Thin switch

A thin switch and contact shrapnel technology, applied in the field of switches, can solve the problems of large overall thickness, uneven force, slow response, etc., and achieve the effect of less overall component composition, increased use feeling, and less component composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

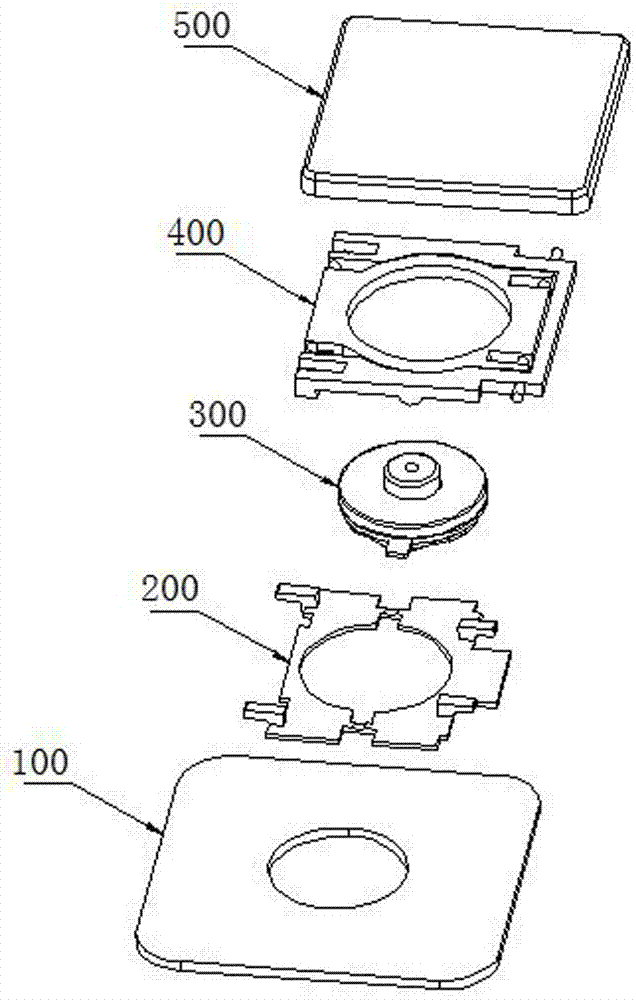

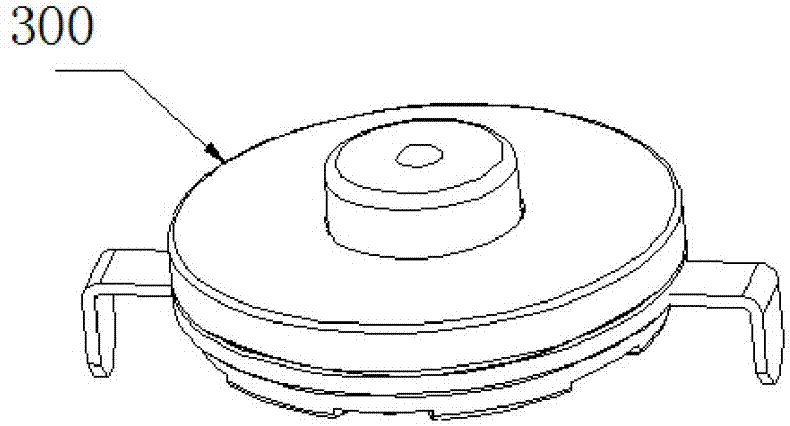

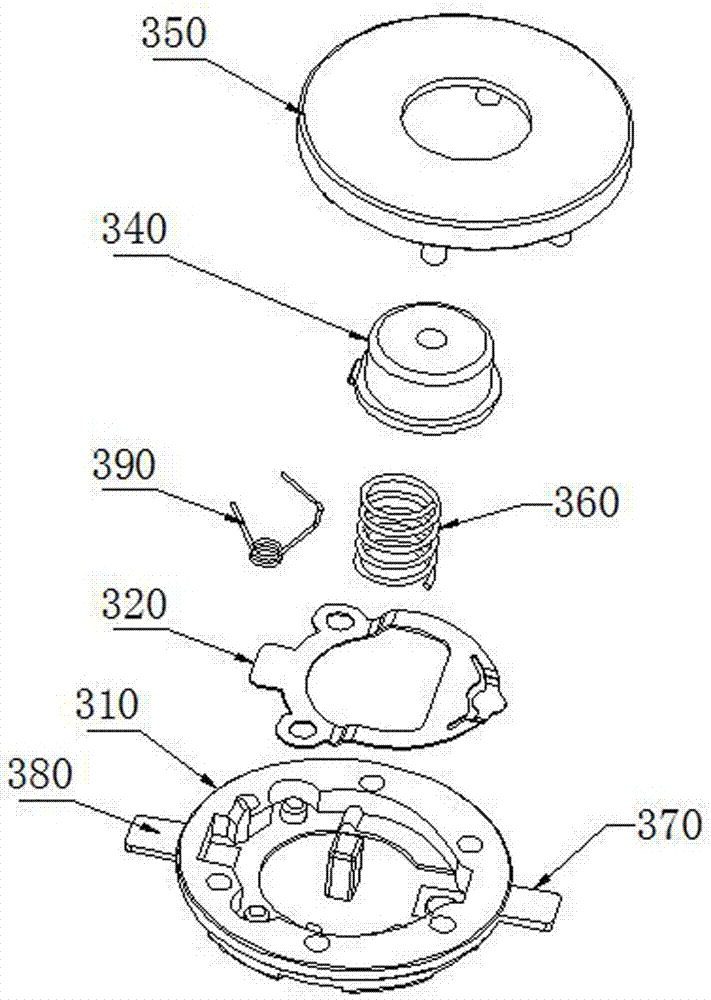

[0046] like Figure 1 to Figure 9 As shown, a thin switch, the thin switch 300 is connected to the circuit board 100 on the keyboard, the keyboard includes: a bottom plate assembly, the bottom plate assembly includes a circuit board 100 and a support plate 200; a plurality of keys, the The buttons are arranged on the base plate assembly, and each button is provided with: a keycap 500 in sequence from top to bottom; Contact connection, the bottom of the scissors feet 400 is connected with the support plate 200; a thin switch 300 connected with the circuit board 100, the thin switch 300 includes: a cover 350, the center of the cover 350 is provided with a button hole 351; Push button 340, the button button 340 is loaded into the button button hole 351 on the cover 350; a base 310, the base 310 is connected with the cover 350 by riveting, and the center of the base 310 is provided with a housing groove for contact shrapnel 315, the base groove wall 311 is surrounded by the conta...

Embodiment 2

[0053] like figure 1 , Figure 11 to Figure 15 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, a single-hole torsion spring 390 is used as the sound member, and the single-hole torsion spring 390 includes a second spring positioning The hole 391 , a second guiding portion 392 arranged obliquely and a third guiding portion 393 , the second guiding portion 392 is in contact with the arc-shaped extrusion contact 342 . On the base groove wall 311 between the upper moving terminal 380 of the base 310 and the base positioning hole 316 on one side, a sound piece guide column 318 is provided, and the sound piece guide column 318 is provided with a sound piece on the side corresponding to the sound piece. The member guiding inclined surface 319 is in contact with the third guiding portion 393 on the single-hole torsion spring 390 . The structure and principle of this embodiment are bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com