Double-free-form-surface optical lens for LED (Light-emitting Diode) automobile dipped headlight

An optical lens and low beam technology, which is applied to the parts of lighting devices, lighting devices, refractors, etc., can solve the problems of cut-off line dispersion, high color temperature, unclear cut-off line, etc., and achieve smooth appearance and uniform lighting spot. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the implementation and protection of the present invention are not limited thereto.

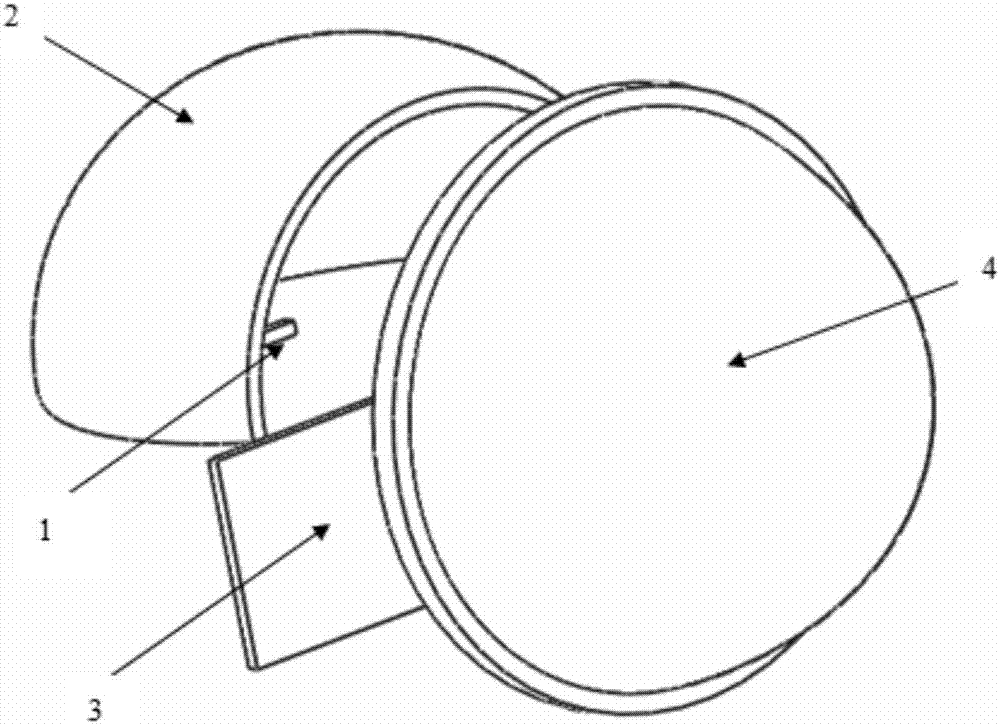

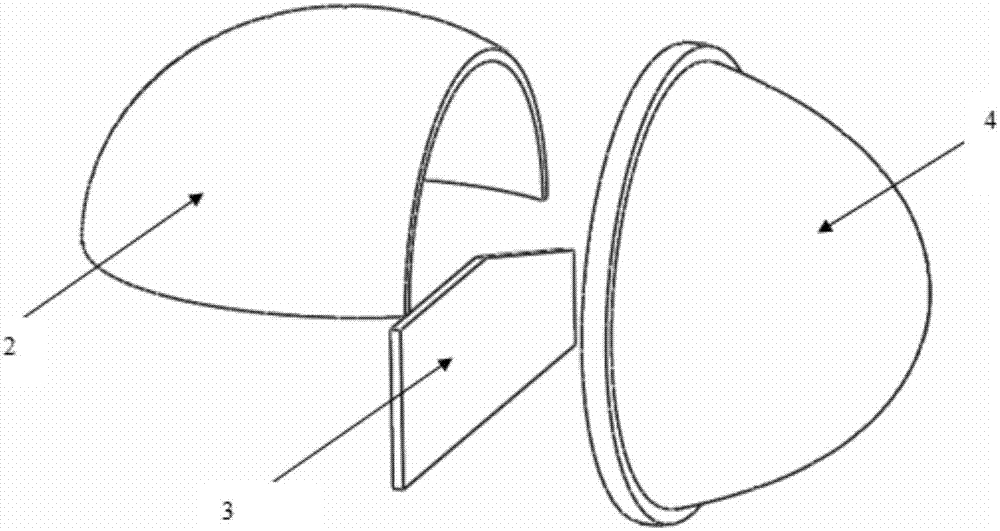

[0031] Double free-form surface optical lens for LED car low beam. The upper and lower surfaces of the lens are free-form surfaces. The first free-form surface is the incident surface, which replaces the incident plane in the single free-form surface, and the second free-form surface is the exit surface. The chip is placed at one focal point of the ellipsoidal reflector cup, the baffle is placed at the other focal point, and the lens is placed in front of the baffle. The role of the board, the stray light is blocked, the aggregated light is corrected by the lens and hits the lighting surface, and each free-form surface can flexibly correct the light, so that the lighting spot is more uniform, and the appearance of the curved surface is smooth; accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com