Pressing type container

A press-type, container technology, applied in the field of daily necessities, can solve problems such as poor user experience and inability to solve the problem of residual amount, and achieve the effect of reducing residual amount, reducing direct contact and improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

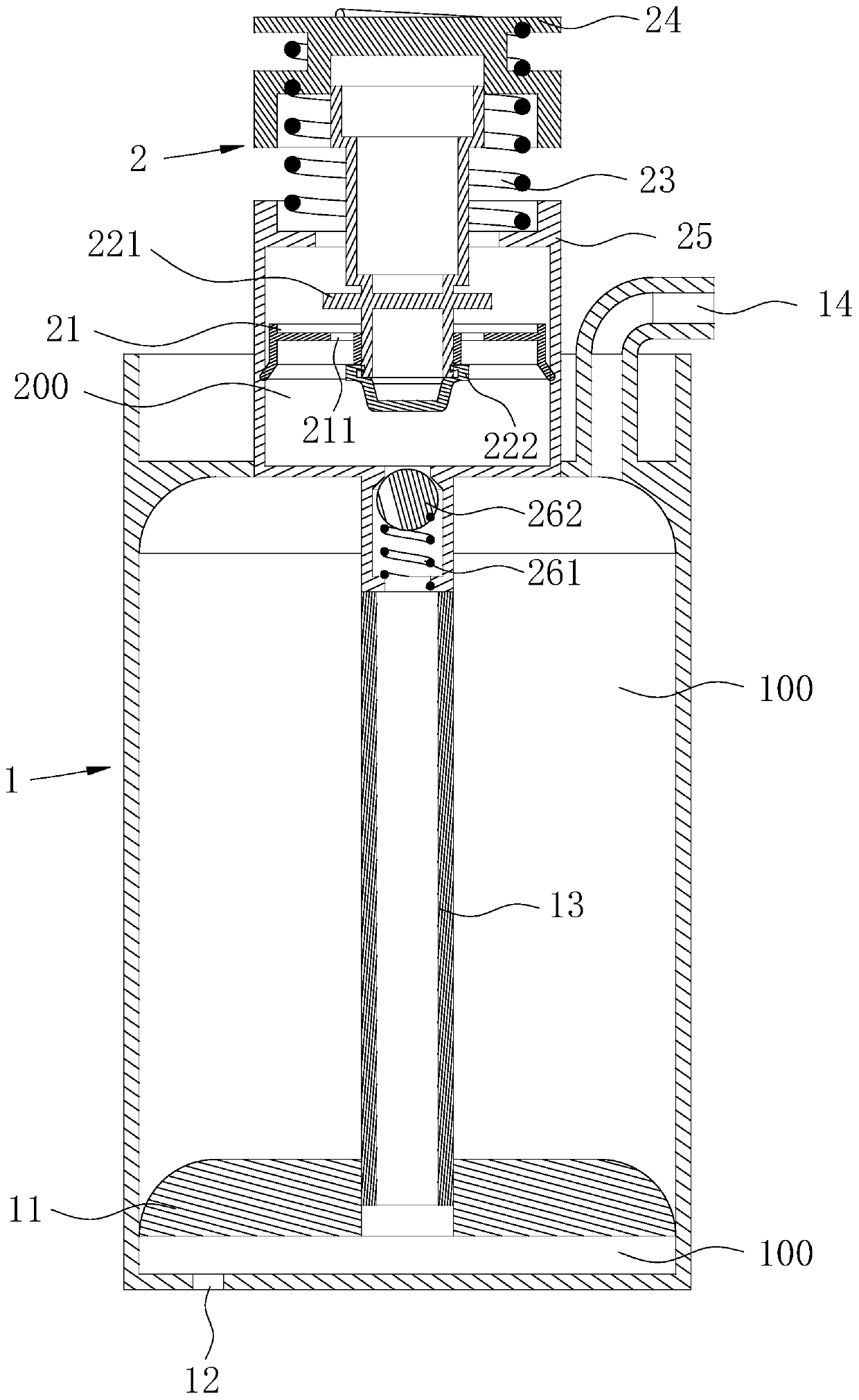

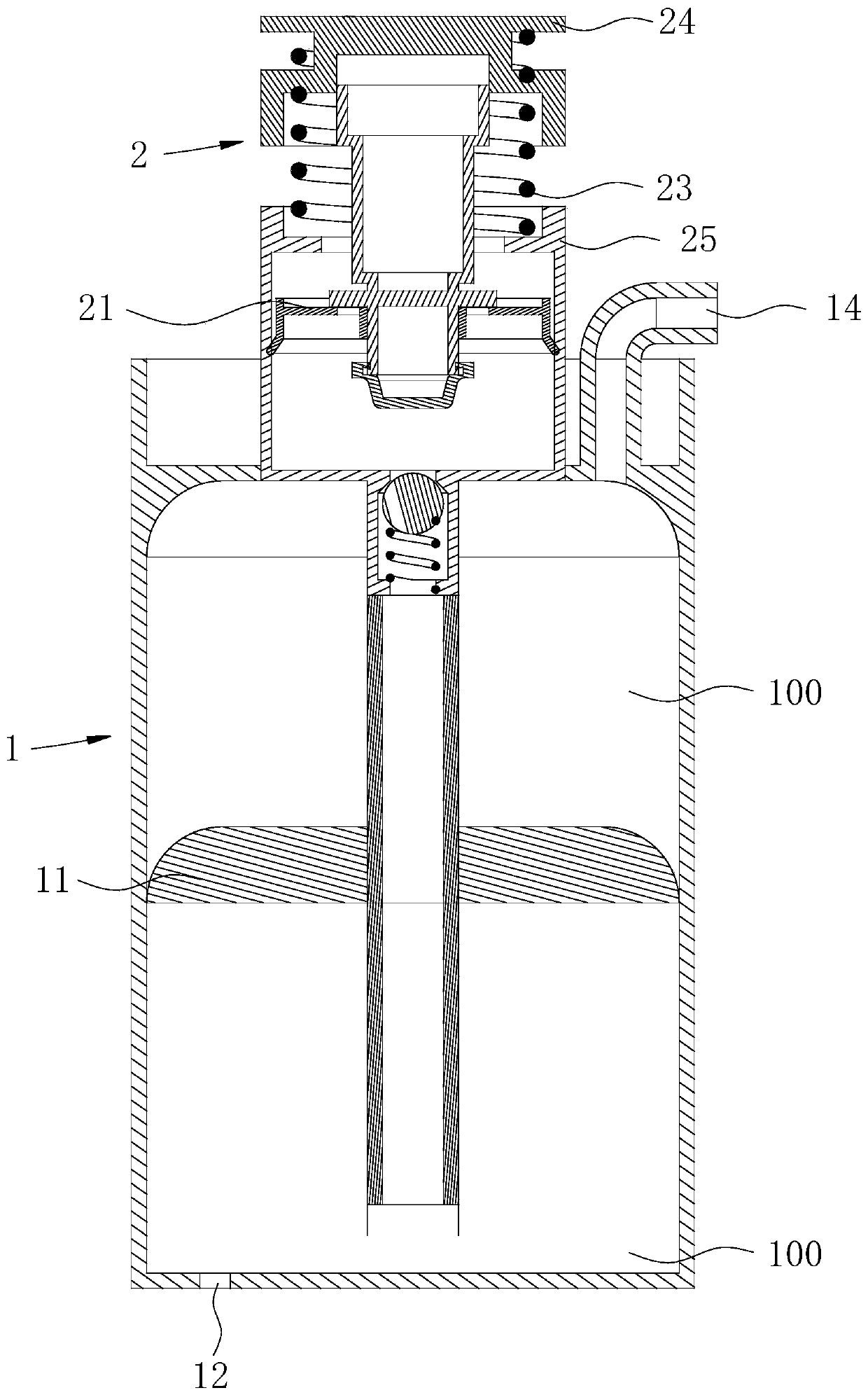

[0039] Such as Figure 1 to Figure 8 As shown, the push-type container of this embodiment includes a container body 1 and an air pump assembly 2. There is a first chamber 100 inside the container body 1, and a liquid discharge piston 11 is arranged inside the first chamber 100, and the center of the liquid discharge piston 11 is provided with a The through hole allows it to be sleeved on the outer wall of the air pipe 13 and move up and down along the air pipe 13 to squeeze the liquid in the container body 1 and discharge the liquid from the liquid outlet 14 communicating with the first chamber 100 .

[0040] The air pump assembly 2 is connected to the container body 1 and includes an air pump piston 21 , a pump core 22 , an air pump spring 23 , a pump head 24 , a pump body 25 and a one-way air valve 26 . There is a second chamber 200 in the pump body 25, and the pump body 25 is provided with an opening 251 for the pump core 22 to move up and down. There is always a gap in be...

