Automatic motion device for linear and transverse direction of agricultural track

A technology of automatic movement and mobile device, applied in the application, agriculture, chassis of agricultural machinery and other directions, can solve the problems of waste of field area, crop damage, large turning radius, etc., and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

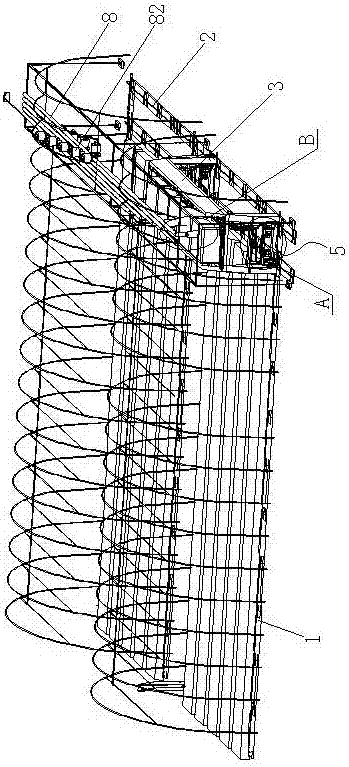

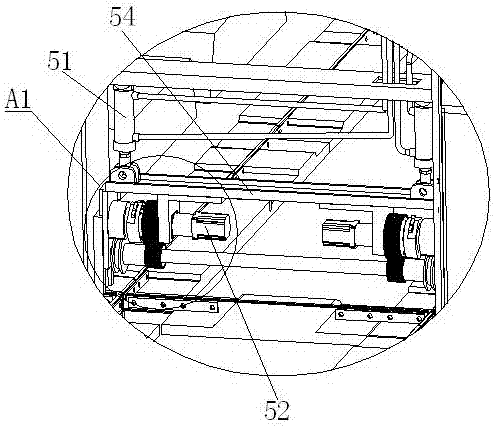

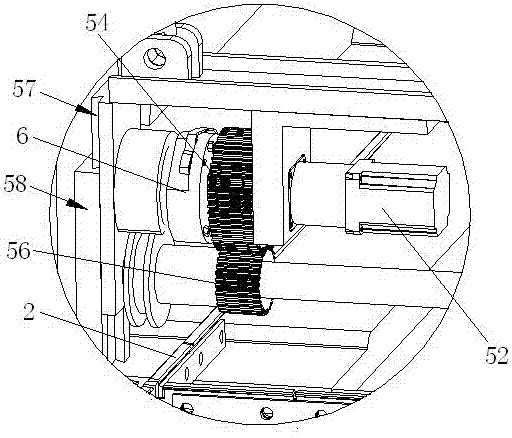

[0027] Such as Figure 1 to Figure 7 Shown is the structural representation of the present invention,

[0028] The reference signs are: straight rail 1, cross rail 2, moving device 3, straight wheel mechanism 4, straight mechanism telescopic oil cylinder 41, straight mechanism synchronous motor 42, straight mechanism roller 43, straight mechanism support 44 , straight mechanism driving bevel gear 45, straight mechanism driven gear 46, straight mechanism transition gear shaft 47, straight mechanism slider 48, straight mechanism chute 49, transverse wheel mechanism 5, transverse mechanism telescopic oil cylinder 51, Transversal mechanism synchronous motor 52, transverse mechanism roller 53, transverse mechanism support 54, transverse mechanism drive gear 55, transverse mechanism driven gear 56, transverse mechanism slider 57, transverse mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com