Process cartridge and regeneration method thereof

A process box and development frame technology, applied in electrography, optics, instruments, etc., can solve the problems of increasing the complexity of the production process and the difficulty of installation, the complex structure and process of the second driving force transmission component, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

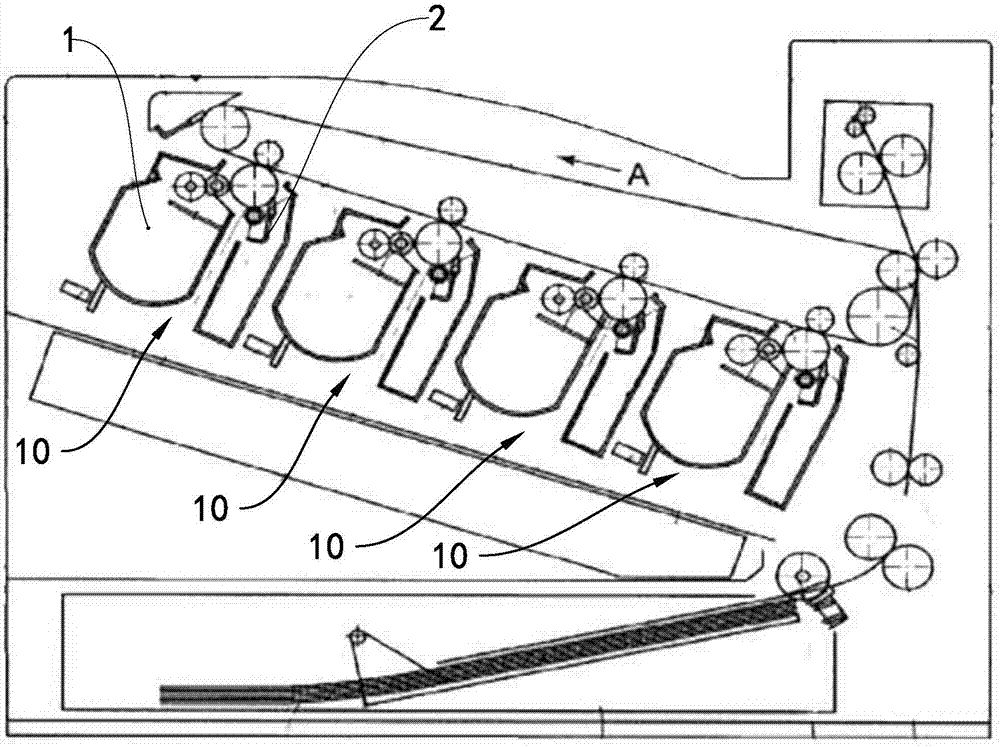

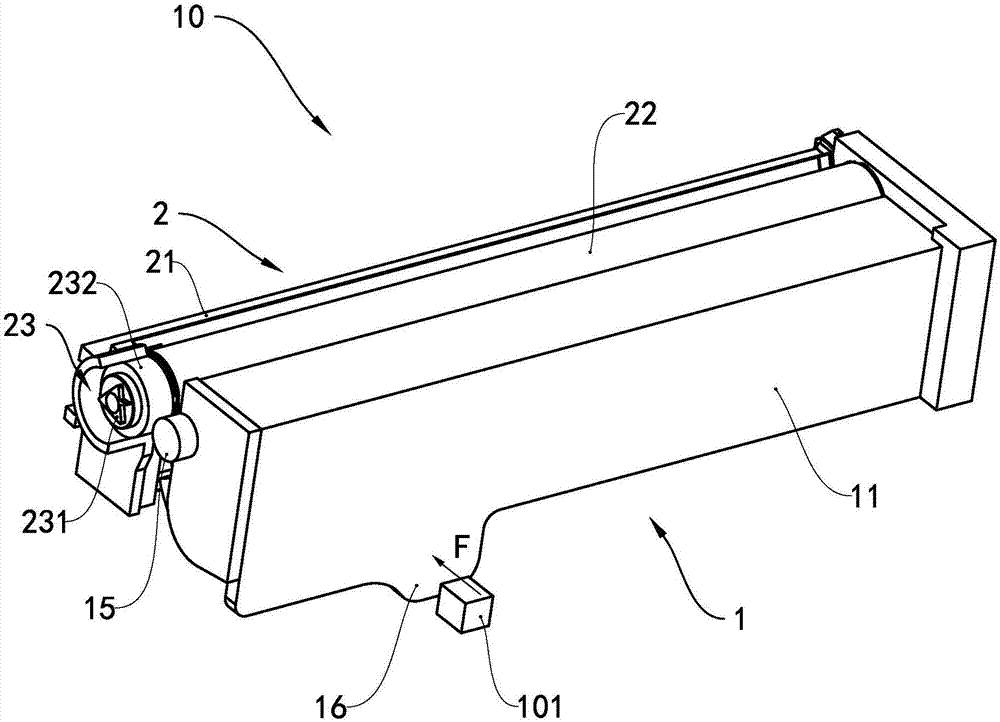

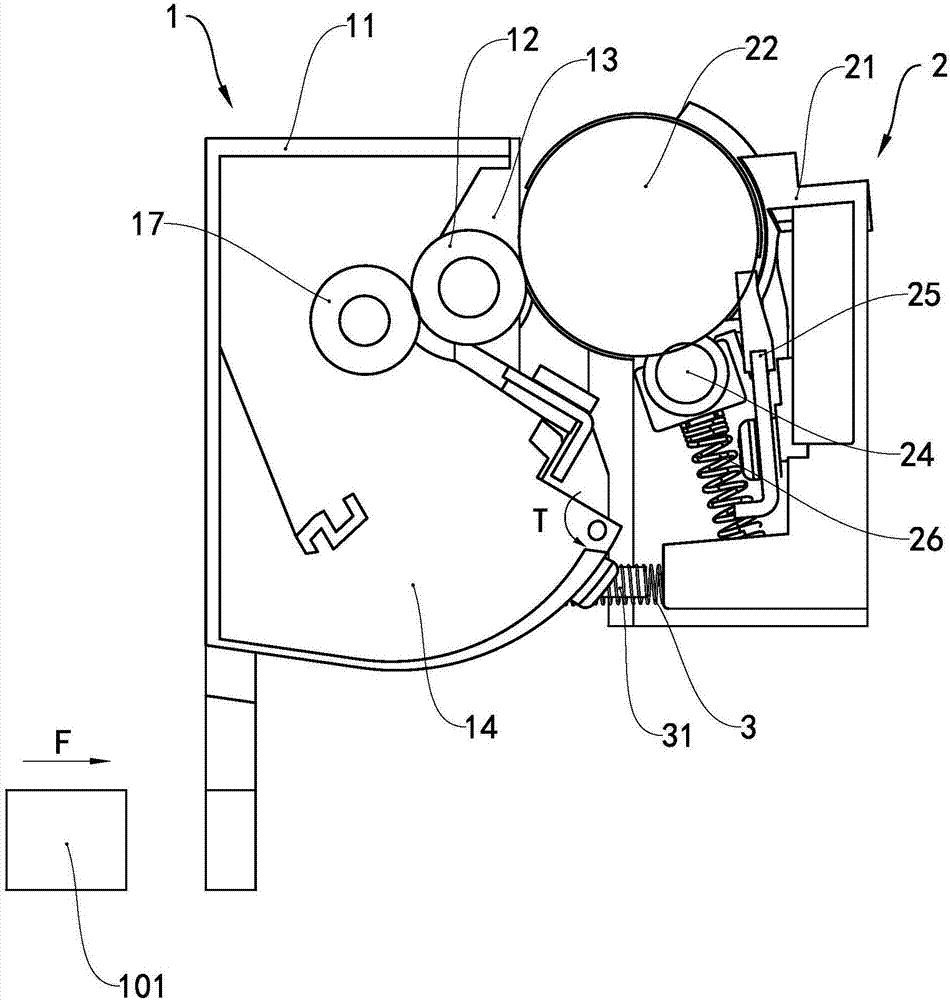

[0033] see Figure 1 to Figure 3 , figure 1A state in which the process cartridge of this embodiment is installed in a printer is shown, the process cartridge 10 includes a developing unit 1 and a drum unit 2, the developing unit 1 includes a developing frame 11 and a developing roller 12 rotatably supported on the developing frame 11, The developing frame 11 has a developing chamber 13 and a toner containing chamber 14. The developing chamber 13 is located above the toner containing chamber 14. The developing roller 12 is located in the developing chamber 13. A powder feeding roller 17 is also arranged in the developing chamber 13. The powder roller 17 is arranged parallel to the developing roller 12 , and the outer peripheral surface of the powder feeding roller 17 is in contact with the outer peripheral surface of the developing roller 12 . The drum unit 2 includes a cleaning frame 21, a photosensitive drum 22 and a charging roller 24 rotatably supported on the cleaning fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com