Automatic fluid preparation device for cutting fluid for machining center

An automatic liquid dispensing and processing center technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of wasting employee hours, increasing company costs, and unfavorable cleaning, so as to save water and configure cutting fluid Stabilize and reduce the effect of wrong proportion of human operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

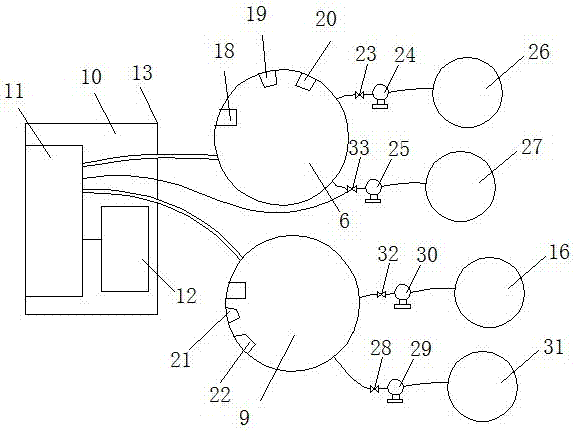

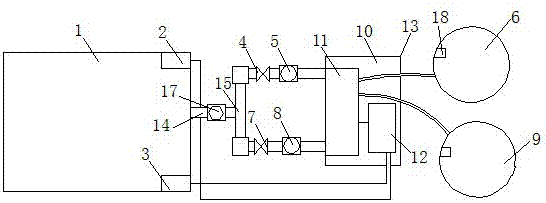

[0020] Such as figure 1 As shown, the cutting fluid automatic dispensing device of the machining center includes a chip fluid tank 1 installed on the machine tool table, and a mixed chip fluid reservoir connected to the chip fluid tank 1 through the chip fluid control box 10 to provide the chip fluid for it. Bucket A6 and mixed cutting fluid water storage bucket B9; a minimum liquid level sensor A19 and a maximum liquid level sensor A20 are respectively placed at the lowest liquid level and the highest liquid level of the mixed cutting fluid water storage bucket A6; the mixed cutting fluid water storage bucket A minimum liquid level sensor B21 and a maximum liquid level sensor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap