Transporting device preventing workpieces from being damaged during transporting

A technology for transporting devices and workpieces, applied in the directions of transportation and packaging, furnace components, conveyor objects, etc., can solve the problems of lack of shock absorption, affecting the quality of glass, easy sliding of glass, etc., to achieve stable fixation, convenient and fast operation, Anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

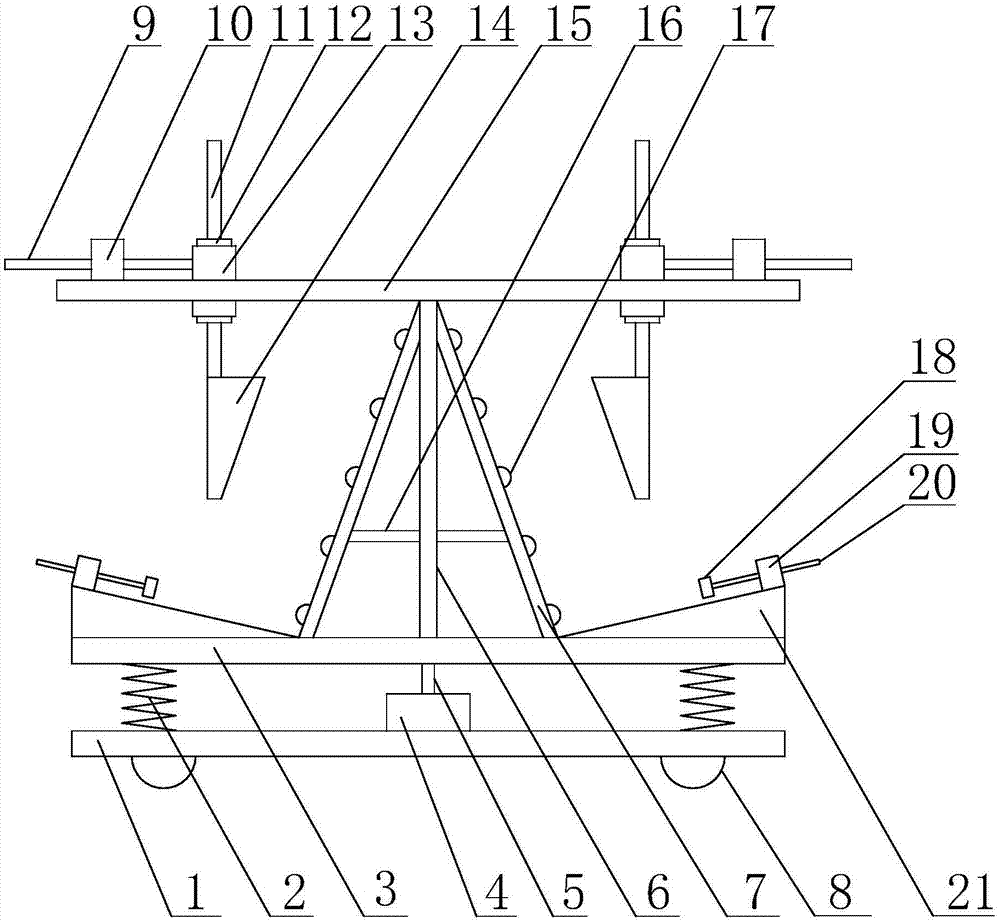

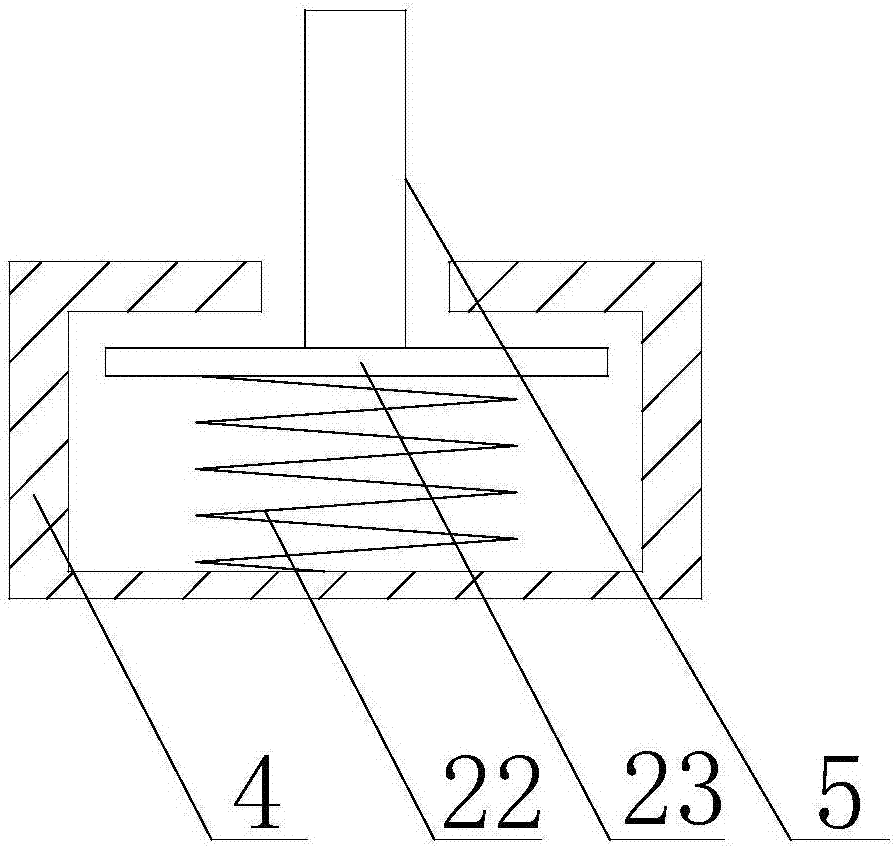

[0027] like figure 1 , figure 2 As shown, the transportation device for preventing workpieces from being damaged during transportation in the present invention includes a base 1 and several universal wheels 8 arranged on the bottom of the base 1, the top of the base 1 is provided with a limit block 4, and the limit The block 4 is located at the central position of the base 1, and the inside of the limiting block 4 is provided with a cavity, and the second buffer element 22 is arranged in the cavity, and the second buffer element 22 is a spring, which has a good buffer function. One end of the buffer element 22 is connected to the inner bottom of the cavity, and the other end is provided with a limiting plate 23, which is located in the cavity of the limiting