Long composite profile and its installation method

A composite profile and elongated technology, which is applied in the direction of load-bearing elongated structural members, building material processing, girders, etc., can solve the problem of low tear strength and achieve simple and cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

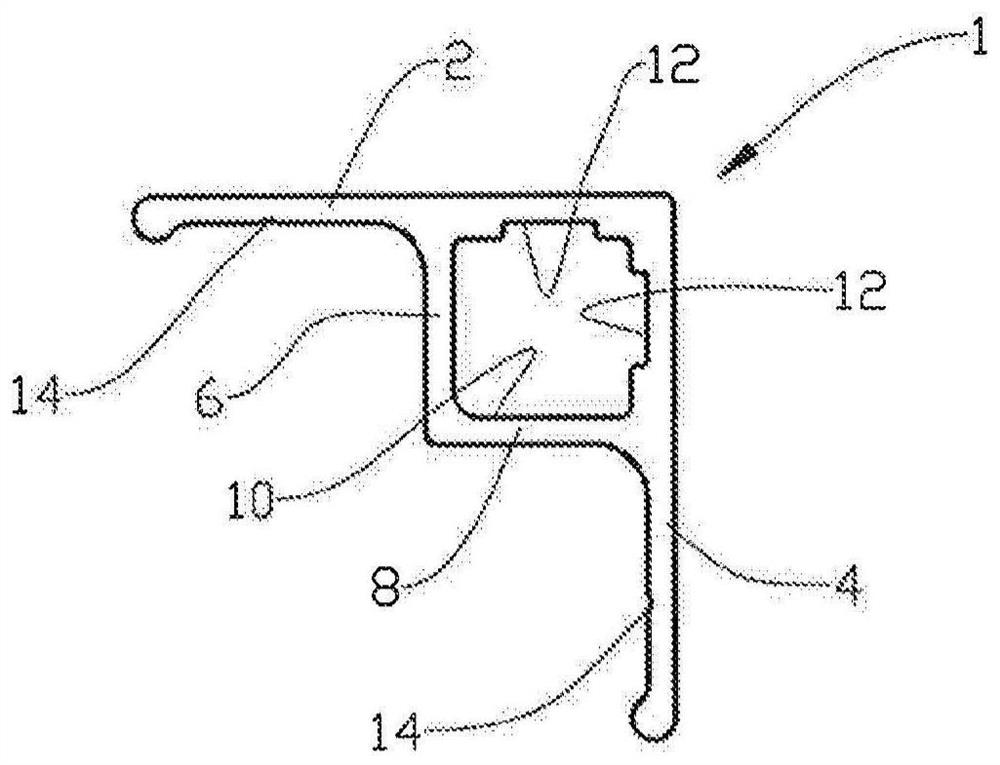

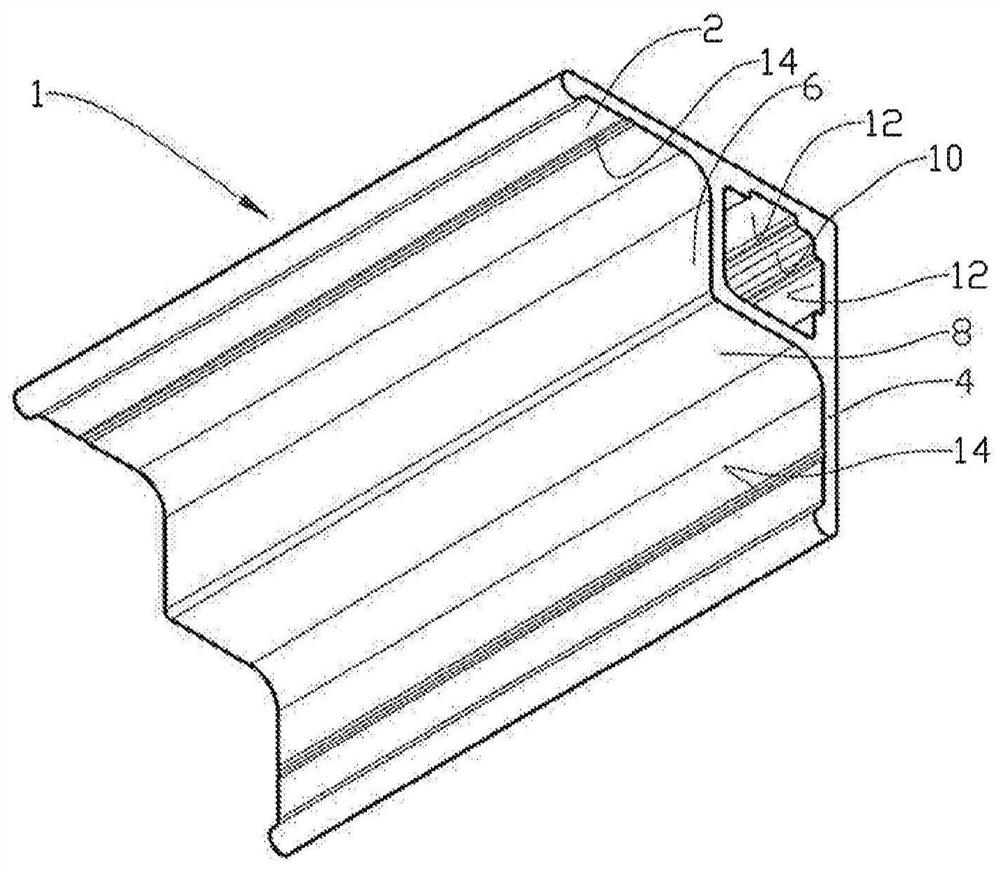

[0039] In the figures, reference numeral 1 designates a composite profile comprising a first flange 2 and a second flange 4 which together form an L-shaped profile. A first rib 6 protrudes inwardly from the first flange 2 and a second rib 8 protrudes inwardly from the second flange 4 . A part of the first flange 2 , a part