High-energy-efficiency air source heat pump

An air source heat pump, high energy efficiency technology, applied in the field of heat pump, can solve problems such as bonding, evaporator not working normally, affecting refrigerant transmission, etc., to achieve the effect of improving safety, improving strength and deformation resistance, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

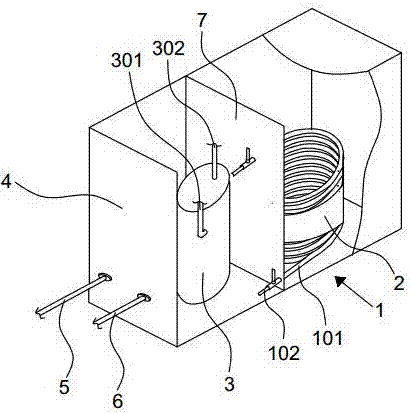

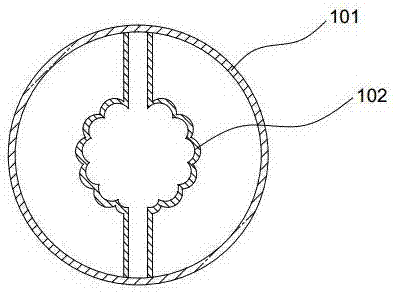

[0022] Such as Figure 1~5 As shown, the high-energy-efficiency air source heat pump includes a casing 4, an evaporator 1 and a compressor 3 arranged at the inner bottom of the casing 4, the compressor 3 is provided with a compressor inlet 301 and a compressor outlet 302, and the side wall of the casing 4 The lower end is provided with a total refrigerant inlet 5 and a total refrigerant outlet 6, the total refrigerant pipe inlet 5 is connected to the evaporator 1, the evaporator 1 is connected to the compressor 3, the compressor 3 is connected to the total refrigerant pipe outlet 6, the evaporator 1 and the compressor 3 is provided with a heat insulation board 7, the edge of the heat insulation board 7 is connected with the inner wall of the shell 4, and a heat insulation board 7 is provided between the evaporator 1 and the compressor 3, which can effectively prevent the heat emitted by the evaporator 1 from affecting the compressor. 3, to improve the service life of the compr...

Embodiment 2

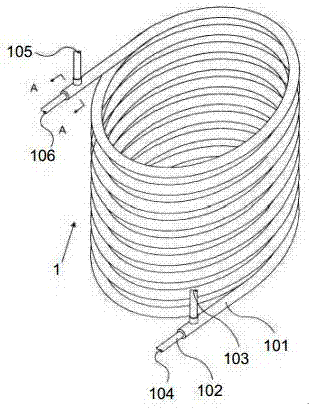

[0032] Such as Figure 1~5 As shown, in an air source heat pump with high energy efficiency, in actual operation, the total refrigerant inlet 5 is connected to the first refrigerant pipe inlet 105, the first refrigerant pipe outlet 103 is connected to the second refrigerant pipe inlet 104, and the second refrigerant pipe outlet 106 and The compressor inlet 301 is connected, the compressor outlet 302 is connected with the main refrigerant pipe outlet 6, the refrigerant enters from the main refrigerant inlet 5, and when working, the compressor 3 is turned on to make it work, and the refrigerant flows into the evaporator 1 from the main refrigerant pipe inlet 5 The first refrigerant pipe inlet 105 of the first refrigerant pipe flows into the second refrigerant pipe inlet 104 from the first refrigerant pipe outlet 103, and flows into the compressor inlet 301 from the second refrigerant pipe outlet 106. The compressor 3 converts the refrigerant from low temperature and low pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com