Desulfurization and denitrification system

A desulfurization and denitrification, desulfurization tower technology, applied in the field of desulfurization and denitrification system, can solve the problems of inapplicability, coking furnace does not have the SNCR temperature range, etc., to achieve the effect of saving costs, saving investment funds, and good denitrification effect

Inactive Publication Date: 2017-11-28

NANTONG CHUNGUANG AUTOMATIC CONTROL EQUIP ENG

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 1. SCR method: the flue gas temperature requirement is 340°C-380°C, and the flue gas temperature of many industrial kilns is lower than the temperature range required by SCR. SCR denitrification technology is not suitable for industrial kiln flue gas

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

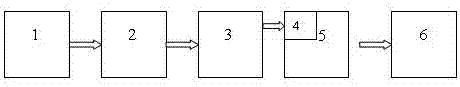

The invention provides a desulfurization and denitrification system. The desulfurization and denitrification system includes an oxidizing agent preparation system (1), an oxidizing agent solution transportation and metering system (2) connected to the oxidizing agent preparation system, a compressed air system (3) connected to the oxidizing agent solution transportation and metering system, an injection system (4) connected to the compressed air system (3), a flue (5) for flue gas transportation and flue gas denitrification, and a desulfurizing tower (6) for desulfurization. The injection system (4) is used for spraying the oxidizing agent, and is disposed in the flue (5). The desulfurization and denitrification system provided by the invention has the following technical effects that: 1) the system greatly saves the cost: a denitrification tower is eliminated, the method of denitrification by spraying an oxidizing agent in the flue can save more than 1 million of invest capital, by spraying the oxidizing agent in the flue, the project can be realized only with tens of thousands of investment; and 2) the system solves the existing technical problems: without additional heating, the system can achieve denitrification, and can solve the problem of difficult utilization of SCR and SNCR for denitrification in industrial kilns; and 3) the denitrification effect is good.

Description

technical field [0001] The invention relates to a desulfurization and denitrification system, belonging to the technical field of environmental protection equipment. Background technique [0002] Flue gas desulfurization and denitrification technology is a boiler flue gas purification technology applied in the chemical industry that produces many nitrogen oxides and sulfur oxides. Nitrogen oxides and sulfur oxides are one of the main sources of air pollution. Therefore, the application of this technology has many benefits for ambient air purification. [0003] At present, the background of the desulfurization and denitrification industry at home and abroad is relatively good. my country's development of flue gas desulfurization and denitrification industry policies and market demand prospects are promising, and the market potential is relatively large. Investing in this industry faces strong market feasibility and economic feasibility. The rapid development of the desulfur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/79B01D53/56

CPCB01D53/79B01D53/56B01D2251/104B01D2251/106B01D2251/108B01D2251/304

Inventor 陆俊华陆宝林

Owner NANTONG CHUNGUANG AUTOMATIC CONTROL EQUIP ENG

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com