Fluid contact tray particularly for the use in an offshore fractionation column

A fractionation tower and tray technology, which is applied in the directions of fractionation, separation method, distillation separation, etc., can solve problems such as unevenness, accelerated distribution, and unsatisfactory fractionation towers, and achieve improved separation efficiency, avoid uneven distribution, and high separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

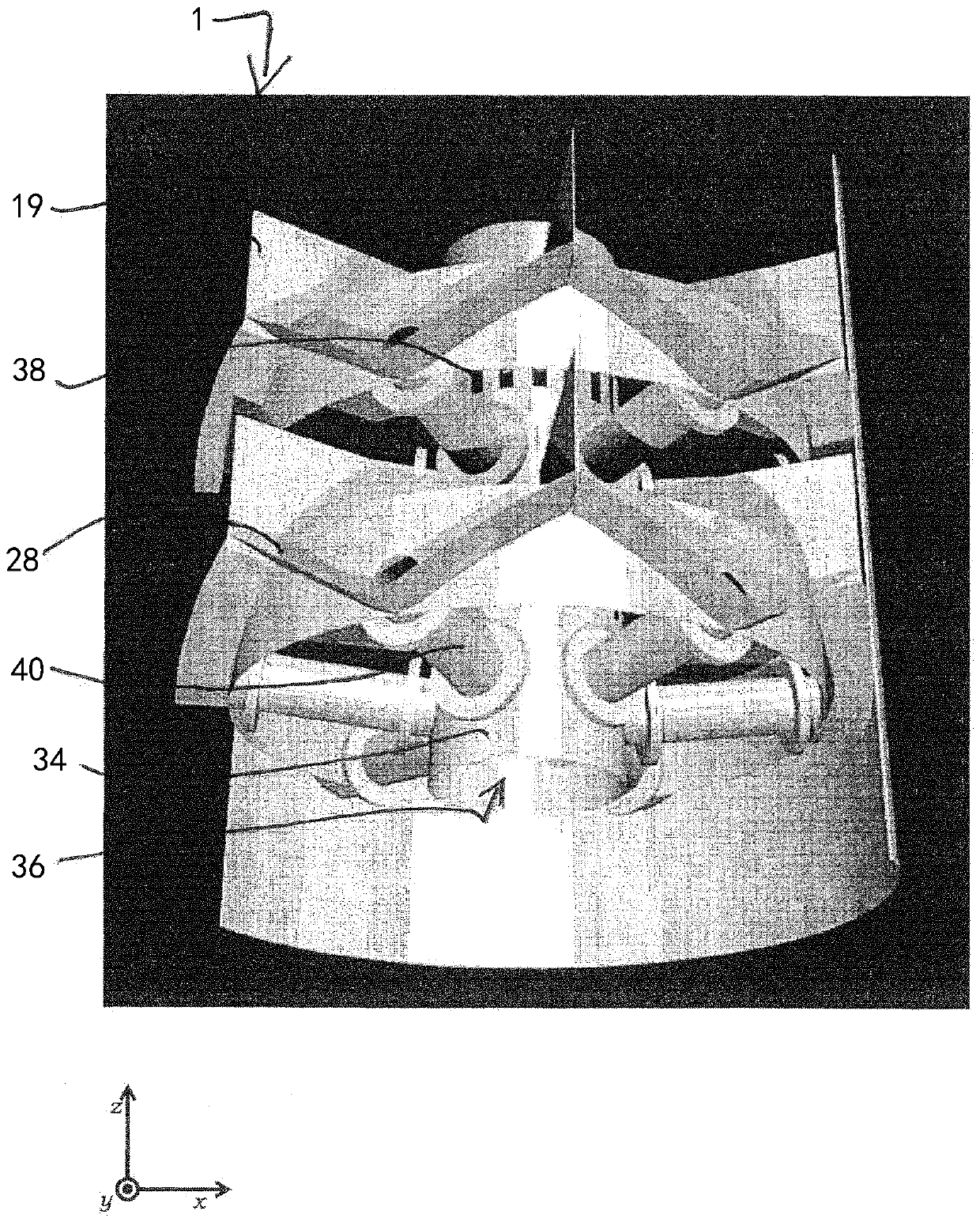

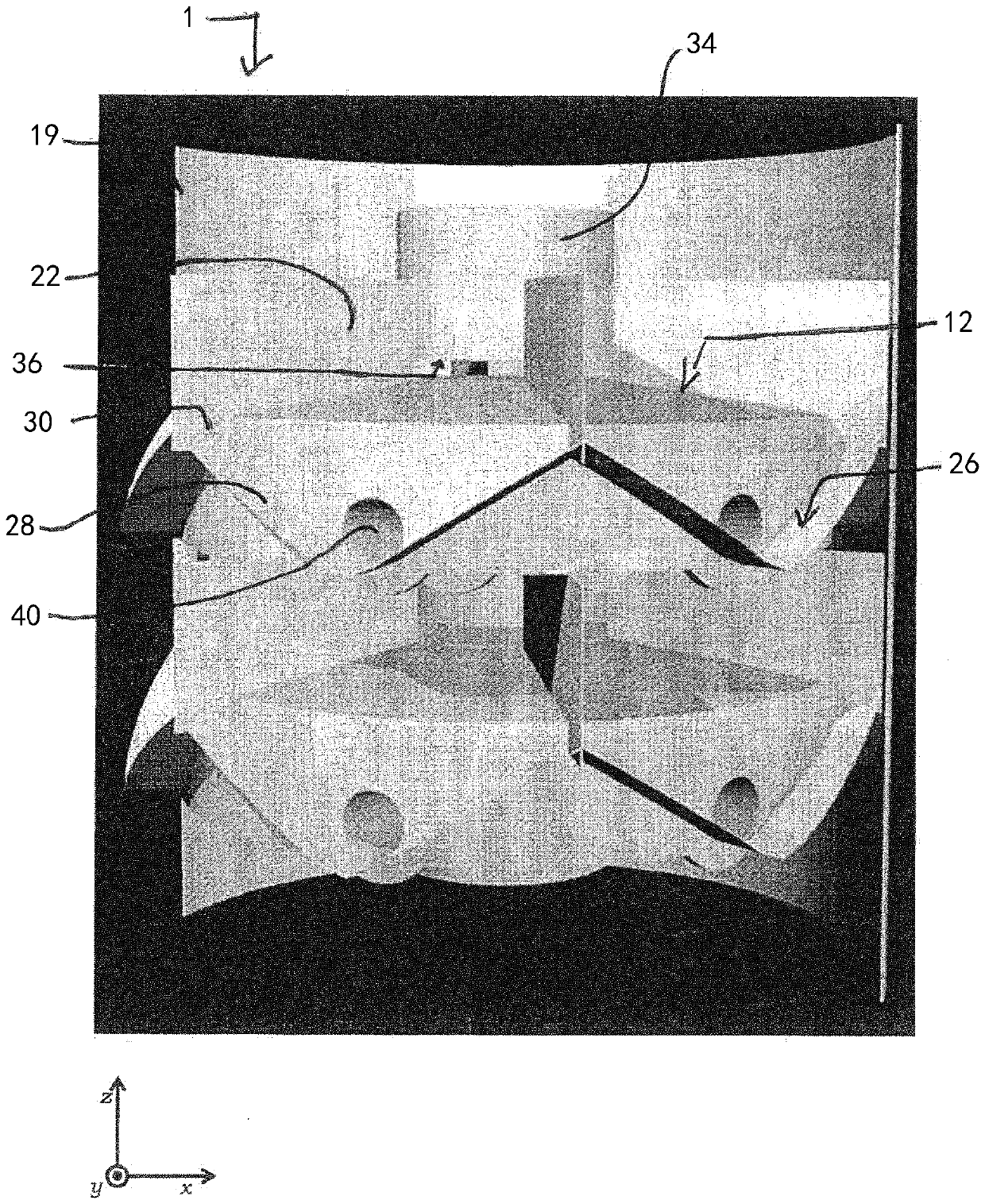

