Automatic impurity-discharging and feeding machine

A feeder, automatic technology, used in conveyors, rotary conveyors, loading/unloading, etc., can solve the problems of increased resistance of the drive motor, the impeller does not rotate, and the drive motor heats up, and achieves reduced deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

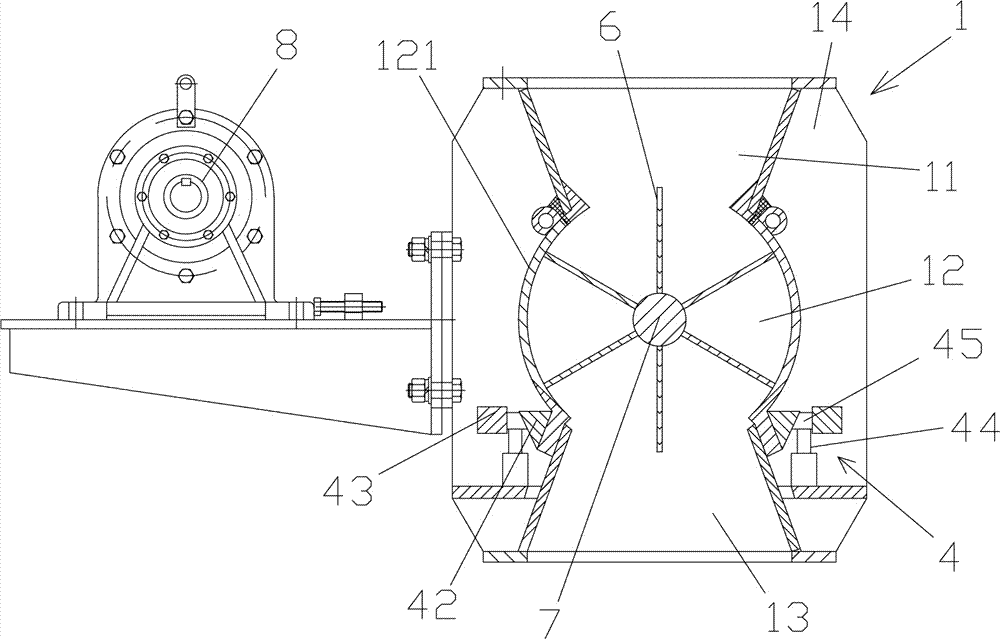

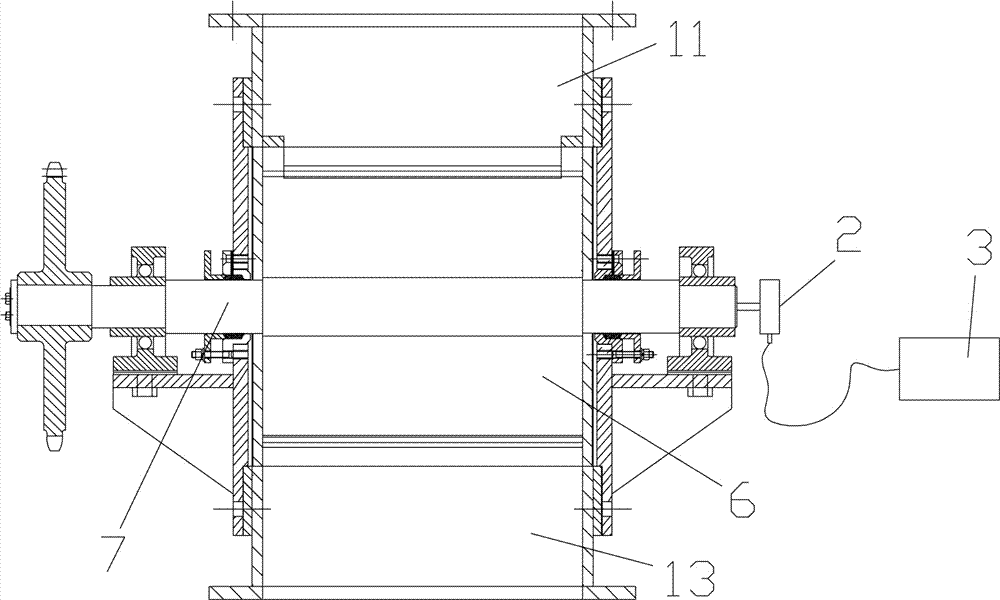

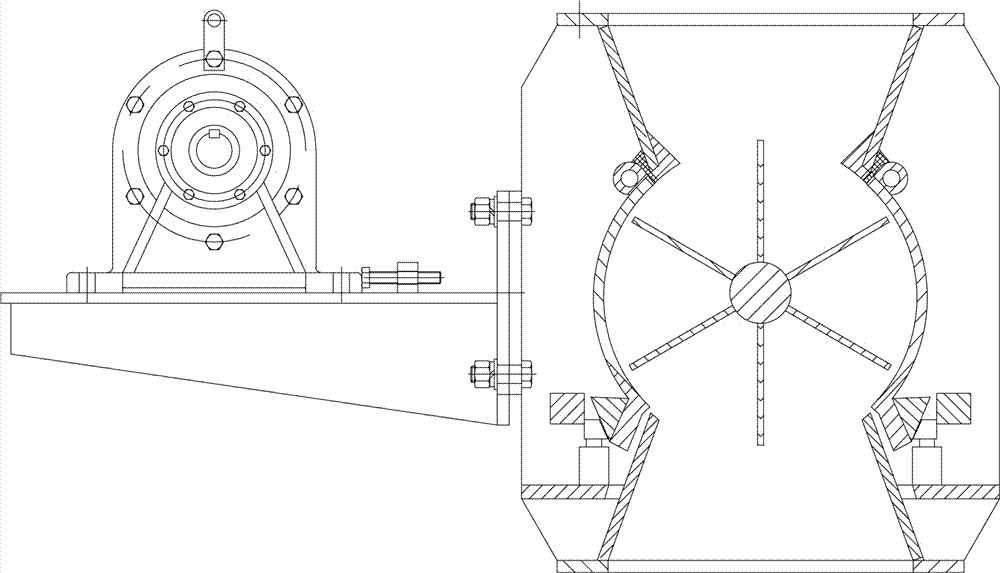

[0013] Such as Figures 1 to 3 As shown, an automatic miscellaneous feeder includes a valve body 1, a transmission shaft 7, an impeller 6 and a drive motor 8, and a speed sensor 2 is connected to one end of the transmission shaft 7, and the speed sensor 2 transmits the detected signal to the PLC for control 3, the PLC controller 3 controls the forward and reverse rotation of the drive motor 8.

[0014] The working principle of the present invention is: the normal operating speed of the impeller 6 feeder is 30r / min, and the overload speed of 28r / min can be preset in the PLC controller 3 . When the impeller 6 feeder is in normal operation, when impurities are stuck in the gap between the impeller 6 and the valve body 1, the speed of the impeller 6 will become slower and slower. When the feeder speed is lower than 28 r / min , the PLC controller 3 controls the drive motor 8 to stop for 1 second, then the PLC controller 3 controls the drive motor 8 to reverse for 1 second, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com