Fully automatic press-fitting inspection line

An assembly line and fully automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as work-related injuries, high energy consumption in assembly, and hand injuries of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

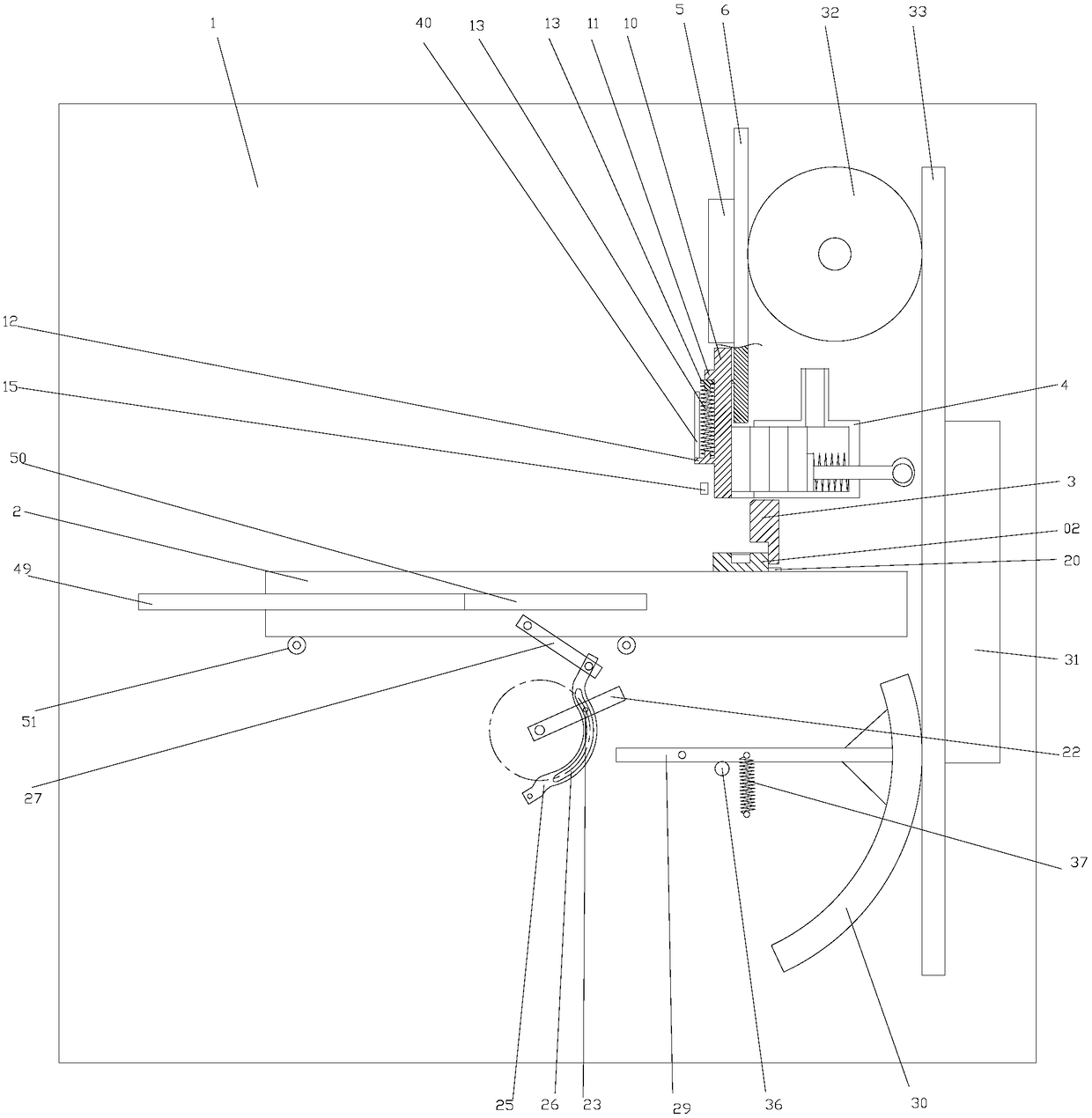

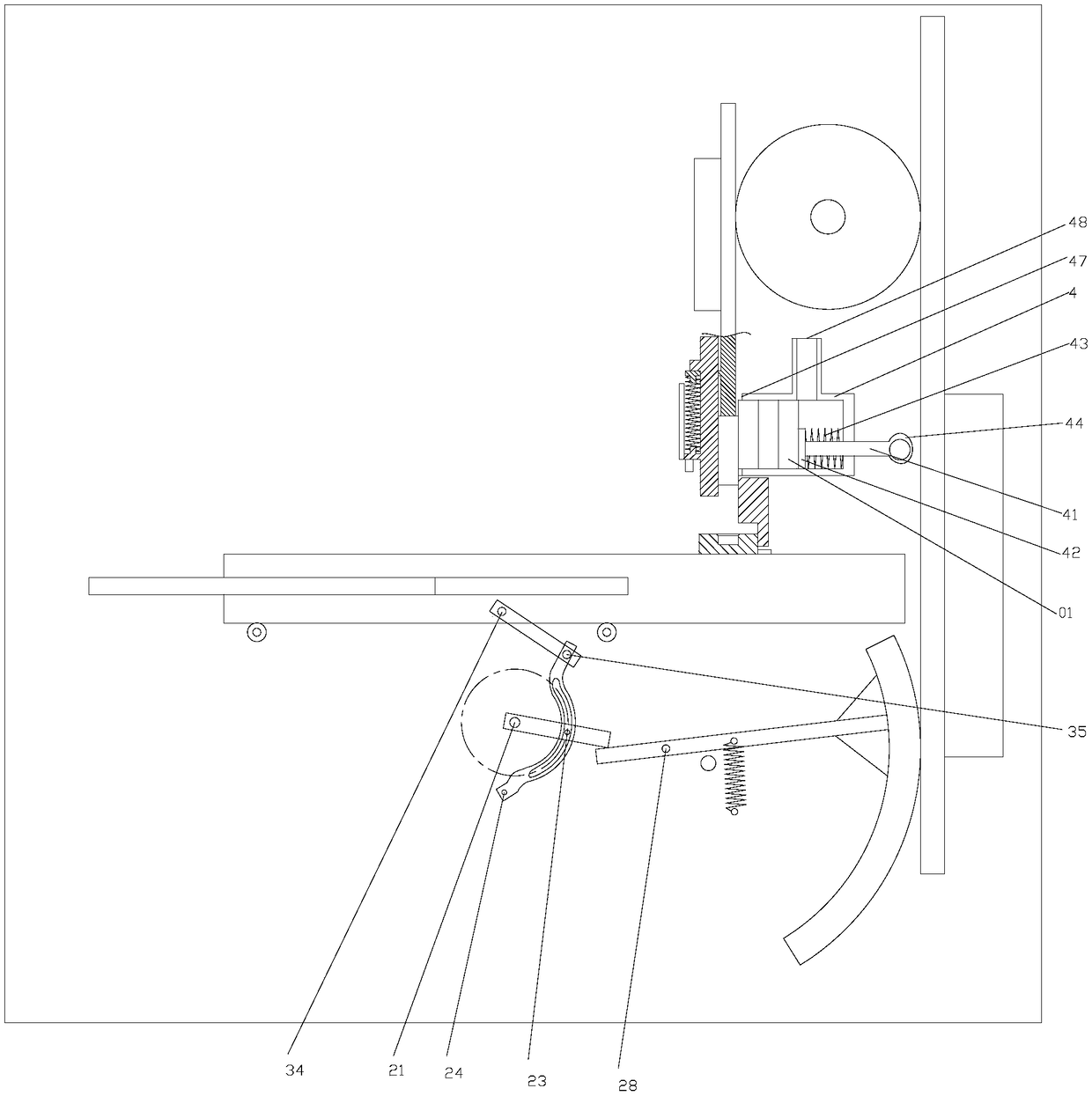

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

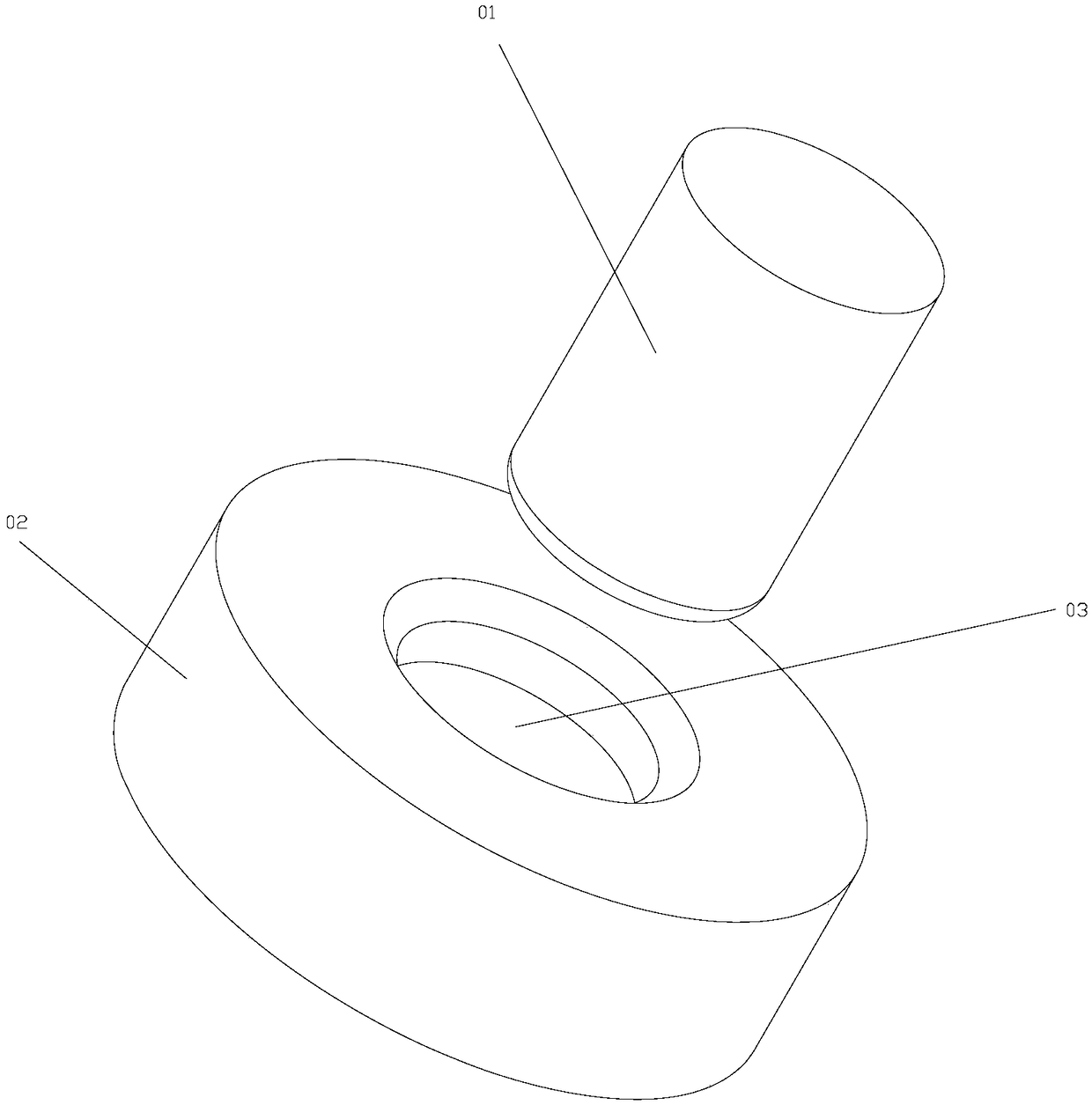

[0033] As shown in the figure, the automatic press-fitting detection line of the present invention includes a base 1, on which a sliding table 2 for placing the disc 02 is slidably connected. Open boss 20; the base 1 is provided with a stopper 3 for limiting the disc 02 in the moving direction of the slide table 2, and the base 1 is provided with a barrel 4 above the stopper 3 for accommodating the rotating shaft 01 , the rotating shaft 01 is vertically arranged in the barrel 4, the base 1 is slidably connected with the first linear rack 6 above the slide table 2 through the first guide block 5, and the lower end of the first linear rack 6 is provided with a Push the lower end of the rotating shaft 01 into the ejector rod 7 of the mounting hole 03 on the disc 02, the side wall of the first linear rack 6 is provided with a push block 8, the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com