Cleaning device for automobile accessories

A technology for cleaning devices and auto parts, applied in the directions of dry gas arrangement, cleaning methods and utensils, cleaning methods using liquids, etc. It is not easy to clean up and other problems, so as to improve the processing effect, improve the quality of preservation and the quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

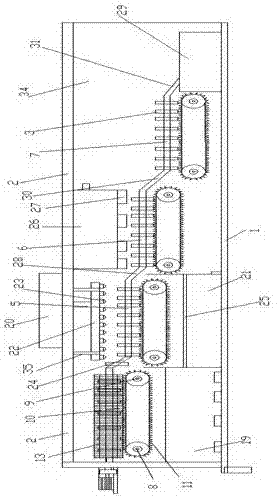

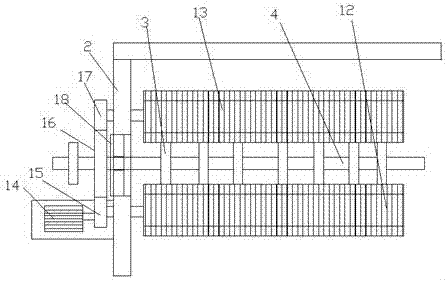

[0036] Such as Figure 1-4 As shown, the technical solution of the present invention is a cleaning device for auto parts, including a workbench 1, on which an L-shaped frame 2 is arranged, and the L-shaped frame 2 is sequentially arranged along the transmission direction of the gear 3 The dust removal mechanism, cleaning mechanism, drying mechanism and material receiving mechanism are provided with a conveying mechanism directly below the dust removing mechanism, cleaning mechanism, drying mechanism and material receiving mechanism. The structure of the transmission mechanism below the mechanism and the material receiving mechanism is the same, and the first guide rod 4 and the second guide rod 4 connected in sequence are arranged between the dust removal mechanism, the cleaning mechanism, the drying mechanism and the material receiving mechanism respectively and the transmission mechanism below each. Rod 5, third guide rod 6 and fourth guide rod 7,

[0037] Described transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com