Calculation method of supersonic turbulent combustion flow based on flame surface/progress variable model

A calculation method and supersonic technology, applied in the field of computational fluid dynamics, which can solve problems such as difficulty in establishing compressible correction of flame surface/progress variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

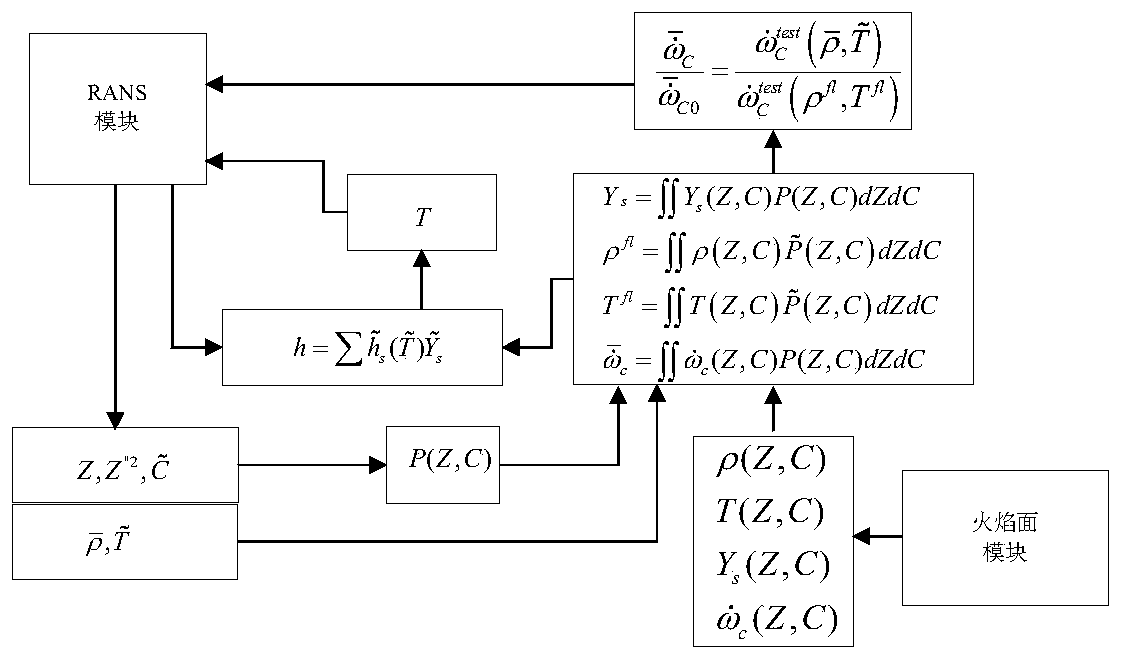

Method used

Image

Examples

Embodiment

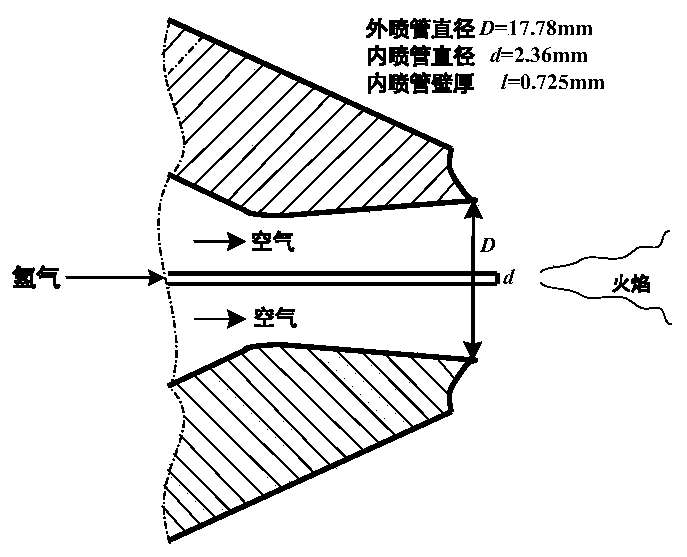

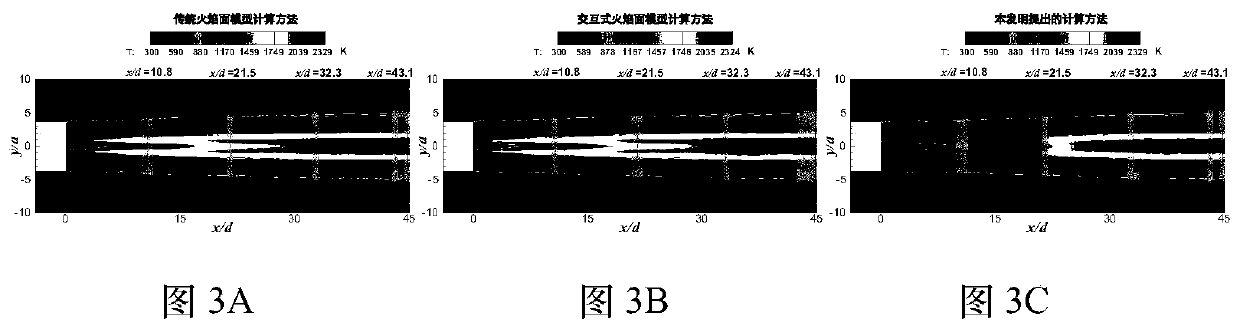

[0067] Using the novel supersonic turbulent combustion flow calculation method based on the flame surface / progress variable model proposed by the present invention, the figure 2 and Figure 6 The two calculation examples shown containing the experimental data of supersonic turbulent combustion were calculated and analyzed respectively. The experimental device used in Example 1 is as follows: figure 2 As shown, hydrogen is injected into the air through concentric tubes to form a supersonic axisymmetric diffusion combustion flow. Air flow conditions are: Mach number 2, temperature 1250K, pressure 107kPa; hydrogen incident velocity is the speed of sound. Figure 3 first gives the temperature cloud images obtained by different calculation methods. Among them, SF model is a traditional flame surface model calculation method, RIFmodel is an interactive flame surface model calculation method, and FPV model is a calculation method proposed by the present invention. The RIF model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com