Adjustable glue pouring control mechanism

A control mechanism and glue filling technology, which is applied to the surface coating liquid device, coating, etc., can solve the problem of inability to realize the miniaturization of the glue filling control mechanism, poor glue filling control accuracy, and unadjustable glue filling speed, etc. problem, to achieve the effect of reducing volume and weight, adjustable deglue speed, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

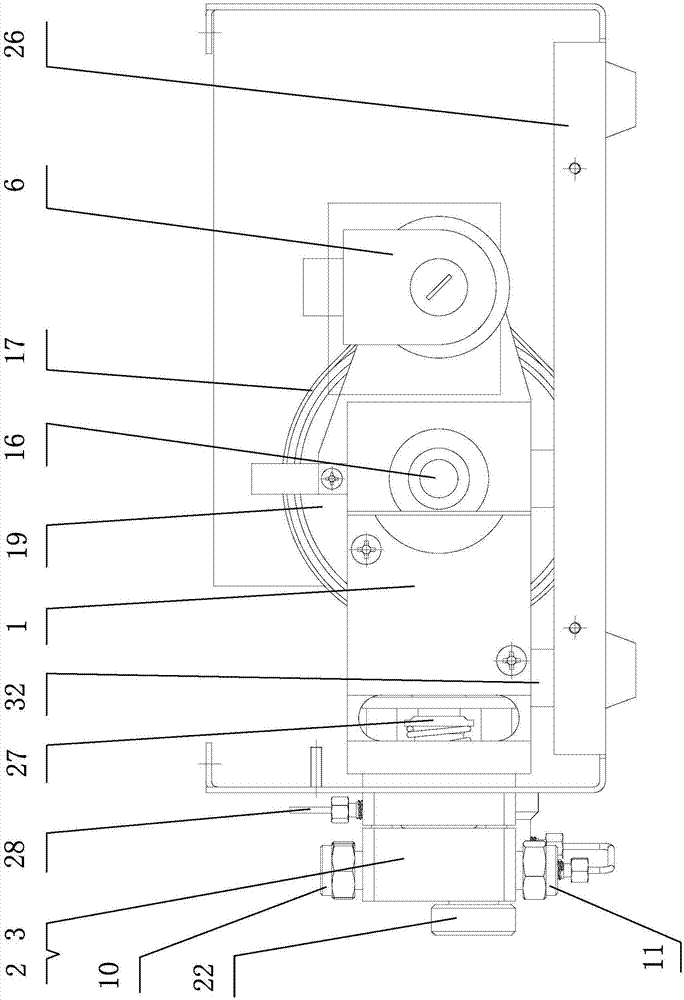

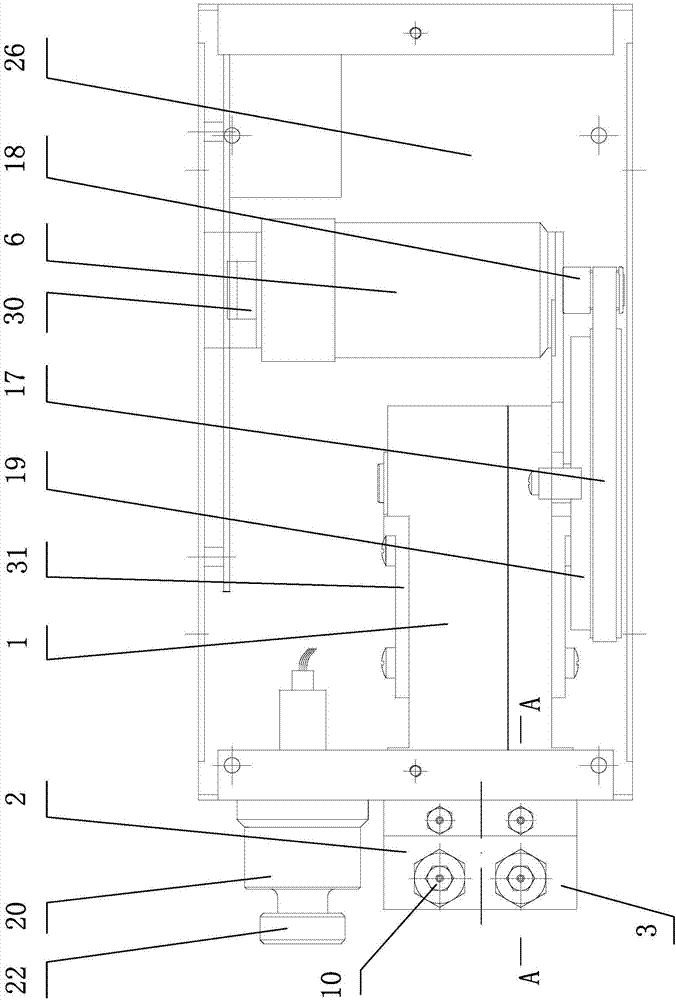

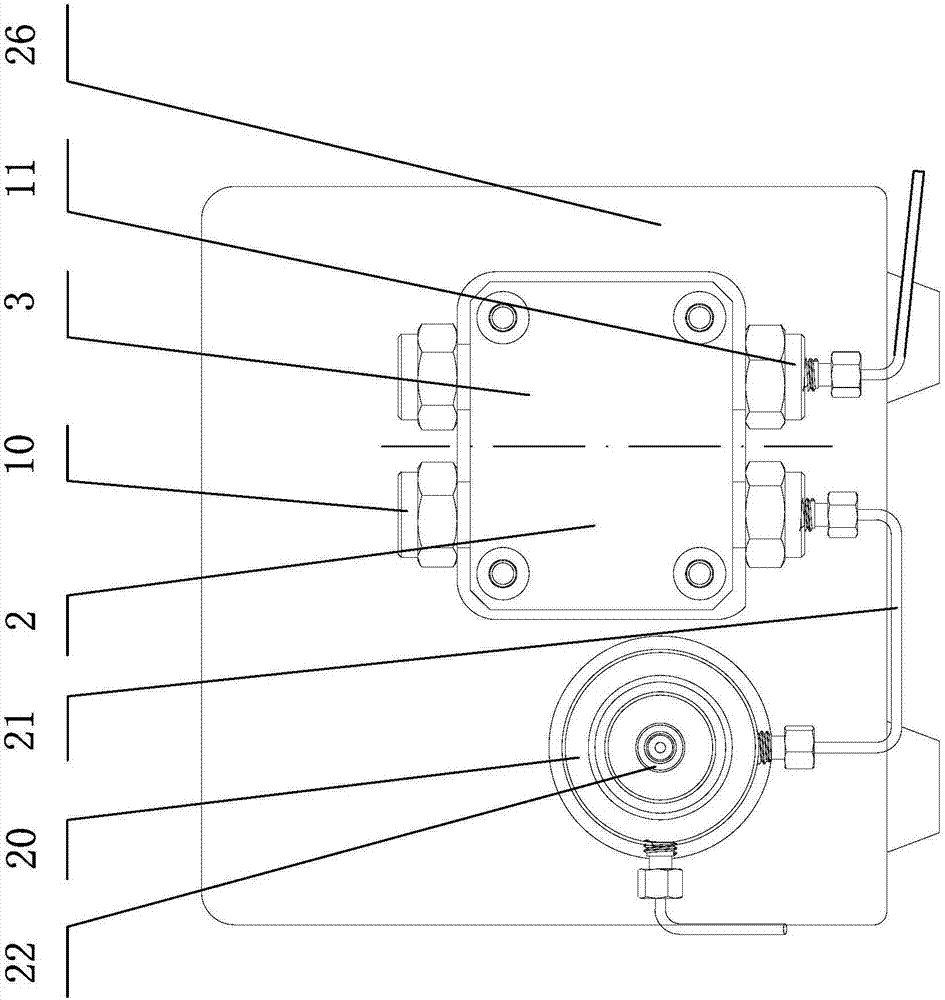

[0028] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0029] The adjustable glue filling control mechanism of the present invention, its technical scheme includes the pump body 1 installed in the pump box 26, the front end of the pump body 1 is equipped with a pump head, and the pump box 26 at the rear end of the pump body 1 is installed with an encoder 30 DC servo motor 6, the DC servo motor 6 drives the pump head on the pump body 1 to work through the synchronous pulley transmission mechanism, the pump head adopts a double-plunger parallel reciprocating pump head structure, and the pump box 26 A baffle plate 31 is provided to limit the left and right sides of the pump body 1, and the bottom of the cabinet 26 is provided with a shock absorber 32 placed below the pump body 1, such as figure 1 , figure 2 , image 3 shown.

[0030] The pump heads are the first and seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com