Precision installation on-track mechanical arm device

A technology for installing rails and robotic arms, applied in the direction of mechanical conveyors, conveyors, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

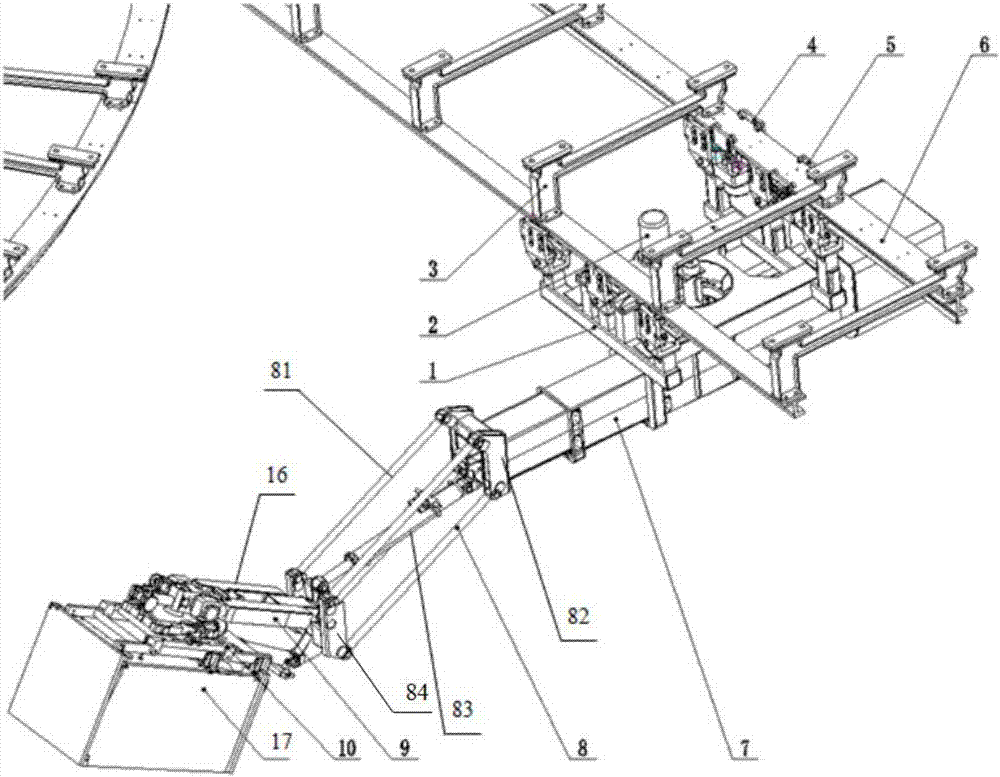

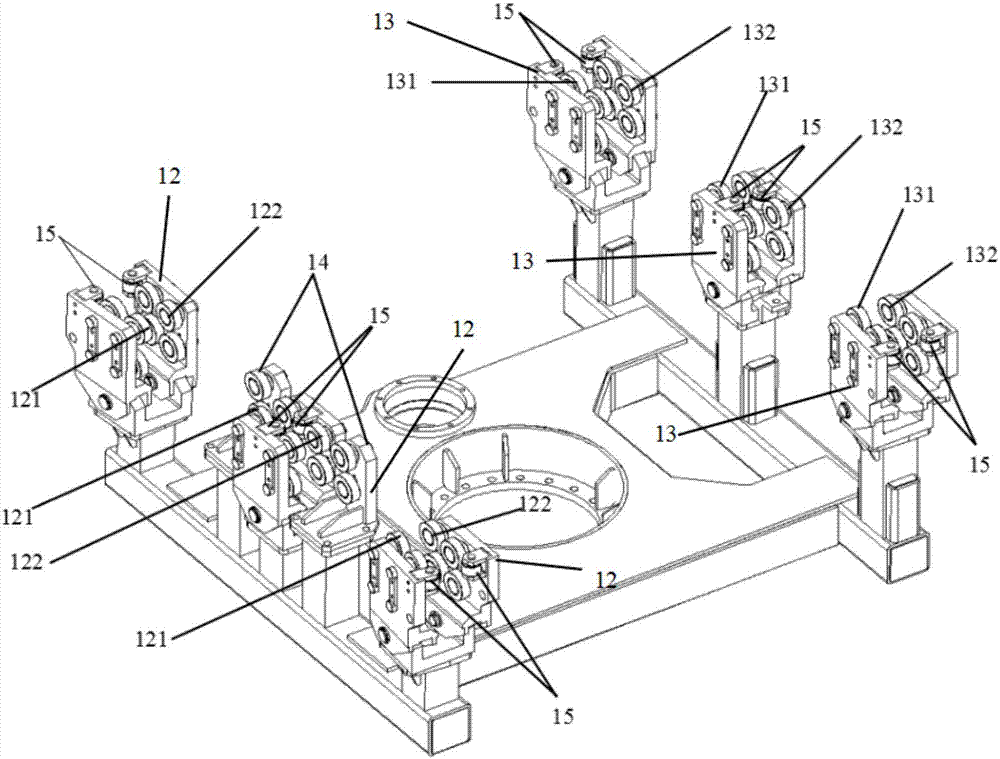

[0034] combine Figure 1-8Describe this embodiment, a precision mounting rail mechanical arm device of this embodiment, the mechanical arm device includes a trailer 1, a slewing mechanism 2, a traction trolley 4, a track 6, a telescopic mechanism 7, a translation mechanism 8 and a manipulator 16; The trailer 1 is suspended on the track 6 by the trailer wheel set mechanism; the traction trolley 4 is suspended on the track 6 by the traction trolley wheel mechanism, and is fixedly connected with the trailer 1 for driving the trailer 1 to travel on the track 6; The bottom of the trailer 1 is fixed with a rotary mechanism 2; the bottom of the rotary mechanism 2 is fixed with a telescopic mechanism 7, which is used to drive the telescopic mechanism 7 to rotate 360° in the horizontal plane; the telescopic end of the telescopic mechanism 7 and the translation mechanism 8 connected to drive the translation mechanism 8 to reciprocate in the horizontal direction; the translation end of t...

Embodiment approach 2

[0043] On the basis of Embodiment 1, this embodiment adds technical features: the mechanical arm device also includes a power-taking trolley 5; Suspended on the track 6, and the power-taking trolley 5 is fixedly connected with the trailer 1. The added technical features of this embodiment achieve the effect of providing power for the entire mechanical arm device.

