A linear constant current drive circuit

A linear constant current drive and circuit technology, applied in electric light sources, electrical components, electroluminescent light sources, etc., can solve problems such as high power factor and low harmonic distortion, achieve high power factor, low harmonic distortion, avoid The effect of LED overcurrent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

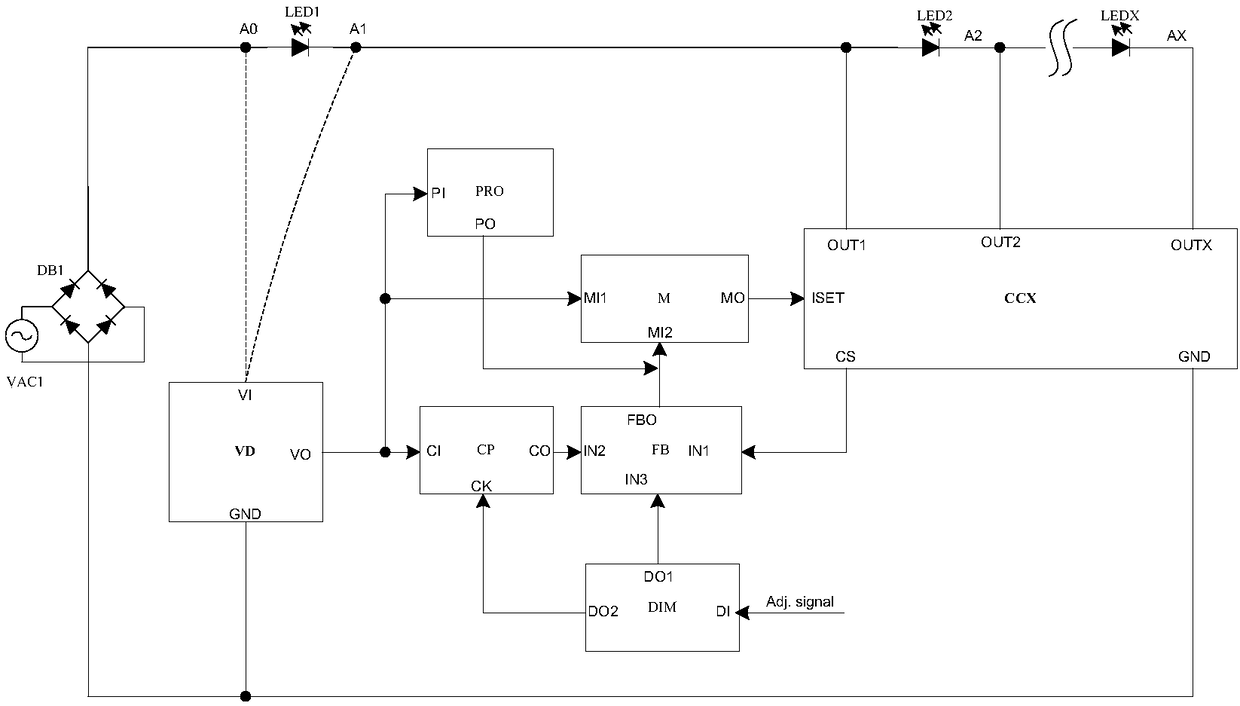

[0037] figure 1 It is a schematic diagram of the principle of the linear constant current drive circuit of the first embodiment.

[0038] Such as figure 1 As shown, LED1, LED2, and LEDX are connected in series in sequence to form a load, forming an anode node A0 and several cathode nodes A1, A2, and AX. The input terminal of the rectifier bridge DB1 is connected to the mains VAC1, and the output positive pole is connected to the anode node A0. The negative pole is grounded, and the drive circuit includes: switching constant current source CCX, voltage detection circuit VD, feedback circuit FB, multiplier M, constant power compensation circuit CP, protection circuit PRO and dimming circuit DIM.

[0039] The switching constant current source CCX includes a current setting terminal ISET for setting the current of the switching constant current source, a common ground GND, a current detection terminal CS for responding to switching the constant current source current, and several...

Embodiment 2

[0082] In the second embodiment, except that the structure of the protection circuit PRO is different from that of the first embodiment, other circuit structures and working principles are the same, and will not be described again.

[0083] Figure 8 It is a circuit diagram of the protection circuit PRO of the second embodiment.

[0084] Such as Figure 8 As shown, the protection circuit PRO includes a filter F8, an amplifier AMP8 and a transistor Q8. The input terminal of the filter F8 is connected to the input terminal PI of the protection circuit PRO, the output terminal is connected to the inverting input terminal of the amplifier AMP8, the output terminal of the amplifier AMP8 is connected to the gate of the transistor Q8, the source of the transistor Q8 is grounded, and the amplifier Both the non-inverting input terminal of AMP8 and the drain of transistor Q8 are connected to the output terminal PO of the protection circuit PRO.

