Multi-welding-spot alloy welding powder coating mechanism capable of adjusting coating thickness

A technology of coating thickness and coating, which is applied in the direction of welding/welding/cutting articles, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity, high economic cost and low operation efficiency of operators, and achieve the goal of lifting rollers Coating efficiency, uniform thickness of roller coating, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

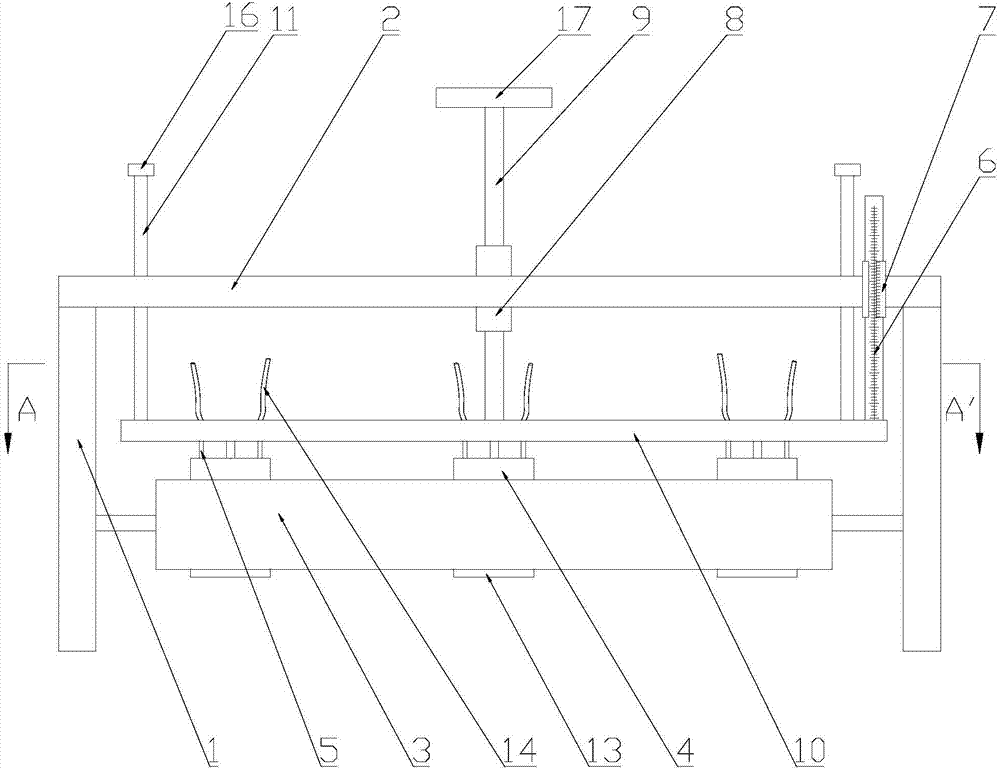

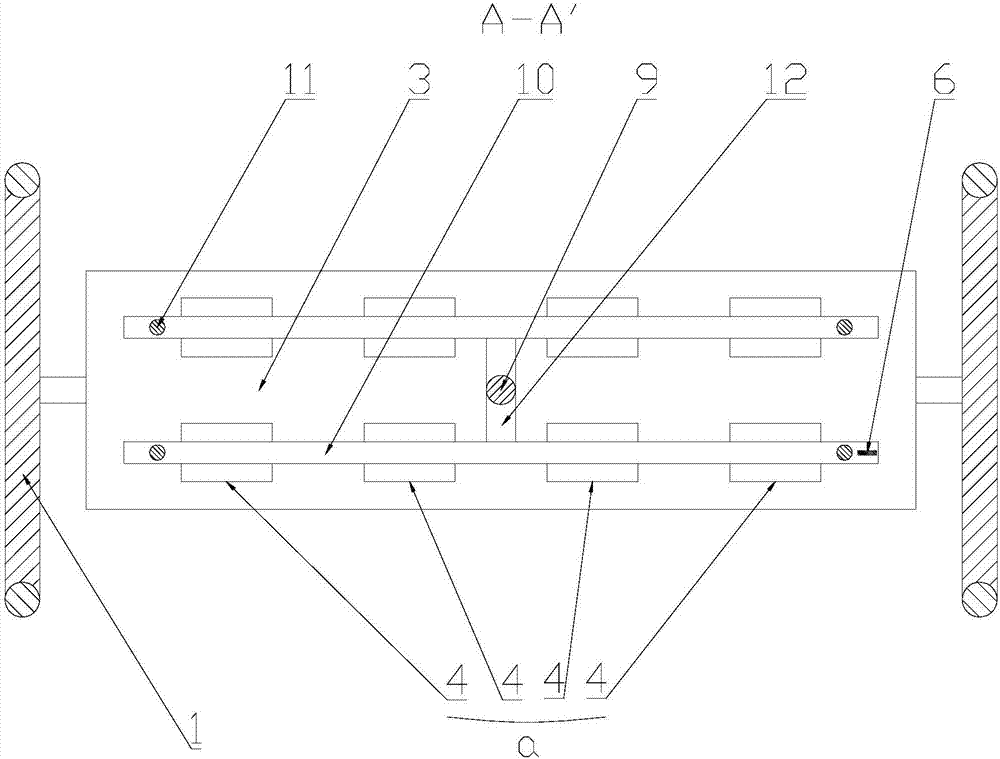

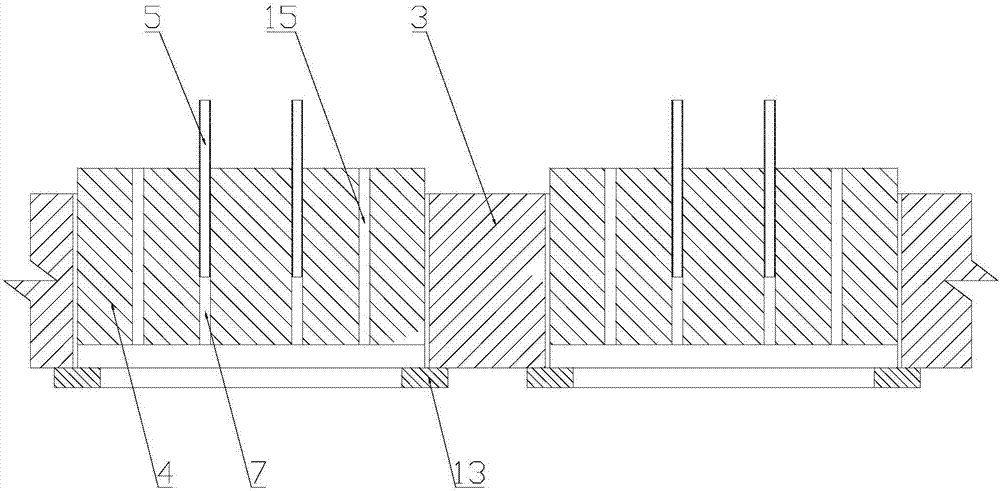

[0018] The present invention will be further described below with reference to the embodiments and accompanying drawings.

[0019] like Figure 1-Figure 3 As shown, a multi-spot alloy solder powder coating mechanism with adjustable coating thickness includes a support device on which a holding seat 3 is provided, and at least two coating Coating assembly a, a lifting device and a distance measuring device are arranged between the coating assembly a and the support device, all the coating assemblies a are connected with the lifting device through a synchronizing device, and the distance measuring device is used to measure the The lifting distance of the coating assembly a.

[0020] The support device includes a support frame 1 and a support plate 2, the support plate 2 is fixedly installed on the support frame 2, and the holder 3 is fixedly installed on the support frame under the support plate 2 through a connecting rod 1, the coating assembly a includes at least two blankin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap