Forced-sealing ball valve and valve ball height adjusting mechanism thereof

A technology of height adjustment mechanism and forced sealing, which is applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve problems such as laborious and laborious, and affect production efficiency, and achieve simple and convenient operation, improve adjustment efficiency, and simple and easy verification operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

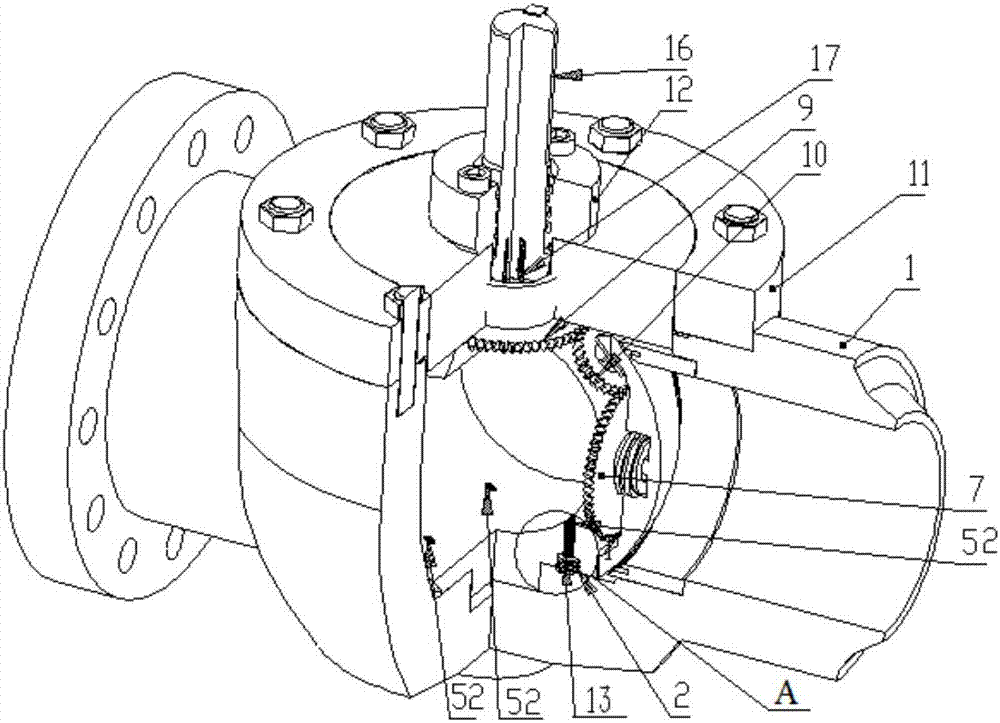

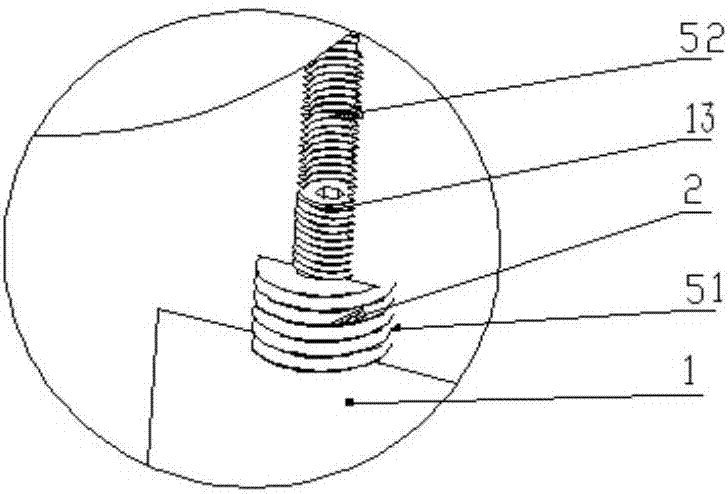

[0028] The invention provides a forced sealing ball valve and its valve ball height adjustment mechanism, which can adjust the height of the valve ball through the height adjustment part when the cumulative tolerance of each part has been fixed, the operation is simple and convenient, and the assembly and debugging work is greatly improved. efficiency.

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

[0030] The up and down mentioned in this article refer to the use state of the forced sealing ball valve. When the forced sealing ball valve is in use, the direction vertically pointing to the ground is down, and the direction vertically away from the ground is up.

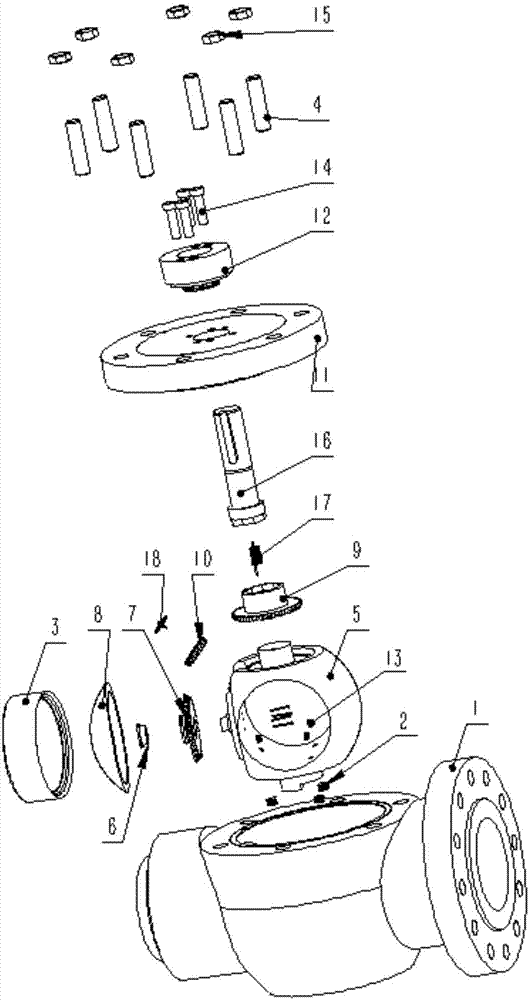

[0031] Such as Figure 1-Figure 7 As shown, the present invention provides a forced sealing ball valve, which includes a valve body 1 for fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com