Concave-panel electromagnetic oven

A technology of induction cooker and concave plate, which is applied in the direction of household stove/stove, stove/stove top, electric heating fuel, etc., can solve the problem of inaccurate temperature measurement, and achieve the effect of avoiding misjudgment and accurate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

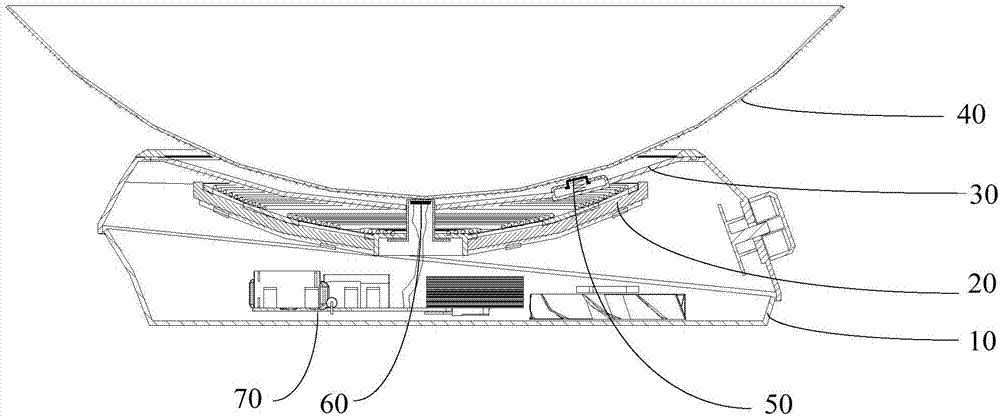

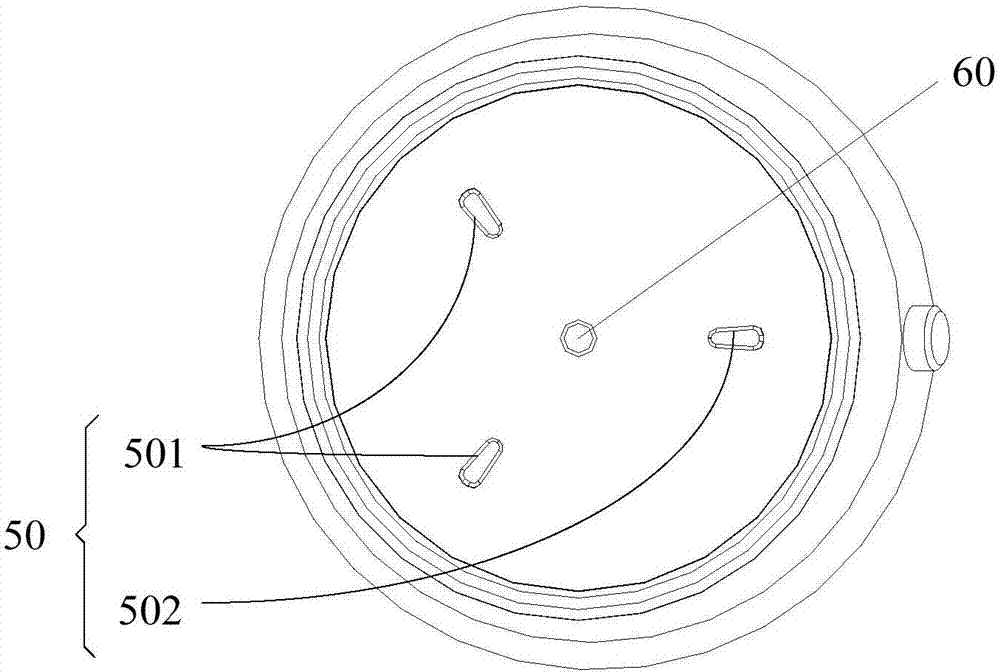

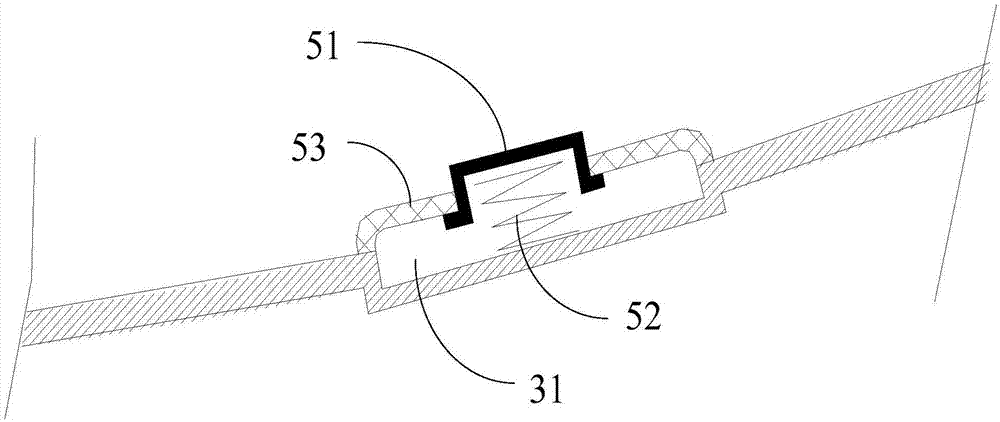

[0047] figure 1 It is a schematic cross-sectional structure diagram of the concave plate induction cooker provided in the first embodiment of the present invention, figure 2 It is a top-view structural schematic diagram of the concave panel in the concave plate induction cooker provided in the first embodiment of the present invention, image 3 It is a schematic diagram of the retractable support structure on the concave panel in the concave plate induction cooker provided in the first embodiment of the present invention, such as Figure 1-3 As shown, the concave disk induction cooker provided by the present invention includes: a bottom case 10, a concave coil disk 20 and a circuit board 70 are arranged in the bottom case 10, and a concave panel 30 matching the concave coil disk 20 is provided on the bottom case 10, wherein, In this embodiment, the concave surfaces of the concave coil disc 20 and the concave panel 30 are arc surfaces with a certain radian, and the concave su...

Embodiment 2

[0059] Figure 4 It is a schematic diagram of the retractable support structure on the concave panel in the concave induction cooker provided by the second embodiment of the present invention. When the cover body 53 is set on the notch of the groove 31, the cover body 53 