Transmission device capable of converting rotational motion into reciprocating variable rectilinear motion

A technology of linear motion and rotary motion, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems such as the inability of the rotor to rotate, the difficulty of linear motion, and the inability of the crank to rotate at a certain angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

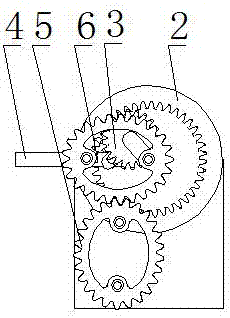

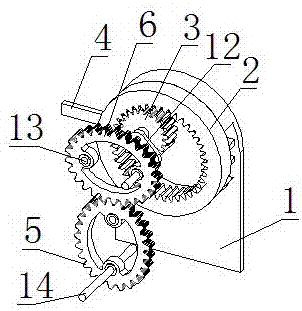

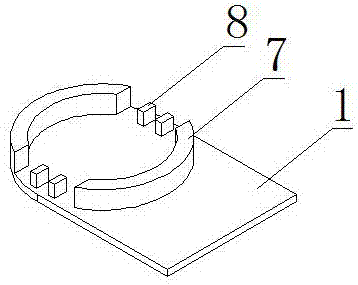

[0023] The transmission device for converting rotary motion into reciprocating variable-speed linear motion includes frame 1, sun gear 2, planetary gear 3, guide rod 4, non-circular gear A5 and non-circular gear B6. The central gear 2 is fixedly mounted on the frame 1 through the mounting seat 7, and the mounting seat 7 is composed of two semicircular arc plates arranged symmetrically. A guide rod 4 is slidably installed on the frame 1 between the mounting bases 7 through symmetrically arranged sliders 8;

[0024] The sun gear 2 is provided with a planetary gear 3 meshed with it, and the number of teeth of the sun gear 2 is twice the number of teeth of the planetary gear 3 . The central part of the planetary gear 3 is provided with an assembly hole 10, and the rear end surface of the planetary gear 3 on the side of the assembly hole 10 is provided with a guide rod seat 11. active connection. A Z-shaped planetary carrier 12 is fixedly mounted on the assembly hole 10 on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com