Steelmaking continuous casting robot cutting system

A cutting system, steelmaking and continuous casting technology, applied in the field of steelmaking and continuous casting robot cutting system, can solve the problems of affecting cutting quality, increasing energy consumption, and short service life of cutting devices, so as to improve the cutting environment and avoid the problem of slag hanging , Improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

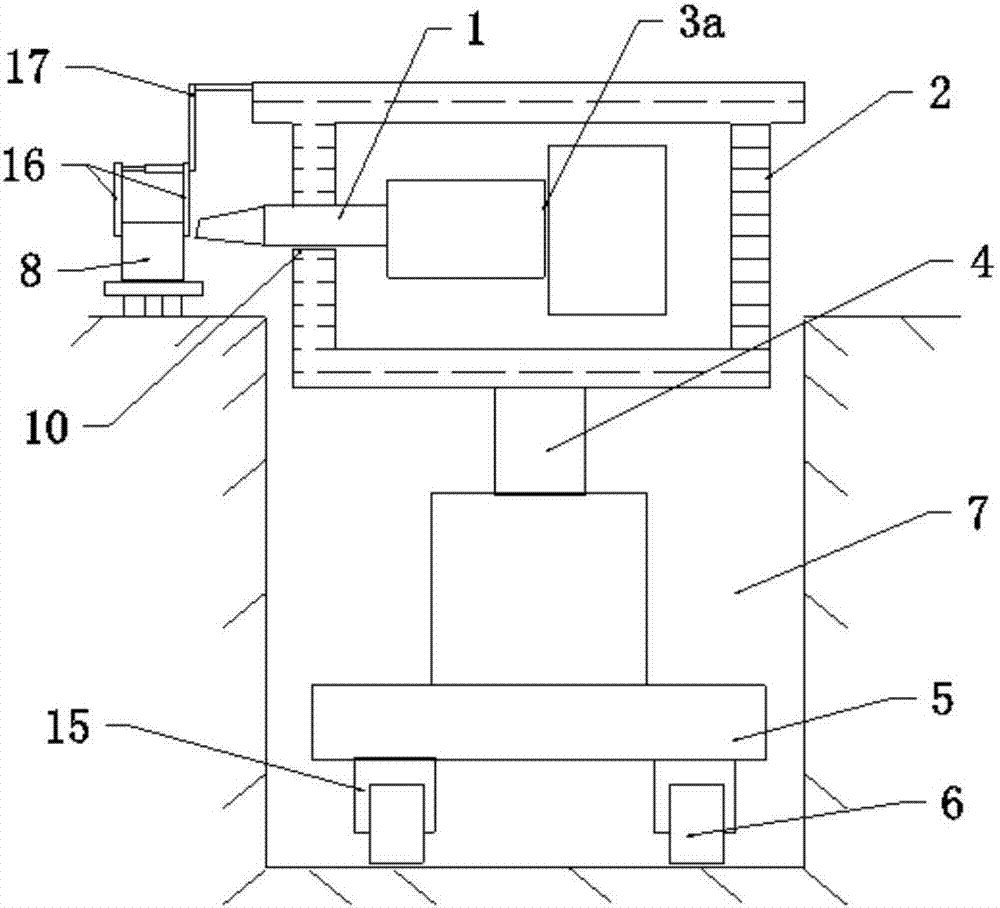

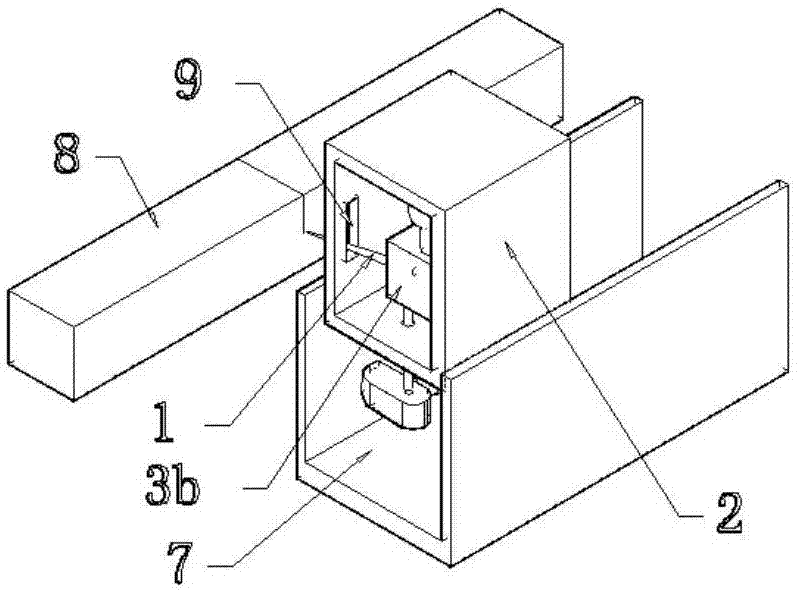

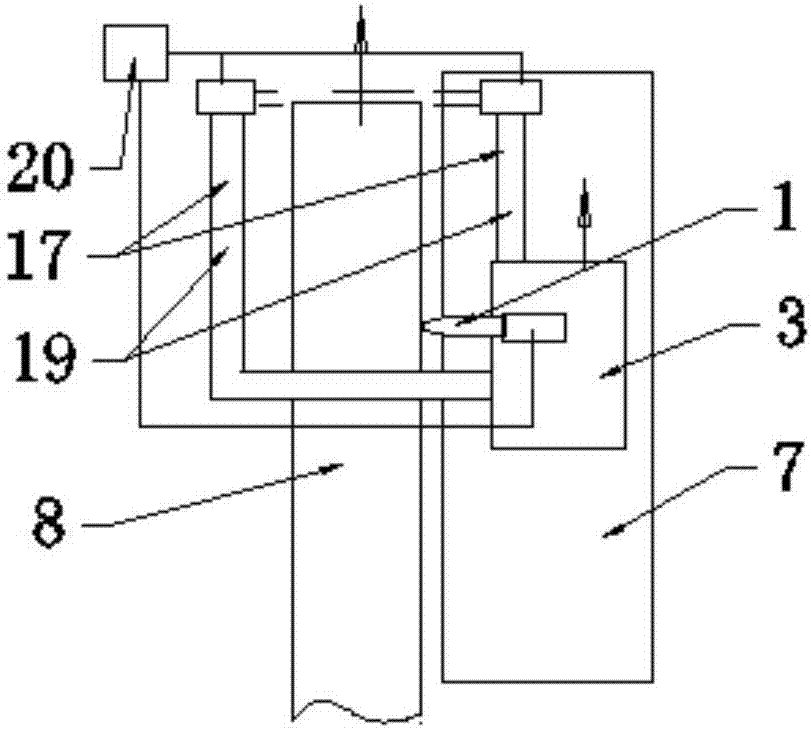

[0014] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings. Such as figure 1 shown. The steelmaking and continuous casting robot cutting system of this embodiment includes trenches or ground passages 7 arranged on the corresponding side of the continuous casting billet along the output direction or length direction of the cut body (continuous casting billet) 8, the cutting robot and the Cutting robots and cutters for continuous casting billets, corresponding control systems, etc. The cutter includes a cutting gun, or includes a cutting gun and a corresponding ignition gun.

[0015] In the present invention, the cutting robot is placed on the corresponding side of the continuous casting billet, and the cutting tool can be extended to the upper, lower, left or right side wall of the continuous casting billet, that is, it can cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com