Embodiment 2

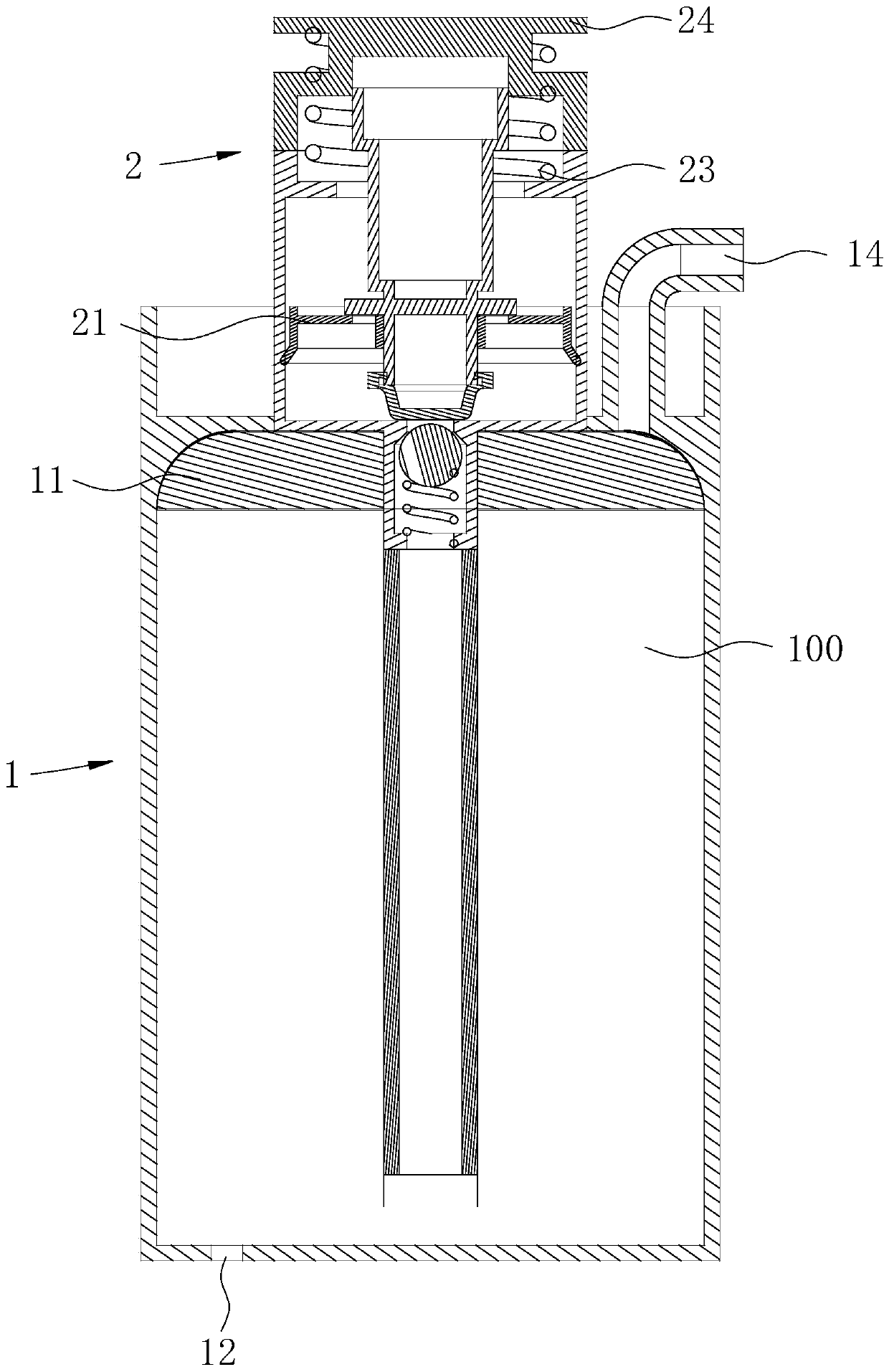

[0052] Such as Figure 10 As shown, the air pump assembly 2 of the push-type container in this embodiment is located on one side of the container body 1 instead of the middle, and correspondingly, the air tube 13 is located outside the container body 1 instead of inside. In this embodiment, the gas pipe 13 is arranged outside the container body 1, which further reduces the direct contact between the liquid and the structural parts, reduces the liquid residue, and reduces the risk of liquid and air leakage of the liquid discharge piston 11.

Embodiment 3

[0054] In this embodiment, the movement direction of the liquid discharge piston 11 in the second embodiment is changed from the vertical direction to the horizontal direction, and the shape of the inner wall of the first chamber 100 is adjusted accordingly to match the shape of the liquid discharge piston 11 . By changing the direction of movement of the liquid discharge piston 11 from the vertical direction to the horizontal direction, a container body 1 with a lower height can be used, and a larger capacity can be obtained by increasing the size in the horizontal direction, so as to adapt to some applications with limited height and space Scenes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com