A super wide field of view optical lens using only three low-cost optical materials

An optical material and optical lens technology, applied in optics, optical components, instruments, etc., can solve the problems of high cost, complex structure and high cost, and achieve the effects of easy processing, good chemical stability and low unit price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

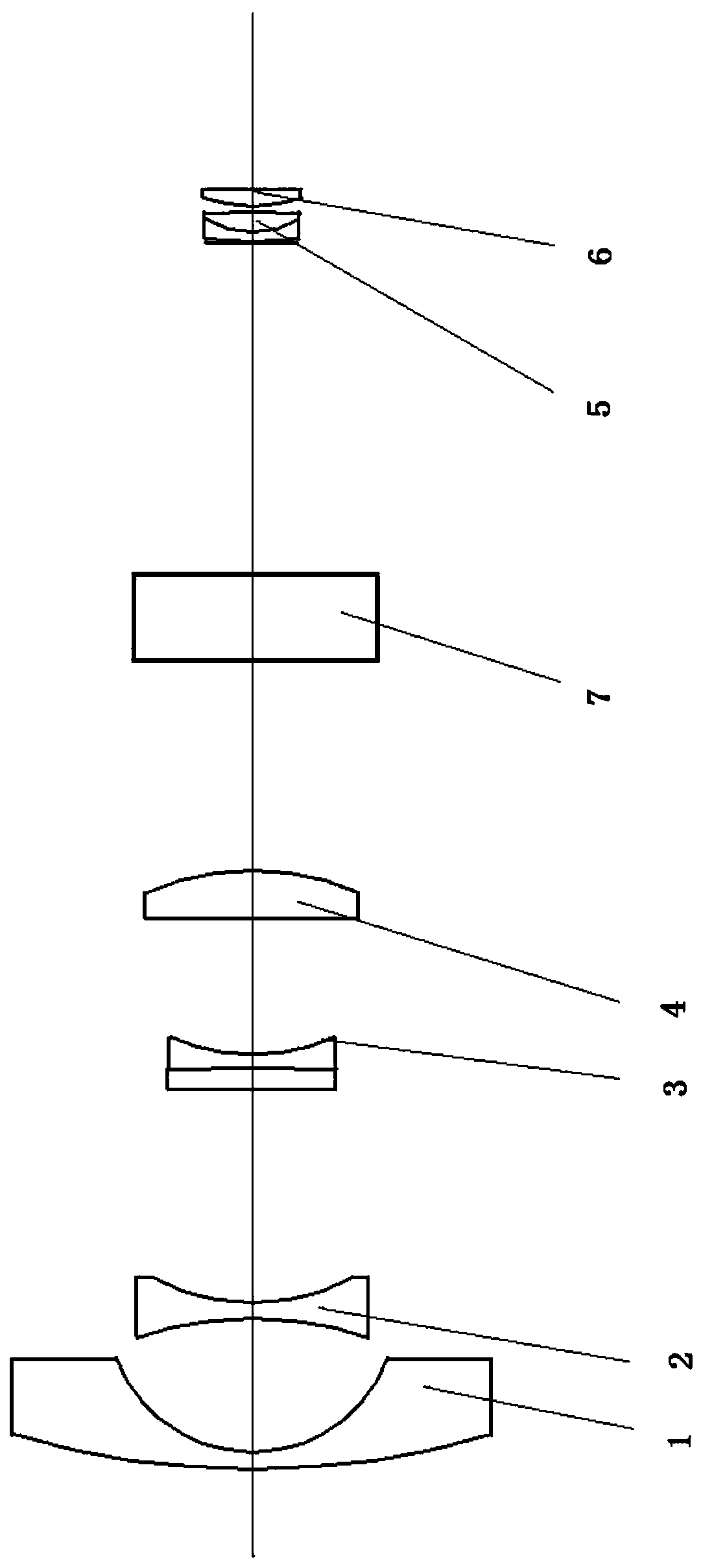

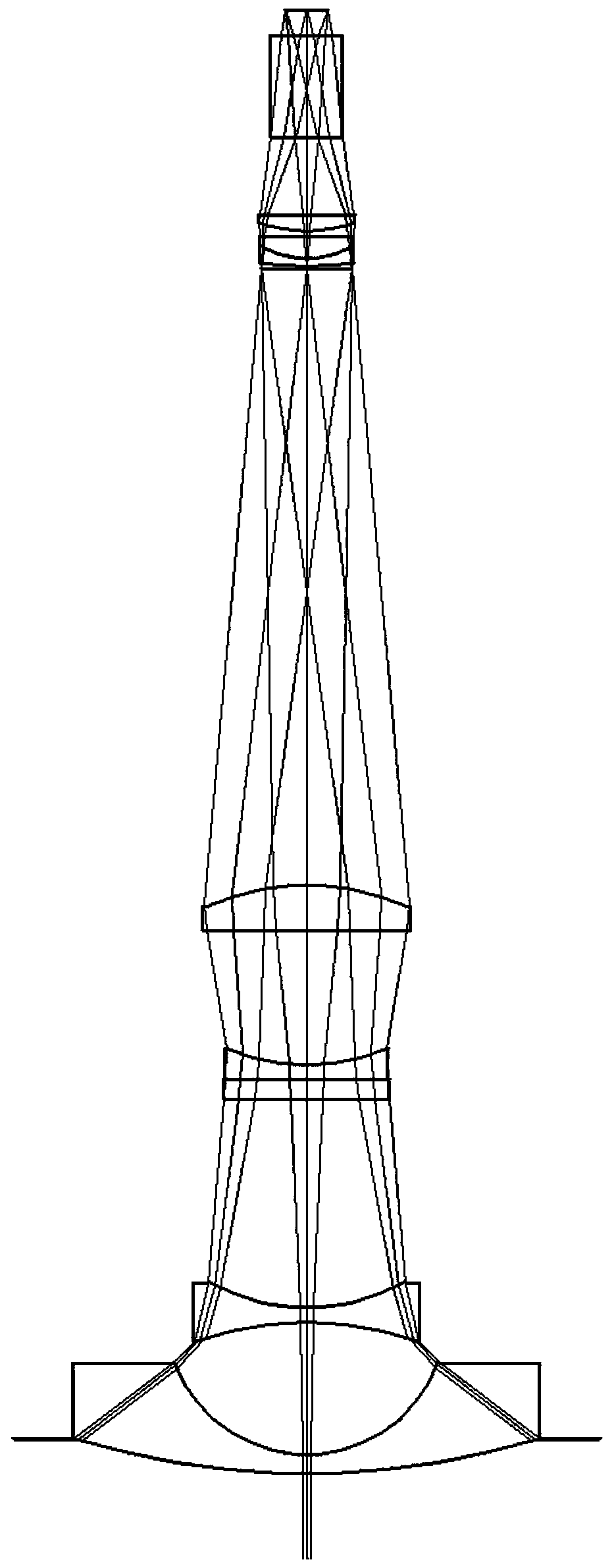

[0025] refer to Figure 1-2 , a specific embodiment of the present invention includes six mirror groups and eight lenses arranged in sequence, the first mirror group 1 is a meniscus lens with negative refractive power, the second mirror group 2 is a biconcave lens with negative refractive power, and the third mirror Group 3 is a cemented lens of a plano-convex lens and a convex-concave lens, the third lens group 3 is a negative refractive power, the fourth lens group 4 is a plano-convex lens with a positive refractive power, and the fifth lens group 5 is a cemented lens of a plano-concave lens and a convex-concave lens , the fifth lens group 5 is a plano-convex lens with positive refractive power, and the sixth lens group 6 is a plano-convex lens with positive refractive power. A diaphragm 7 is provided between the fourth mirror group 4 and the fifth mirror group 5 . The focal length of the lens structure is f=4.24mm, the relative aperture (D / f)=1 / 2, the full field of view 2w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com