of the second flange 4 , the first rib 6 and the second rib 8 form a closed channel 10 extending along the composite profile 1 .

[0040] The first rib 6 is narrower than the distal second flange 4 and the second rib 8 is narrower than the distal first flange 2 .

[0041] Inside the channel 10 , the first flange 2 and the second flange 4 are respectively formed with elongated nut bed grooves 12 . On the outside of the channel 10 , the first flange 2 and the second flange 4 are each formed with a corresponding longitudinally drilled slot 14 .

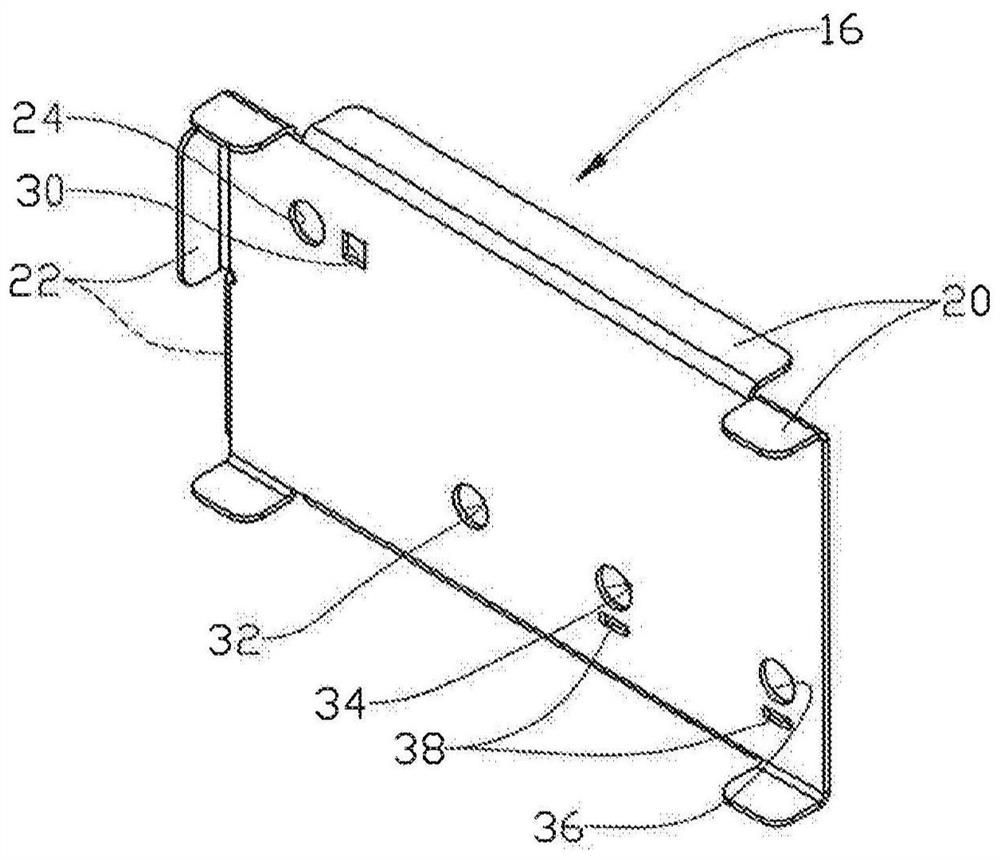

[0042] The drilling template 16 is designed to abut against the end 18 of the composite profile 1 outside the flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com