Tunnel crane

A technology for cranes and tunnels, which is applied in the direction of cranes, traveling bridge cranes, load suspension components, etc., and can solve the problems of rising construction costs, increased construction volume, and the lack of track lifting operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

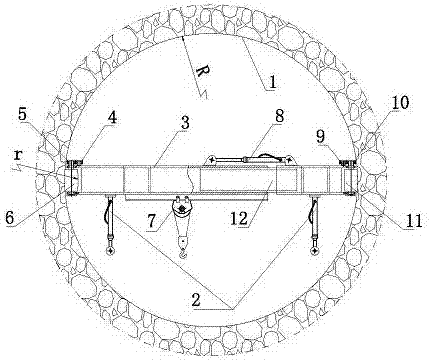

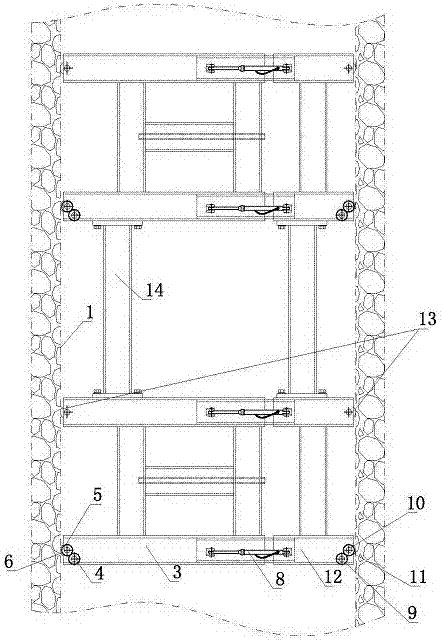

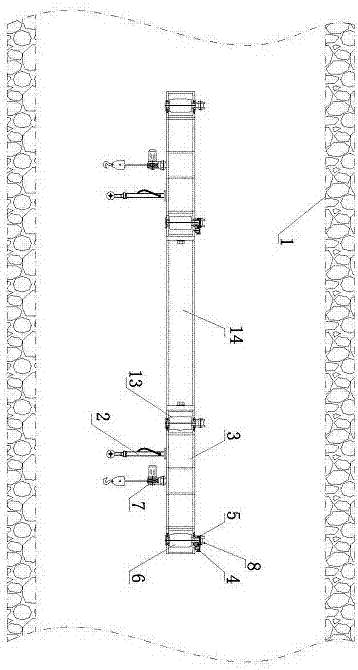

[0014] figure 1 , figure 2 and image 3 In the shown tunnel crane, the girder includes an outer girder 3 and an inner girder 12, the connecting end of the outer girder 3 can be slidably socketed on the connecting end of the inner girder 12, and on the girder A telescopic oil cylinder 8 is provided, and one end of the telescopic oil cylinder 8 is twisted and supported on the outer beam frame 3 , and the other end of the telescopic oil cylinder 8 is twisted and supported on the inner layer beam frame 12 . A rotatable left driving roller 6 is arranged on the supporting end of the outer beam frame 3, and a left driving gear 5 is fixedly arranged on the left driving roller 6, and the left driving gear 5 meshes with the left driving gear 4, and the left driving gear 4. Fixedly connected to the hydraulic motor; a rotatable right driving roller 11 is arranged on the support end of the inner beam frame 12, and a right transmission gear 10 is fixedly arranged on the right driving rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com