block 4, and the limiting plate 23 can move vertically in the cavity , the limiting block 4 limits the limiting plate 23 in the cavity of the limiting block 4, the top of the limiting plate 23 is provided with a connecti...

Embodiment 2

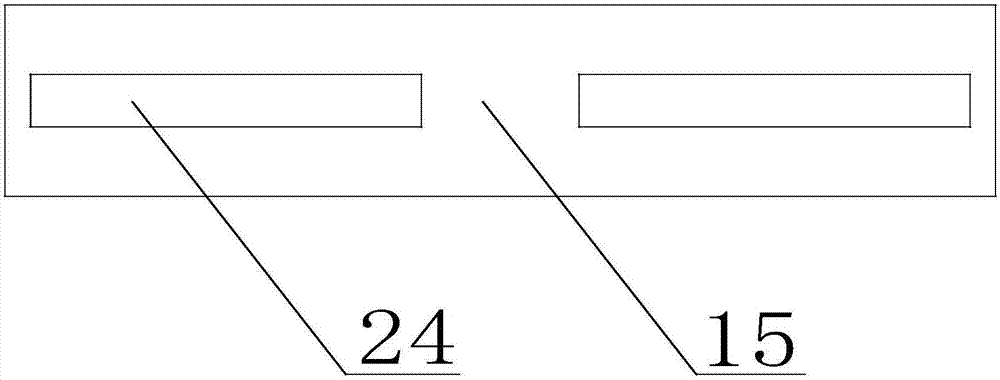

[0029] like figure 1 , image 3As mentioned above, the transportation device of the present invention to prevent workpieces from being damaged during transportation, on the basis of Embodiment 1, an inclined platform 21 is also provided on the top of the support platform 3, and there are two inclined platforms 21, which are respectively located on the support platform 3 On both sides of the axis of the inclined platform 21, the angle formed by the inclined surface of the inclined platform 21 and the horizontal plane is 30°. The inclined surface of the inclined platform 21 is used to place glass. Adjusting rod 20, the adjusting rod 20 is connected with the fixed block 19 by threads, the end of the adjusting rod 20 towards the baffle plate 7 is provided with a second clamping block 18, the rotating adjusting rod 20, the adjusting rod 20 can push the second clamping block 18 moves along the slope of the inclined platform 21, and clamps the glass placed obliquely on the inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com