[0085] The input terminal PI of the p...

Embodiment 3

[0087] In the third embodiment, except that the structure of switching the constant current source CCX is different from that of the first embodiment, other circuit structures and working principles are the same, and will not be described again.

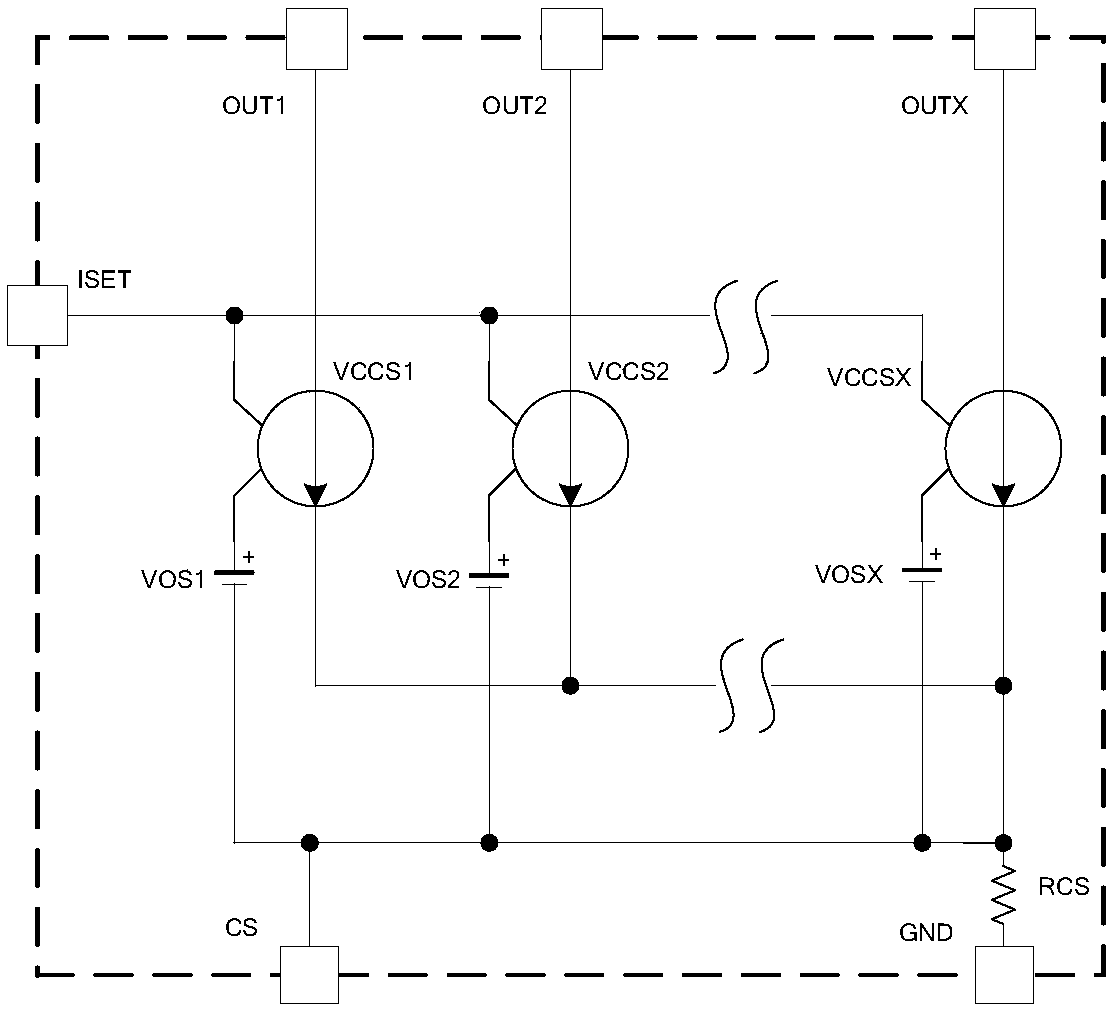

[0088] Figure 9 It is the circuit diagram of the switching constant current source CCX of the third embodiment.

[0089] Such as Figure 9 As shown, will figure 2 The second control terminal of each voltage-controlled current source in the switching constant current source CCX circuit shown is respectively connected to one end of several signal bias sources VOS1, VOS2 and VOSX, and several signal bias sources VOS1, VOS2 and VOSX The other ends of are connected to the current setting terminal ISET, then can realize and figure 2 same function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com