Method for assembling frame assemblies

An assembly method and frame technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high assembly cost, low quality stability, poor efficiency, etc. The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

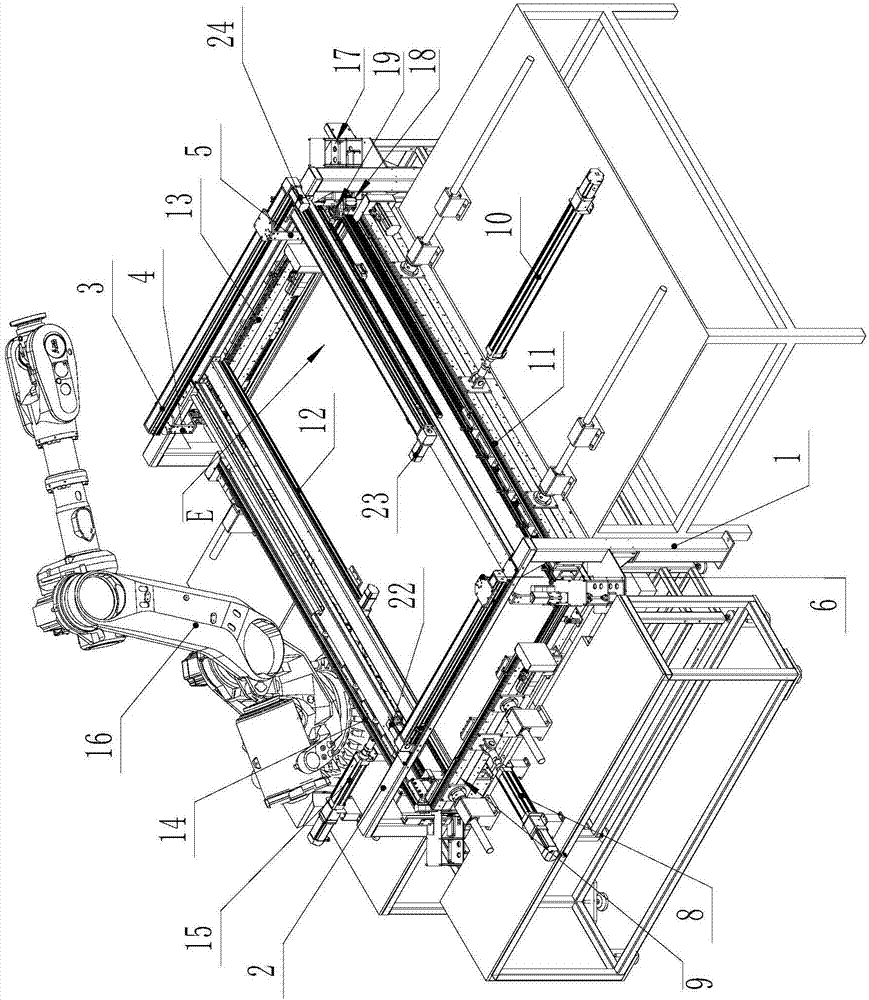

[0018] figure 1 It is a perspective view of the structure of the automatic framing device of Embodiment 2 of the present invention;

