Universal clamp for clothes template machine

A garment template machine, a versatile technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of increasing cloth processing cost, low adjustment flexibility, unsatisfactory clamping effect, etc., and achieves improved clamping. effect, increase the flexibility of adjustment, and increase the effect of the machinable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

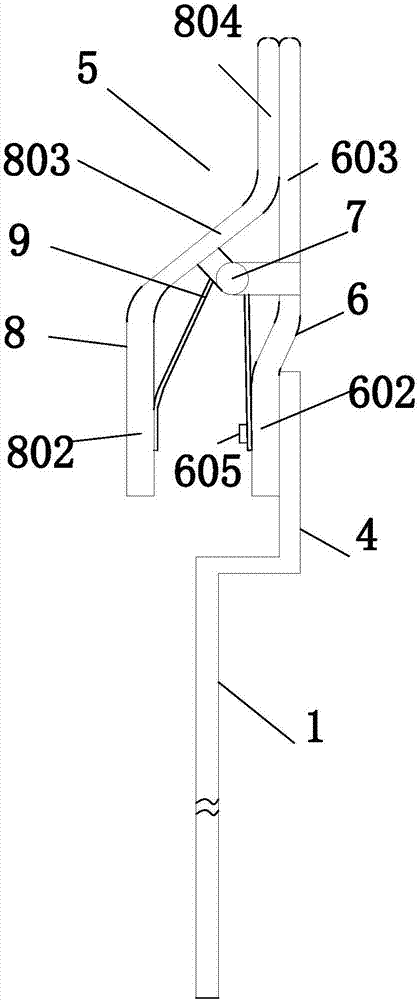

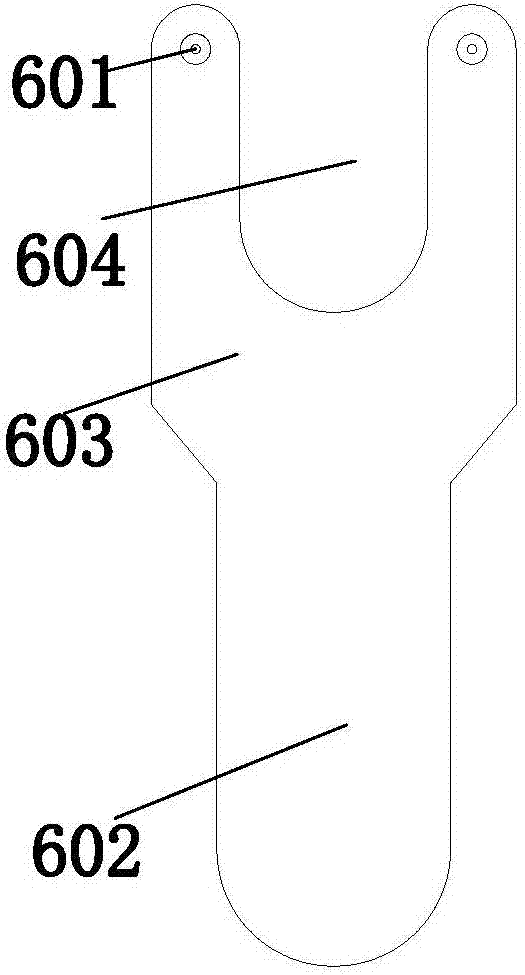

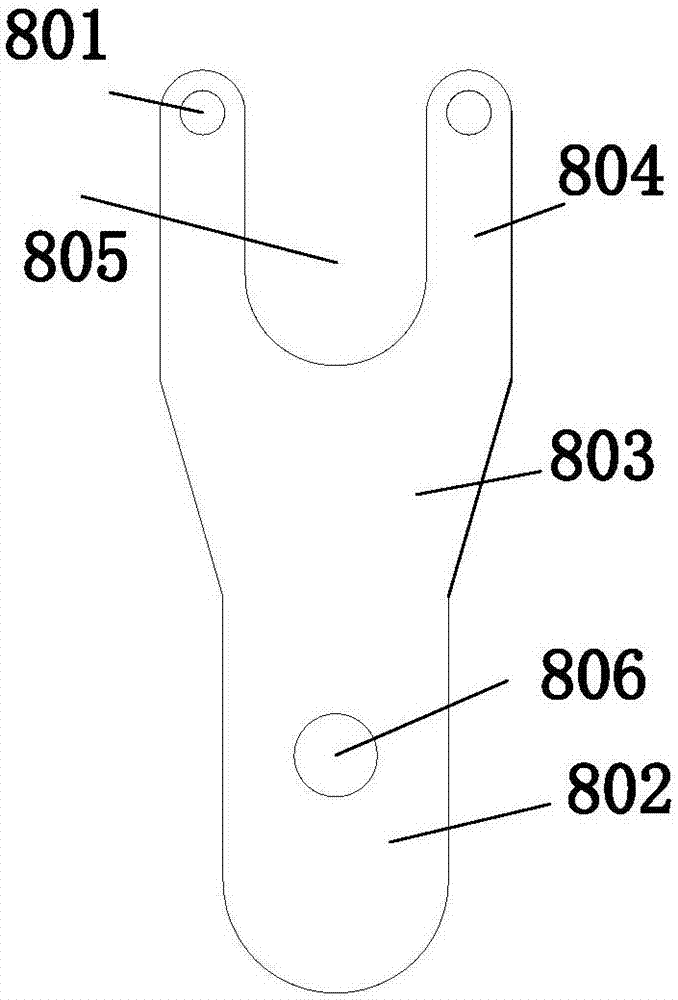

[0017] Example. A kind of universal clamp for clothing template machine, which is composed of Figure 1 to Figure 4 As shown, including the fixed piece 1, the fixed piece 1 is provided with an oblong hole 2, one end of the fixed piece 1 is provided with an arc edge 3, the other end of the fixed piece 1 is provided with a connecting piece 4 of a hemming structure, and the connecting piece 4 is provided with Collet 5; said collet 5 comprises a fixed collet 6 fixed to the connecting piece 4, the fixed collet 6 is hinged with a movable collet 8 through a hinge shaft 7, and a torsion spring 9 is sleeved on the hinge shaft 8, and the torsion spring 9 is sleeved on the hinge shaft 8. The two protruding ends of the spring 9 are in contact with the inner surfaces of the movable chuck 8 and the fixed chuck 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap