Processing technique for bamboo sheets used for artware

A processing technology and handicraft technology, applied in wood processing equipment, sugarcane mechanical processing, manufacturing tools, etc., can solve the problems of personnel safety, mildew, and easy breakage, etc., to achieve enhanced softening effect, long-lasting anti-corrosion effect, and easy The effect of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

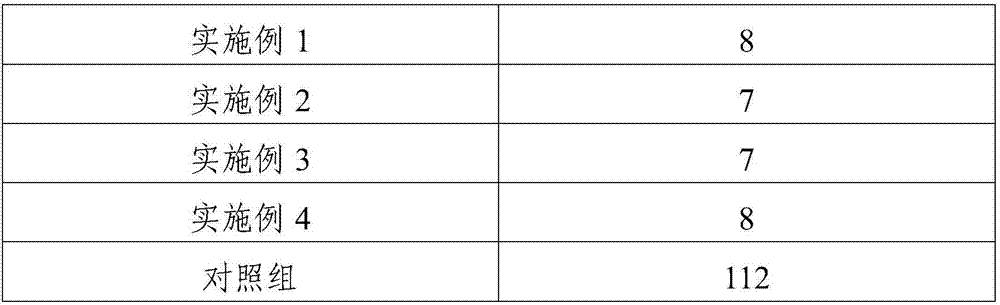

Embodiment 1

[0020] A kind of processing technology of bamboo chip for handicraft, comprises the following steps:

[0021] (1) Wash the bamboo tube, open the slices, soak in water at 65°C for 4 hours, and change the water every hour after soaking;

[0022] (2) Put the soaked bamboo slices in step (1) into a vacuum chamber to evacuate to 0.007Mpa, hold the pressure for 20min, then feed 120°C, 0.2Mpa high-temperature and high-pressure steam into the vacuum chamber, and heat-preserve and hold-pressure for 16h;

[0023] (3) Put the bamboo slices treated in step (2) into the softening solution with 6 times the weight of the bamboo slices and soak for 8 hours, clean them with clear water, then transfer them to the bactericidal antiseptic solution with 10 times the weight of the bamboo slices and soak them at 60°C 4h, during the soaking process, continuously feed a mixed gas of oxygen, hydrogen and hydrogen chloride into the sterilizing antiseptic solution, and the oxygen, hydrogen and hydrogen c...

Embodiment 2

[0030] A kind of processing technology of bamboo chip for handicraft, comprises the following steps:

[0031] (1) Wash the bamboo tube, open the slices, soak in 70°C water for 5 hours, and change the water every 1 hour;

[0032] (2) put the bamboo chips soaked in step (1) into a vacuum chamber to evacuate to 0.008Mpa, hold the pressure for 20min, then feed 120°C, 0.2Mpa high-temperature and high-pressure steam into the vacuum chamber, and heat-preserve and hold-pressure for 14h;

[0033] (3) Put the bamboo slices treated in step (2) into softening solution with 7 times the weight of bamboo slices and soak for 7 hours, rinse with clear water, then transfer to sterilizing and antiseptic solution with 11 times the weight of bamboo slices and soak at 65°C 3h, during the soaking process, continuously feed the mixed gas of oxygen, hydrogen and hydrogen chloride into the sterilizing and antiseptic solution, and the oxygen, hydrogen and hydrogen chloride are mixed according to the vol...

Embodiment 3

[0040] A kind of processing technology of bamboo chip for handicraft, comprises the following steps:

[0041] (1) Wash the bamboo tube, open the slices, soak in water at 75°C for 4 hours, and change the water every hour after soaking;

[0042] (2) Put the soaked bamboo slices in step (1) into a vacuum chamber to evacuate to 0.009Mpa, hold the pressure for 20min, then feed 120°C, 0.2Mpa high-temperature and high-pressure steam into the vacuum chamber, and heat-preserve and hold-pressure for 12h;

[0043] (3) Put the bamboo slices treated in step (2) into the softening solution with 8 times the weight of the bamboo slices and soak for 6 hours, clean them with clear water, then transfer them to the sterilizing and antiseptic solution with 12 times the weight of the bamboo slices and soak them at 60°C 5h, continuously feed the mixed gas of oxygen, hydrogen and hydrogen chloride into the sterilizing and antiseptic liquid during the soaking process, and the oxygen, hydrogen and hydr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap