conductive belt, etc., to achieve easy powder drop, ensure integrity and Reliability, the effect of increasing functional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

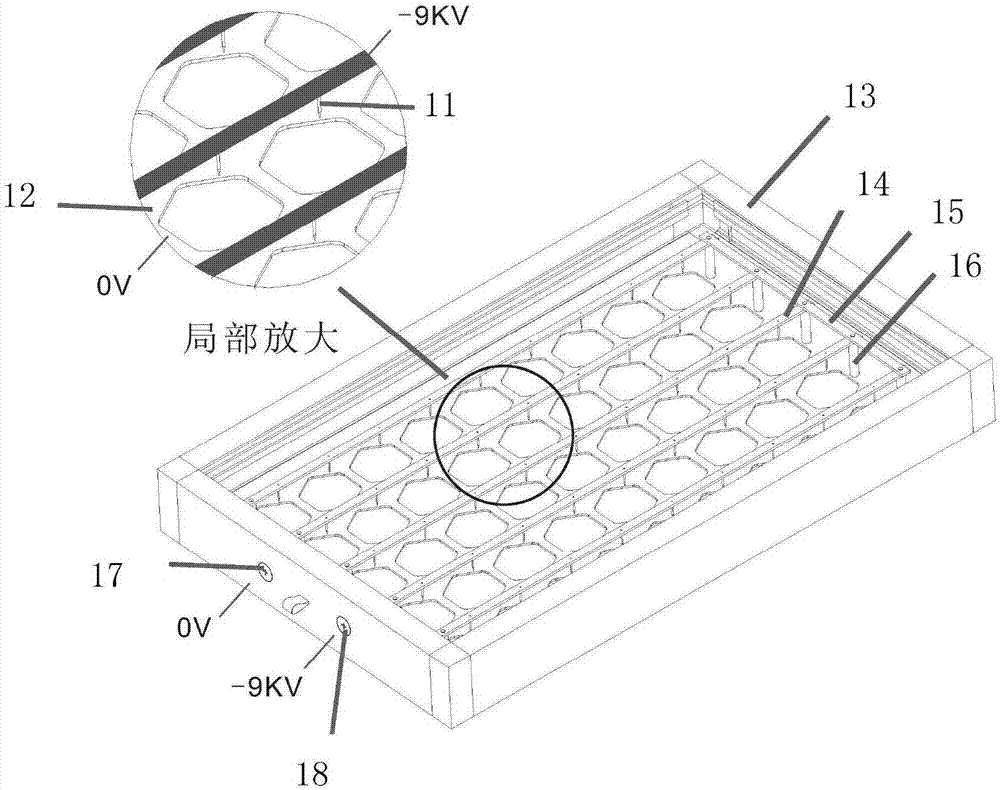

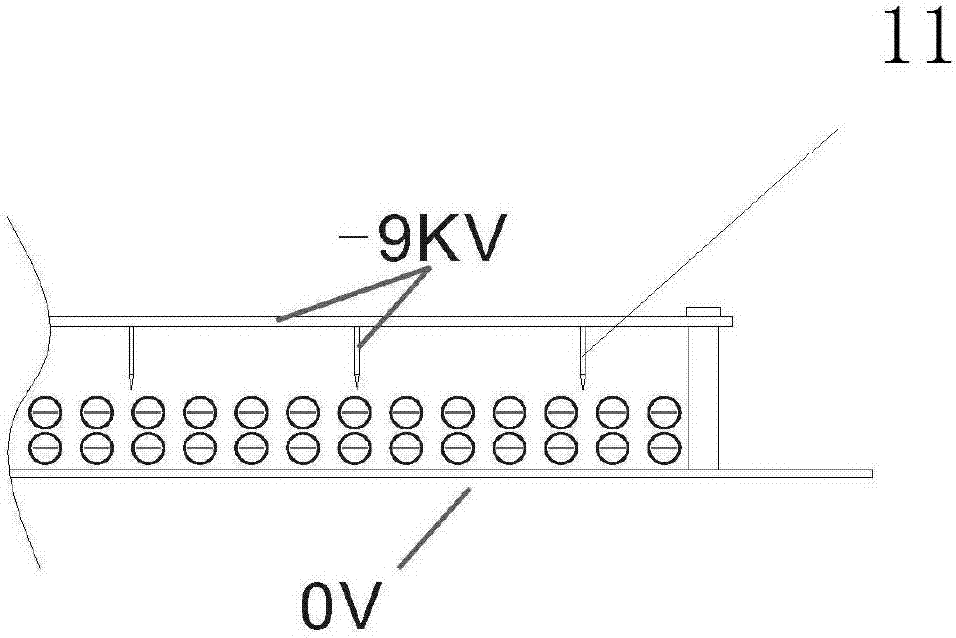

[0022] Such as Figure 1 to Figure 8 As shown, a micro-static purification device includes a high-voltage power supply module 3, an ionization module 1 and a dust collection module 2 connected to the ionization module 1, and the high-voltage power supply module 3 is connected to the ionization module 1 and the dust collection module respectively. 2 are electrically connected, the dust collection module 2 includes a first copper strip 24, a second copper strip 22 and an electret fiber board 21, the first copper strip 224 is connected with a first bifurcated copper strip 25, and the second copper strip 22 The band 22 is connected with a second forked copper strip 23, the first forked copper strip 25 and the second forked copper strip 23 are alternately arranged, and the electret fiber board 21 is arranged on the first forked copper strip 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com