Reflective sheet, manufacturing method thereof, and backlight module

A manufacturing method and a technology for a reflective sheet are applied in the fields of reflective sheets and backlight modules, which can solve the problems of increasing the thickness of the reflective sheet and the entire display device, which are disadvantageous to the thinning of the display device, and achieve the effect of reducing the thickness and improving the display color gamut.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

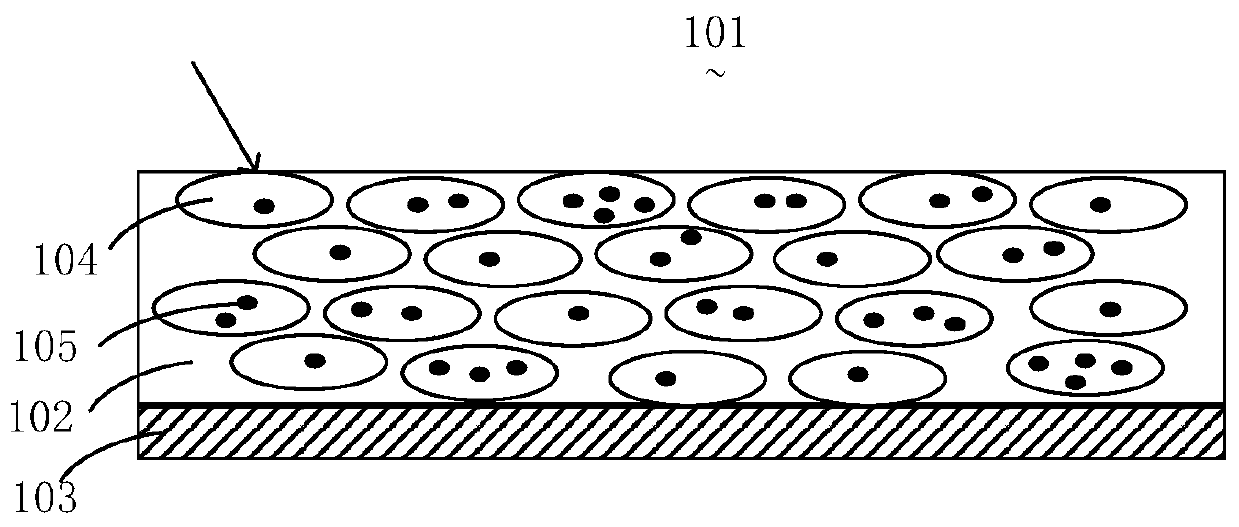

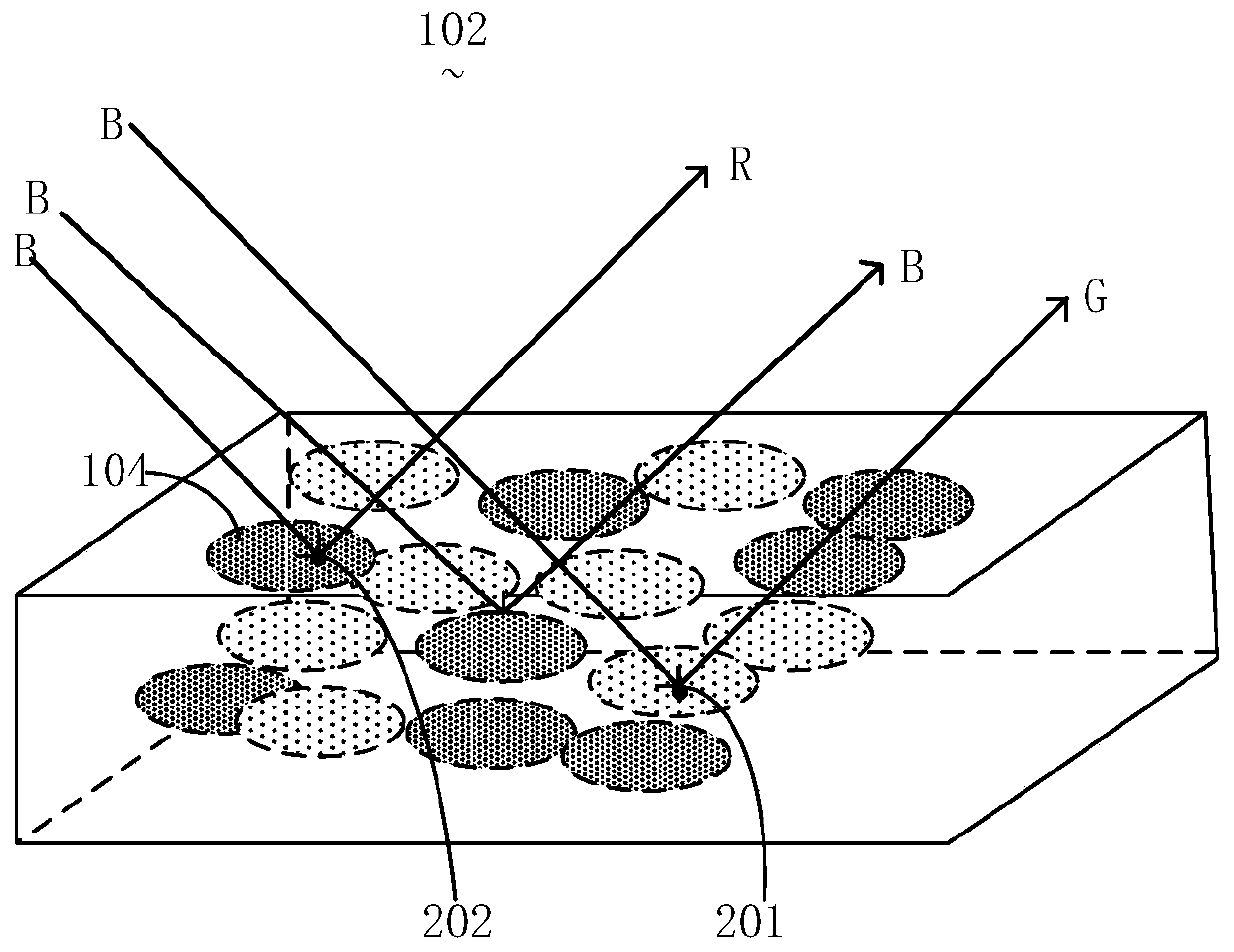

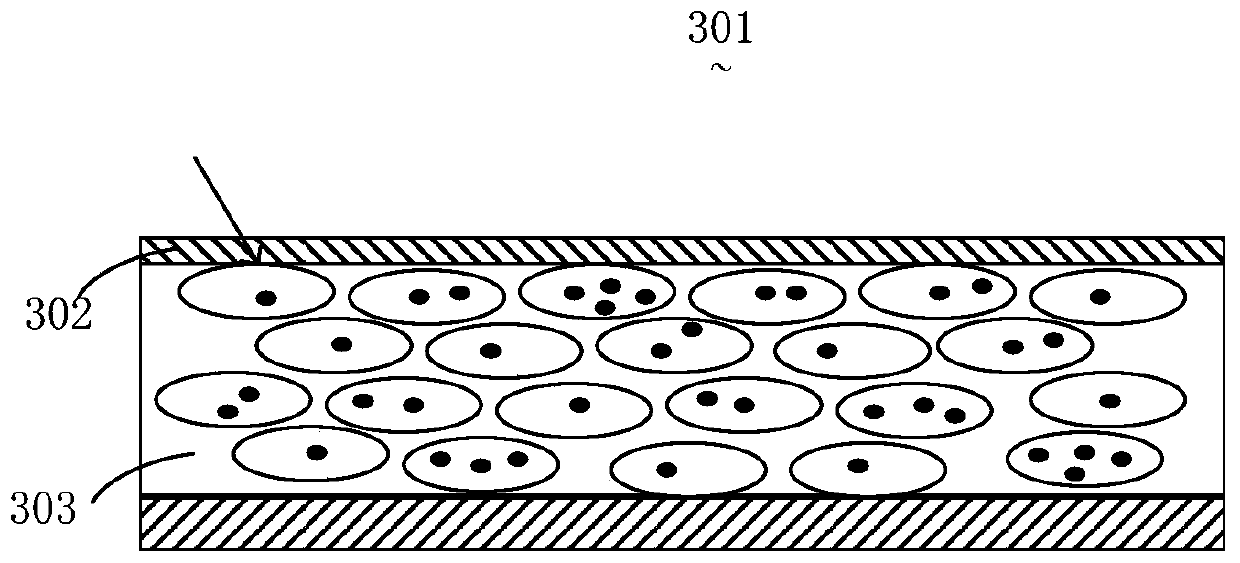

[0016] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the reflective sheet of the present invention. The reflective sheet 101 of this embodiment is used to reflect the incident light irradiated on the reflective sheet 101; the reflective sheet 101 includes at least an air bubble layer 102 and a first film layer 103, and the first film layer 103 is arranged on the non-light-incident side of the air bubble layer 102 surface for diffusely reflecting incident light, wherein the bubble layer 102 includes a plurality of embedded bubbles 104 and quantum dots 105, and the quantum dots 105 generate light with a wavelength different from that of the incident light when excited by the incident light.

[0017] The thickness dimension of the reflective sheet 101 is negligible relative to the surface size of the light-incident side. Therefore, the light-incident side of the reflective sheet 101 in this embodiment is its light-exit side, and the light-incid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com