Visual carrier gas type roller powder feeder and powder feeding system

A powder feeder and carrier gas technology, which is applied in the field of visual carrier gas roller powder feeder and powder feeding system, can solve the problem of inability to intuitively perceive the adjustment of powder feeding amount, complicated structure of feeding device, easy blockage of powder feeding system, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

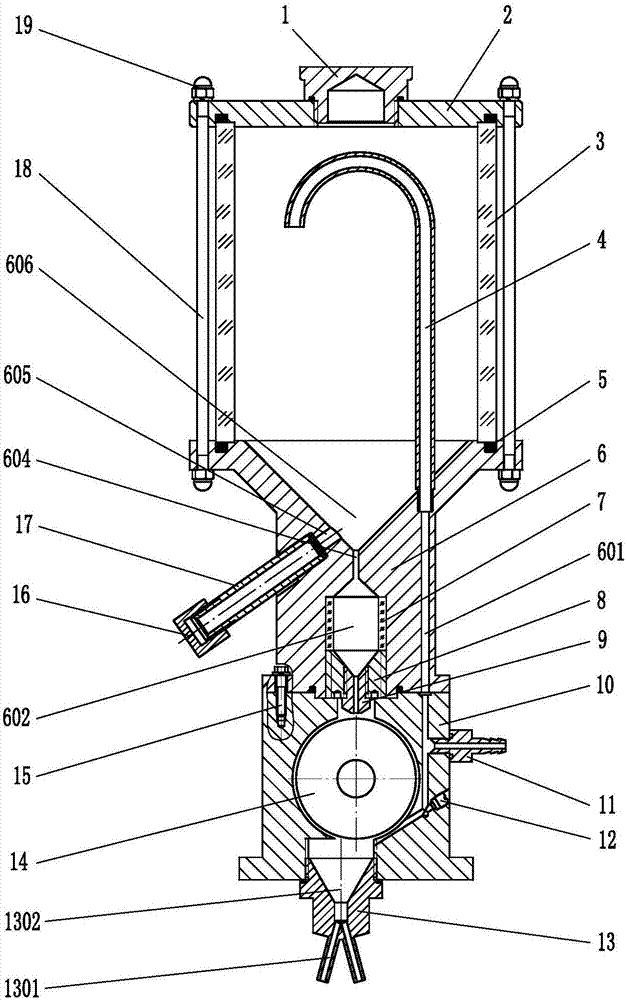

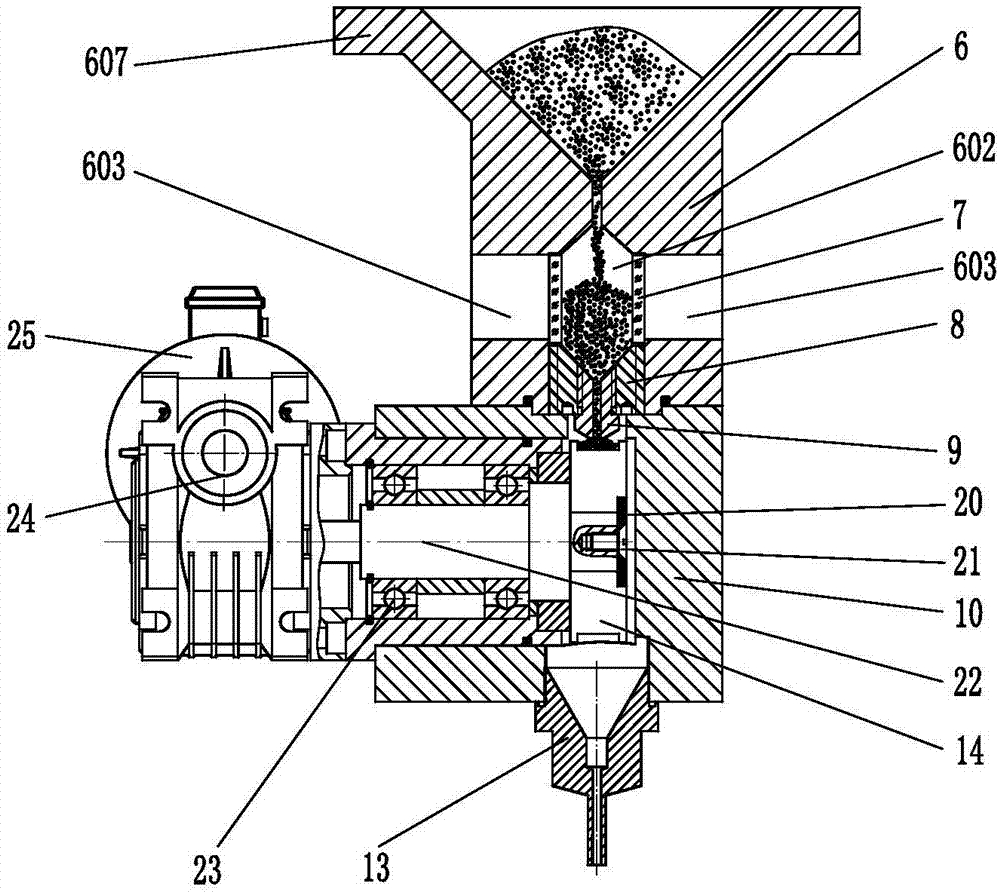

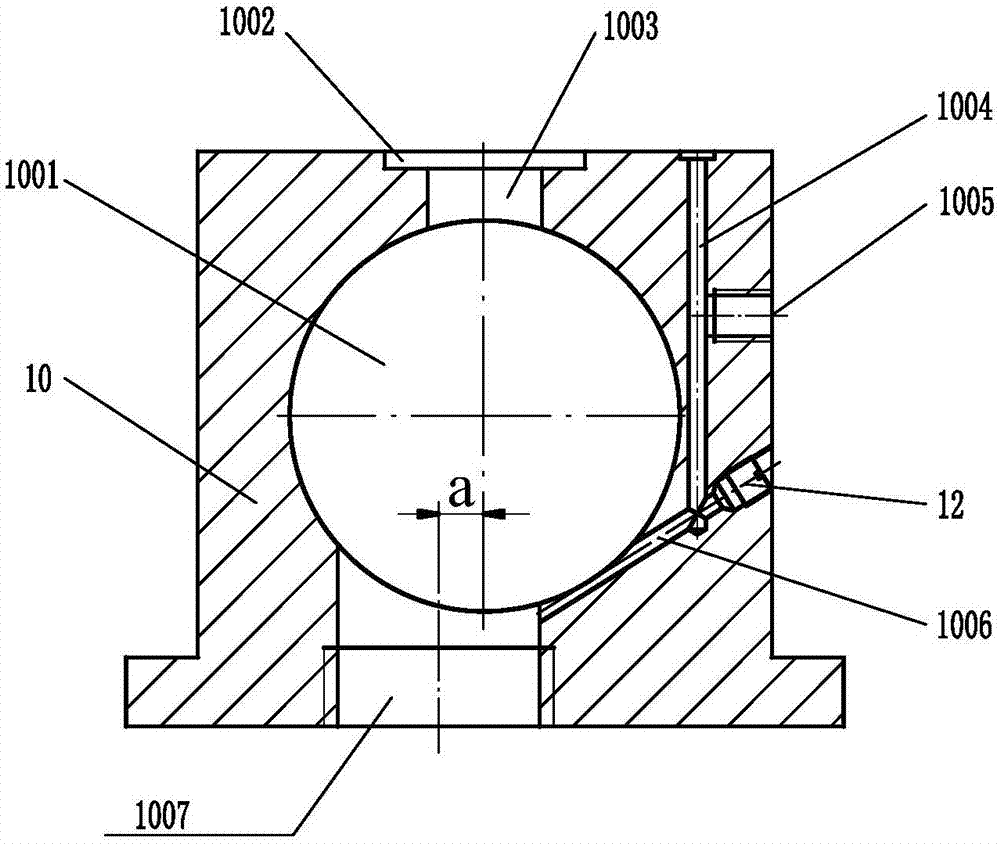

[0055] figure 1 It is the main sectional view of the visualized air-carrying roller powder feeder in one embodiment of the present invention, figure 2 It is a left cross-sectional view of the visualized air-carrying roller powder feeder in one embodiment of the present invention, image 3 It is a schematic diagram of the base of the roller feeding device in one embodiment of the present invention, Figure 4 It is a schematic view of the roller structure of the roller feeding device in one embodiment of the present invention, Figure 5 It is a schematic diagram of a leak nozzle in an embodiment of the present invention.

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the embodiment of the invention provides a visual air-carrying roller powder feeder, a powder storage cylinder 3, a funnel seat 6, and a roller feeding device arranged from top to bottom; the powder storage cylinder 3 is a transparent visible structure, through Pull rod 1...

Embodiment

[0064] Example data: the minimum diameter of the Laval nozzle of the vacuum adsorption device is 1.5mm, and the inlet and outlet diameters are 5.0mm and 2.7mm respectively. When the air supply pressure is 0.5MPa, the vacuum degree reaches 90%.

[0065] Figure 7 It is a schematic diagram of the powder feeding system in an embodiment of the present invention.

[0066] Such as Figure 7 As shown, the powder feeding system consists of three parts: powder feeder, vacuum adsorption device and gas path. The argon gas is stored in the argon cylinder 2901 after being produced. After the machine is powered on, the electromagnetic gas valve 2902 is connected, and the argon gas flows out and is connected with the tee 2903, and flows through the regulating valve 2904 and the glass rotameter 2905. The regulating valve 2904 and the glass rotameter 2905 are used to regulate and stabilize the pressure and flow of the delivered gas. Adjust the gas pressure and flow according to different n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com