Mobile production line for producing non-excavation flexible pipeline

A mobile production line and flexible pipeline technology, applied in applications, household appliances, tubular objects, etc., can solve the problems of large pipeline length, pipeline wear, pipeline deformation and damage, etc., and achieve the effect of large operating space, real-time control, and real-time production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

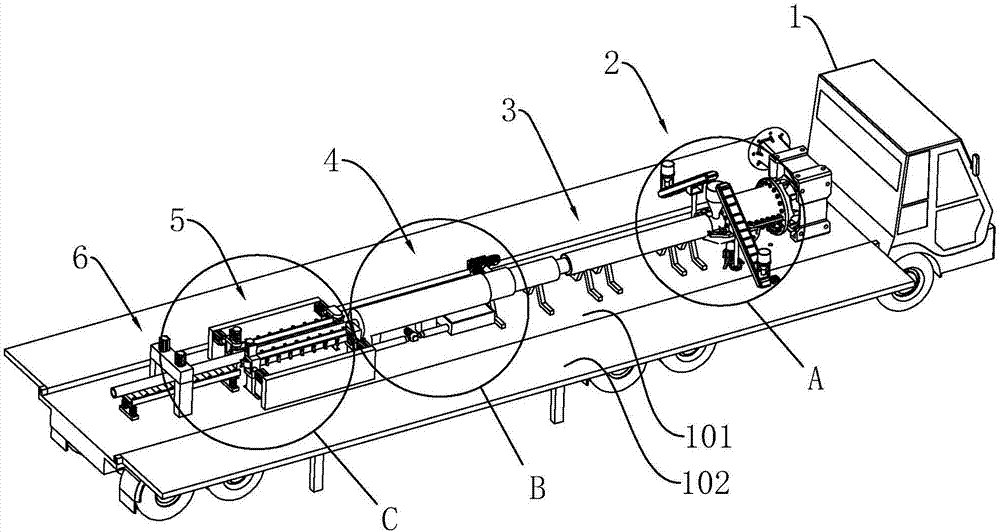

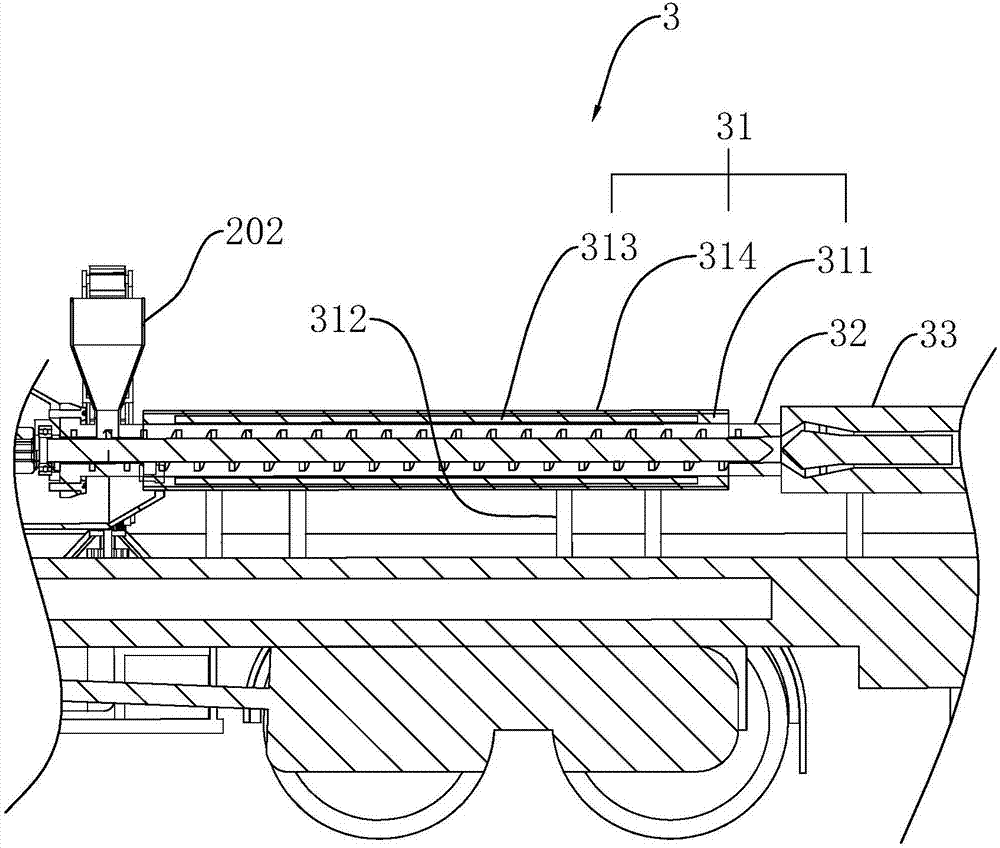

[0048] Example: Reference figure 1 , a mobile production line for producing non-excavation flexible pipelines, including a transport vehicle 1, and the transport vehicle 1 includes a transfer plate 101. The transfer plate 101 is sequentially connected with a feeding device 