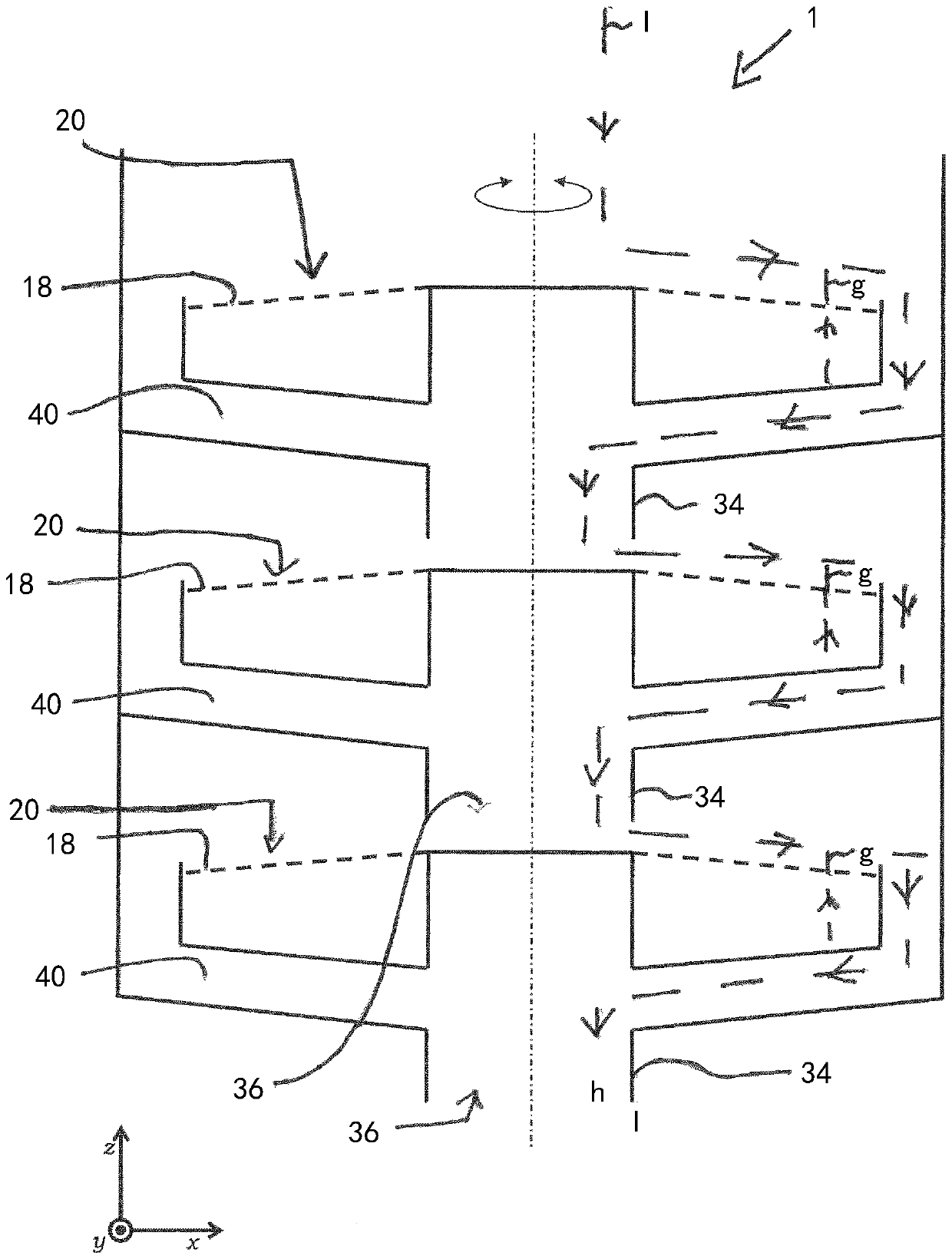

[0095] Figures 1A to 1C There is shown a fluid contact tray 10 according to an embodiment of the invention which is particularly suitable for use in fractionation columns used in offshore applications, such as those located on FLNG or FPSO vessels.

[0096] Figures 1A to 1C The fluid contact tray 10 shown has a circular shape in the horizontal plane or in the XY plane, respectively, and is therefore rotationally symmetrical with respect to the tower axis A or the height axis A, respectively.

[0097] The fluid contact tray 10 includes a tray deck 12 comprising a central portion 14 and a main portion 16, wherein the main portion 16 includes one or more apertures 18 such that the main portion 16 has an outer circular ring in top view. The surface is configured as an active mass transfer surface 20 suitable for contacting two fluids of different densities (eg radially flowing liquid (1) and rising gas g). A top view represents a view onto plane XY. Such as Figure 1A As bes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com