[0044] Such as figure 1 As shown, in this embodiment, the power-taking trolley 5 is suspended on the track 6 through a set of wheels, the power-taking trolley 5 is connected with the trailer through a pin shaft, and the power-taking trolley 5 and the trailer 1 are driven on the track 6 by the traction trolley 4 together. Traveling; start the hydraulic system and the electric control system after the power-taking trolley 5 gets power, and provide power for the whole system.

Embodiment approach 3

[0046] On the basis of the second embodiment, this embodiment adds technical features: the track 6 is also provided with a power transmission ring; the power transmission ring is electrically connected to the power-taking terminal of the power-taking trolley 5 to provide power for the mechanical arm device . The added technical features of this embodiment achieve the effect of providing power for the robotic arm device.

[0047] In this embodiment, the power transmission ring may be an aluminum power transmission ring.

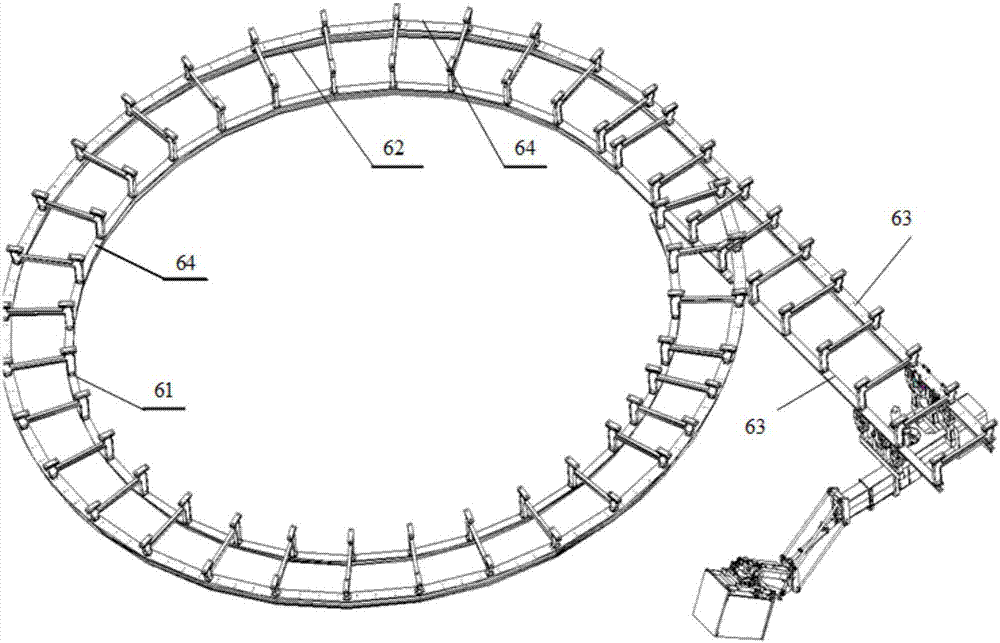

[0048] In this embodiment, the electric power required by the electrical system of the manipulator is taken by the electric trolley 5, and two continuous aluminum power transmission rings can be arranged on the lower side of the upper wing plate of the outer rail 62 of the track 6, and the power transmission ring is at the end of the straight rail. The whole part is connected to the laboratory power supply, and the power-taking trolley 5 is equipped with a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com