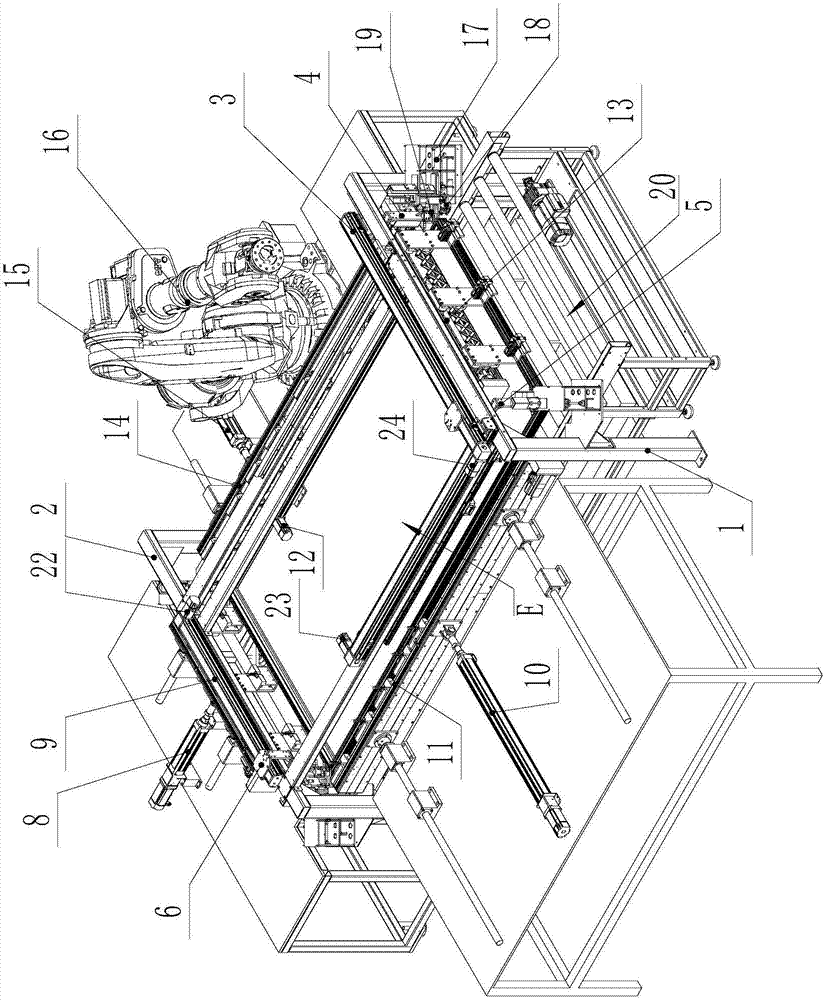

[0019] figure 2 It is a perspective view of another angle of the automatic framing device of Embodiment 2 of the present invention;

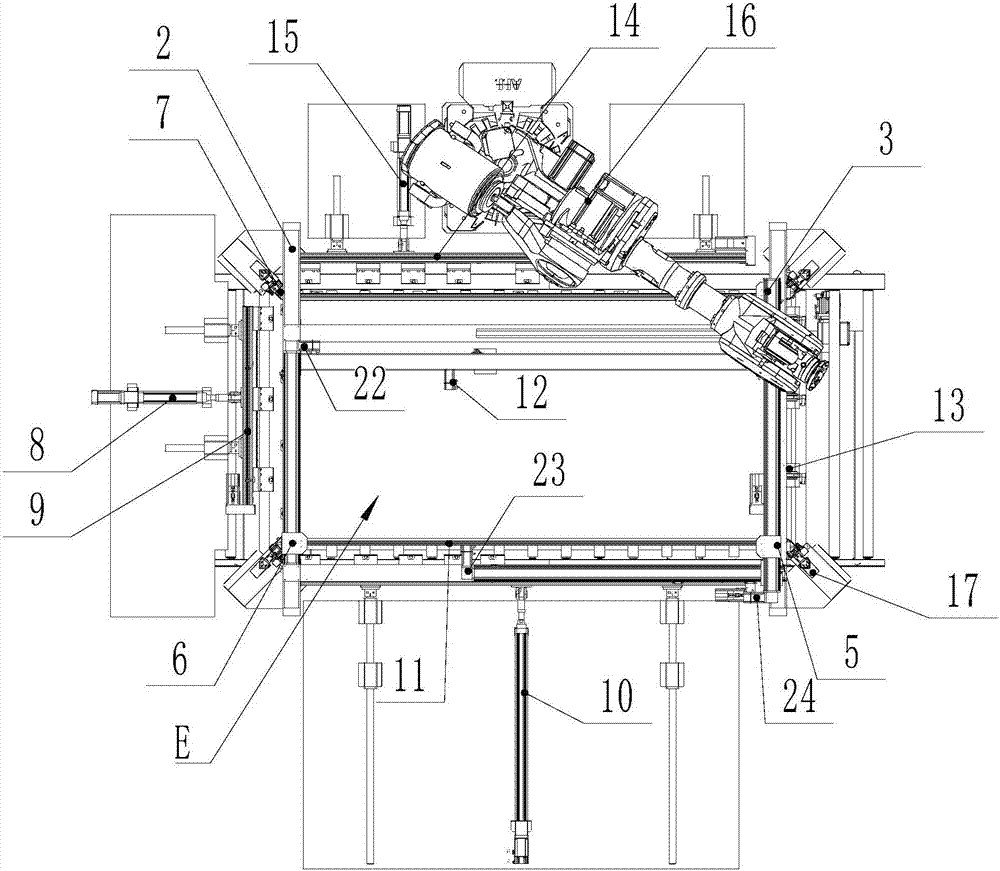

[0020] image 3 It is a top view of the automatic framing device of Embodiment 2 of the present invention;

[0021] Figure 4 It is a three-dimensional view of the structure of the components driving the action of the frame in Embodiment 2 of the present invention;

[0022] Figure 5 It is a top view of the components driving the action of the frame in Embodiment 2 of the present invention;

[0023] Figure 6 It is the structural diagram of the left frame clamping device of Embodiment 2 of the present invention;

[0024] Figure 7 It is the structural diagram of the right frame clamping device of Embodiment 2 of the present invention;

[0025] Figure 8 It is the side structural diagram when the right ...

Embodiment 1

[0053] This embodiment discloses a frame component assembly method, which defines a rectangular assembly area, corner brackets are set near each right angle of the assembly area, and the right-angle plate part of the corner bracket is connected to the right-angle side of the assembly area Correspondingly parallel; the left frame, right frame, front frame and rear frame are placed around the assembly area, and the two ends of each frame are complementary 45° mating surfaces; the height of the frame and corner code meets the assembly requirements, and the left frame faces The right and right frames move to the left, the front frame moves backward, and the rear frame moves forward synchronously. During the movement of each frame, the 45° mating surface at both ends of each frame first contacts with the corresponding right-angle plate part of the corner code so that the right-angle plate part enters When the frames continue to move, the corner brackets are driven to move to the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com