and the concave panel 30 need to carry out connected, but during use, there is often a collision between the cover 53 and the bottom of the pot 40, and the cover 53 is always in a high state during the use of the pot 40, so the cover 53 and the concave shape Looseness easily occurs between the panels 30, and even the cover body 53 falls off from each concave panel 30. In this embodiment, in order to prevent the cover body 53 from falling off during use, as Figure 4 As shown, the difference between this embodiment and the first embodiment above is that in this embodiment, the concave side wall of the concave panel 30 has an outwardly protruding bending section 32, such as Figure 4 As shown, the bending secti...

Embodiment 3

[0064] Figure 5 It is a schematic diagram of the retractable support structure on the concave panel in the concave-pan induction cooker provided by Embodiment 3 of the present invention, as Figure 5 As shown, in this embodiment, the stretchable support structure 502 is an elastic piece 56, wherein, one end of the elastic piece 56 is connected to the side wall of the concave panel 30, and the other end of the elastic piece 56 is suspended, specifically, as Figure 5 As shown, a concave space 57 is formed on the concave side wall of the concave panel 30, one end of the elastic piece 56 is connected to the bottom end of the side wall of the concave space 57, the middle of the elastic piece 56 protrudes outward, and the other end of the elastic piece 56 is suspended in the air. On the other side of the concave space 57, when the pot 40 is placed on the concave panel 30, the pot 40 exerts a downward force on the elastic piece 56, so that the elastic piece 56 is compressed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com