2, an extruding device 3, a shaping device 4, a pulling device 5 and a cutting device 6, so as to realize feeding, extrusion, shaping, pulling and cutting of the pipe.

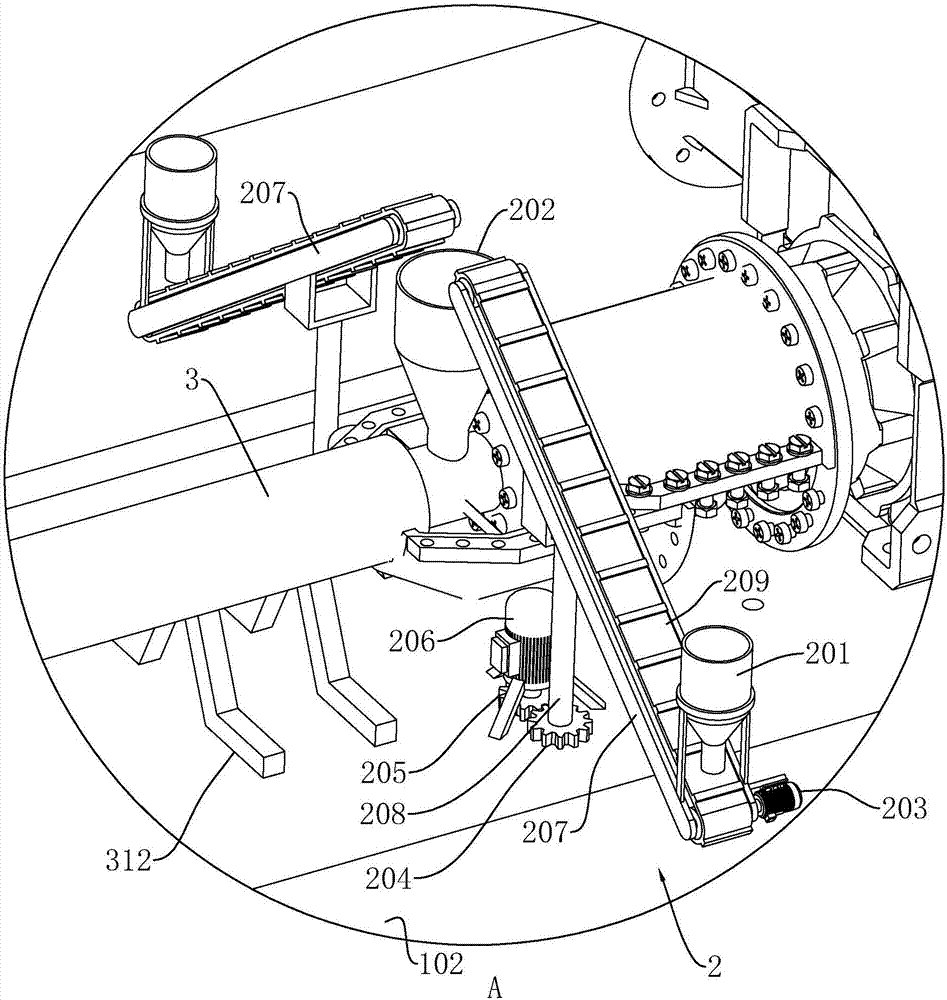

[0049] refer to figure 2 , the feeding device 2 comprises a passive transfer tray 204, a transfer rack 208 connected to the passive transfer tray 204, the transfer rack 208 is connected with a feeding plate 207, and a feeding belt 209 is wound on the feeding plate 207, The feeding belt 209 accommodates raw materials through several grids. The bottom end of the feeding board 207 is extended upwards to provide a raw material funnel 201 . One side of the feeding board 207 is provided with a conveying motor 203 . Driven by the driving action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com