Mini-type acoustical generator

A sounder and micro technology, applied in the direction of fixing/tensioning of sensors, electrical components, diaphragms, etc., can solve the problem that it cannot be installed on the side wall of the casing, but can only be set at the bottom of the micro sounder, the micro sounder Unable to meet the problems of portable electronic equipment and micro sounder leaving airflow and other problems, to achieve the effect of expansion performance, good sealing and high waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0034] The inner refers to the position close to the center of the micro-sounder, and the outer refers to the position away from the center of the micro-sounder; the direction "up" refers to the direction where the vibration system is installed, and the direction "down" refers to the direction where the magnetic circuit is installed. system orientation.

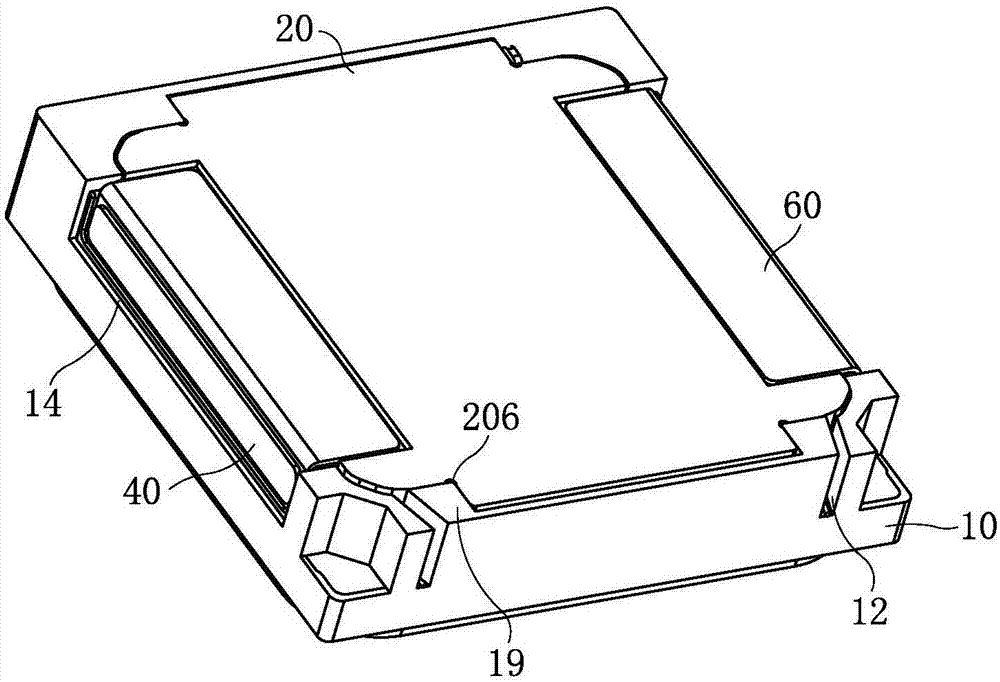

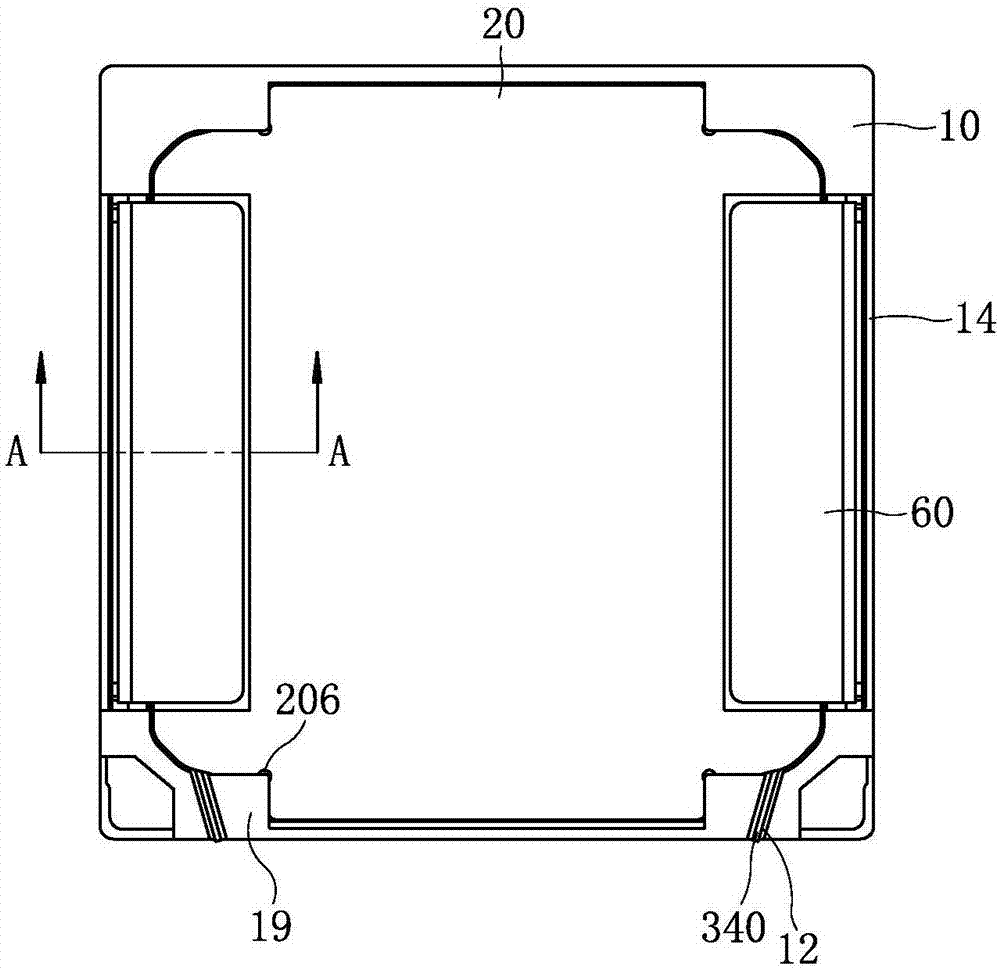

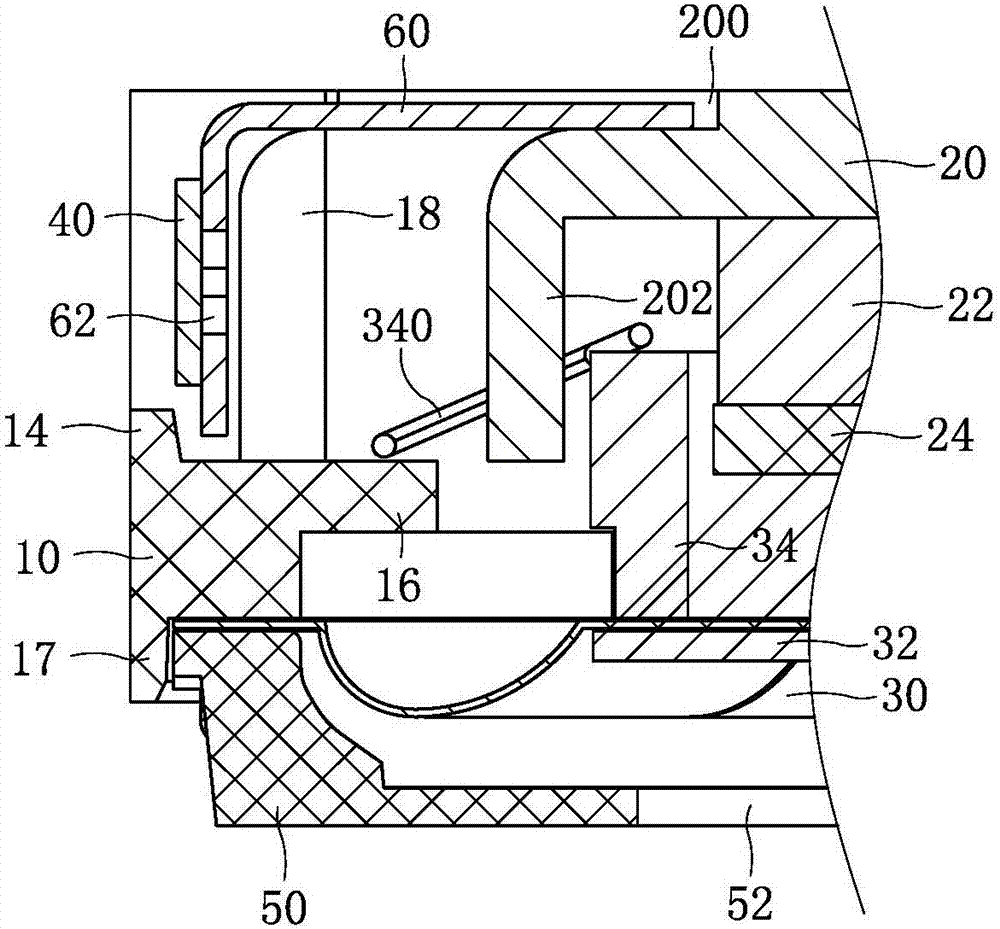

[0035] like figure 1 , figure 2 , image 3 and Figure 7 As shown together, a miniature sound generator includes a ring-shaped casing 10 , the casing 10 has a square structure, and a front cover 50 is combined at the upper end of the casing 10 . A vibration system and a magnetic circuit system are accommodated in the space jointly enclosed by the casing 10 and the front cover 50 . The vibration system includes a diaphragm 30 and a voice coil 34, the edge of the diaphragm 30 is fixed between the upper end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com