OLED display device and manufacturing method thereof, color filter substrate and manufacturing method thereof

A technology of a display device and a manufacturing method, which is applied to chemical instruments and methods, semiconductor/solid-state device manufacturing, instruments, etc., can solve the problems of low display brightness of OLED display devices, increased cost of OLED display devices, and expensive quantum dot materials, etc. , to achieve the effect of low price, improved stability and high luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

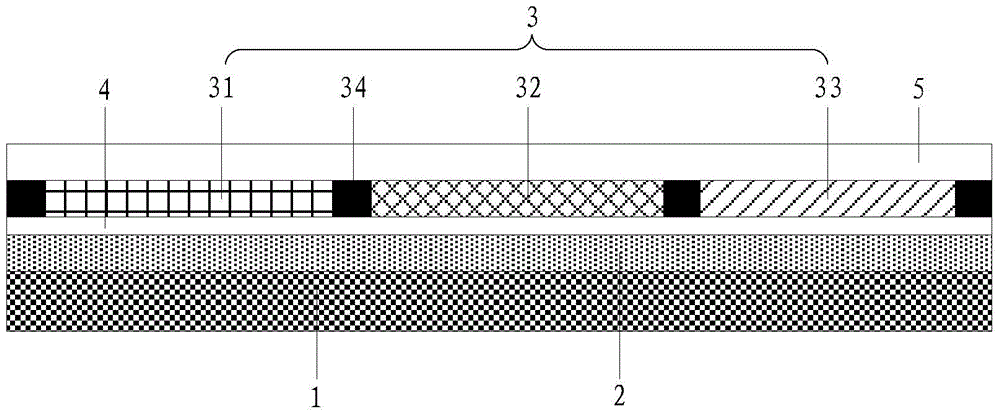

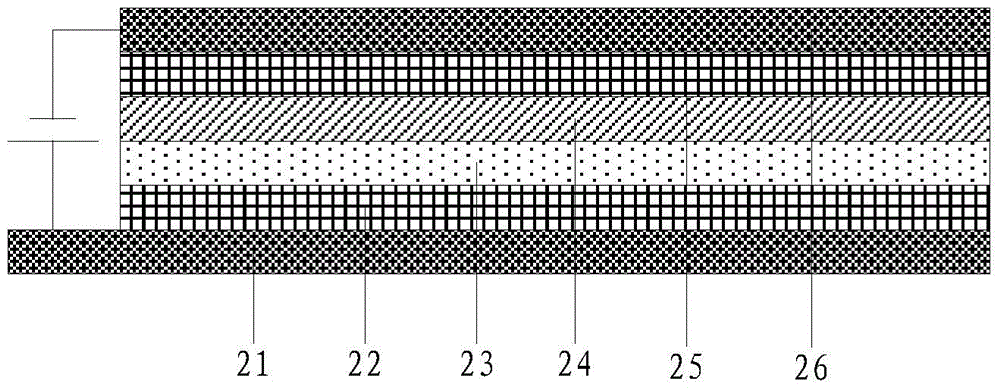

[0038] This embodiment provides an OLED display device, such as figure 1 As shown, the OLED display device includes: a TFT array substrate 1; a light emitting structure layer 2 disposed on the TFT array substrate 1, the light emitted by the light emitting structure layer 2 is infrared light; a light conversion layer located on the light emitting structure layer 2 3. The light conversion layer 3 includes a plurality of pixel areas, and each pixel area is provided with at least three light conversion units of red light, green light and blue light.

[0039] Among them, the red light conversion unit 31 is formed by an up-conversion luminescent material that emits red light after being excited by infrared light; the green light conversion unit 32 is formed by an up-conversion luminescent material that emits green light after being excited by infrared light; the blue light conversion unit 33 is formed by an up-conversion luminescent material that emits blue light after being excited...

Embodiment 2

[0051] This embodiment provides a method for manufacturing an OLED display device, the method comprising the following steps:

[0052] Step S1: if Figure 3a As shown, a TFT array substrate 1 was fabricated.

[0053] Step S2: if Figure 3b As shown, a light emitting structure layer 2 is formed on a TFT array substrate 1, and the light emitted by the light emitting structure layer 2 is infrared light.

[0054] Step S3: forming a light conversion layer, the light conversion layer is located on the light-emitting structure layer, the light conversion layer includes a plurality of pixel areas, and at least three light conversion units of red light, green light and blue light are arranged in each pixel area. Among them, the red light conversion unit is formed by an up-conversion luminescent material that emits red light after being excited by infrared light; the green light conversion unit is formed by an up-conversion luminescent material that emits green light after being excit...

Embodiment 3

[0067] This embodiment provides a color filter substrate, such as Figure 3e As shown, the color filter substrate includes: a base substrate 5; a light conversion layer 3 disposed on the base substrate 5, the light conversion layer 3 includes a plurality of pixel regions, each pixel region is provided with at least red light, green Three light conversion units for light and blue light. Among them, the red light conversion unit 31 is formed by an up-conversion luminescent material that emits red light after being excited by infrared light; the green light conversion unit 32 is formed by an up-conversion luminescent material that emits green light after being excited by infrared light; the blue light conversion unit 33 is formed by an up-conversion luminescent material that emits blue light after being excited by infrared light.

[0068] In the above-mentioned color filter substrate, different up-conversion light-emitting materials are used to form red light, green light and bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com