Reinforcing process of concrete circular tower column

A technology of concrete and tower columns, which is applied in the treatment of towers and building materials, building maintenance, etc., can solve the problems of difficult application of cross-section reinforcement method and large consumption of steel materials, and achieve improved structural mechanical properties, good fire resistance, and shrinkage crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is further described.

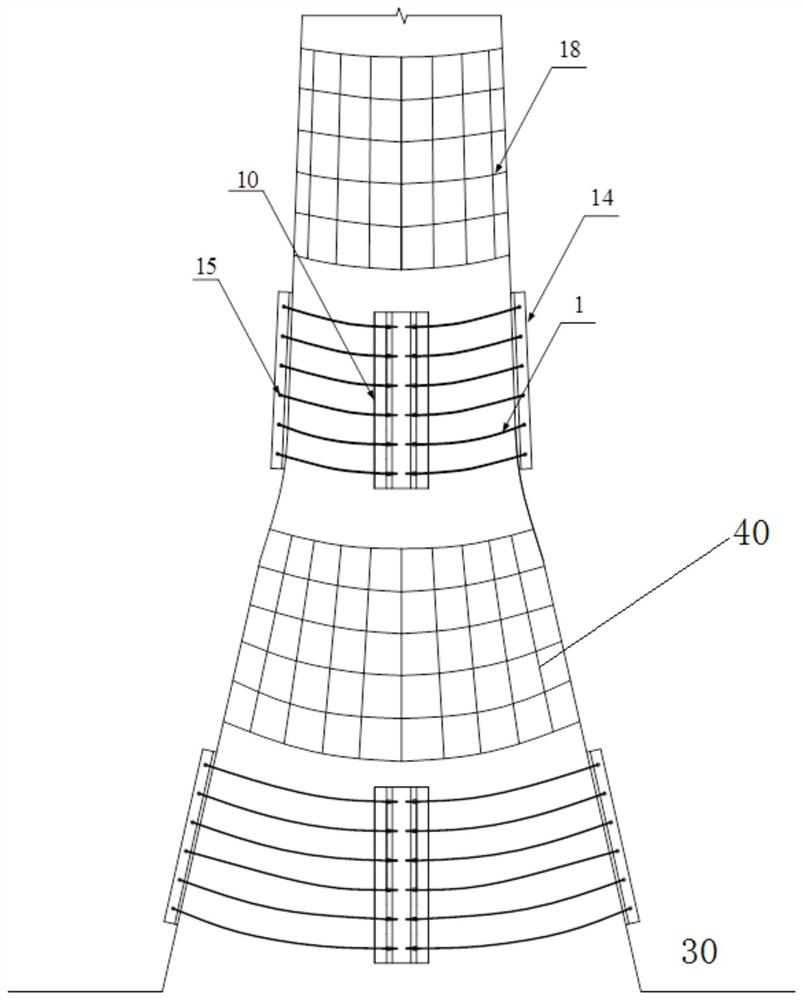

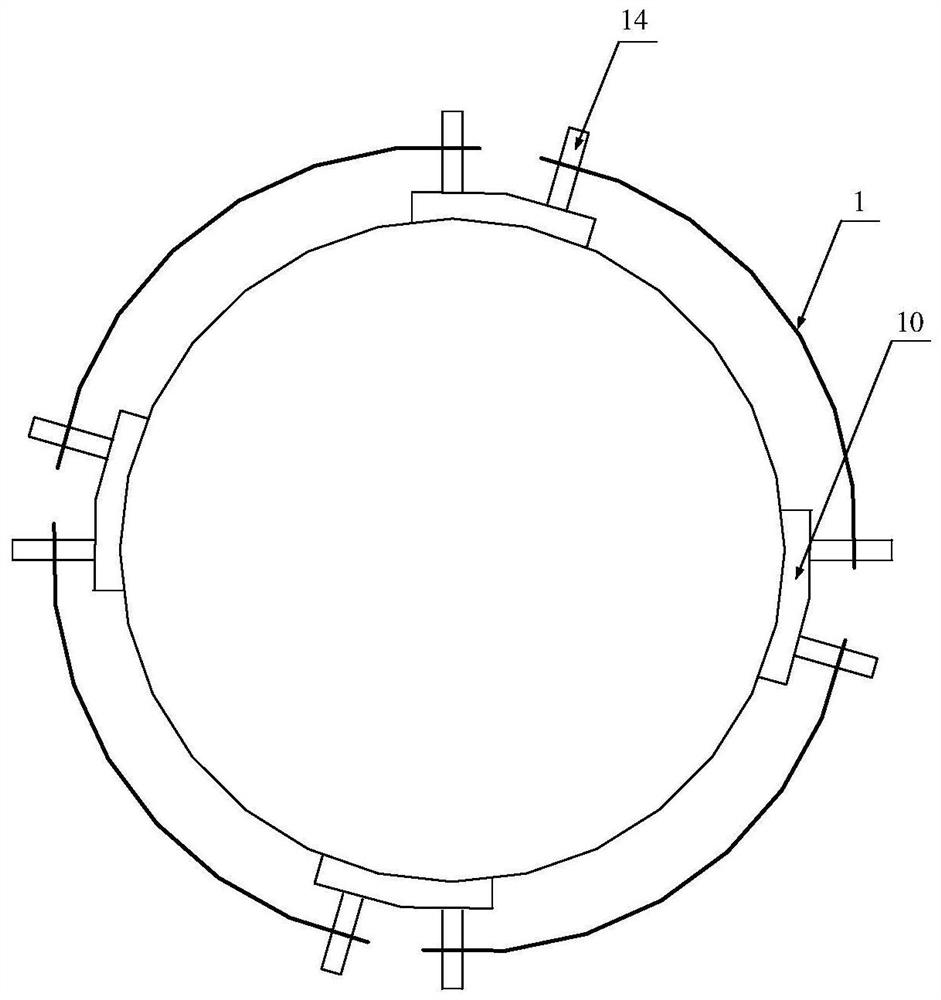

[0039] Such as figure 1 shown. The reinforcement process of the concrete tower column involved in the present invention comprehensively adopts the prestressed reinforcement method and the FRP grid reinforcement method, specifically: (1) for severe cracking areas, adopt prestressed steel wire rope reinforcement (30); (2) For the slightly cracked area of the concrete on the surface of the tower column, the FRP mesh is used to reinforce (40).

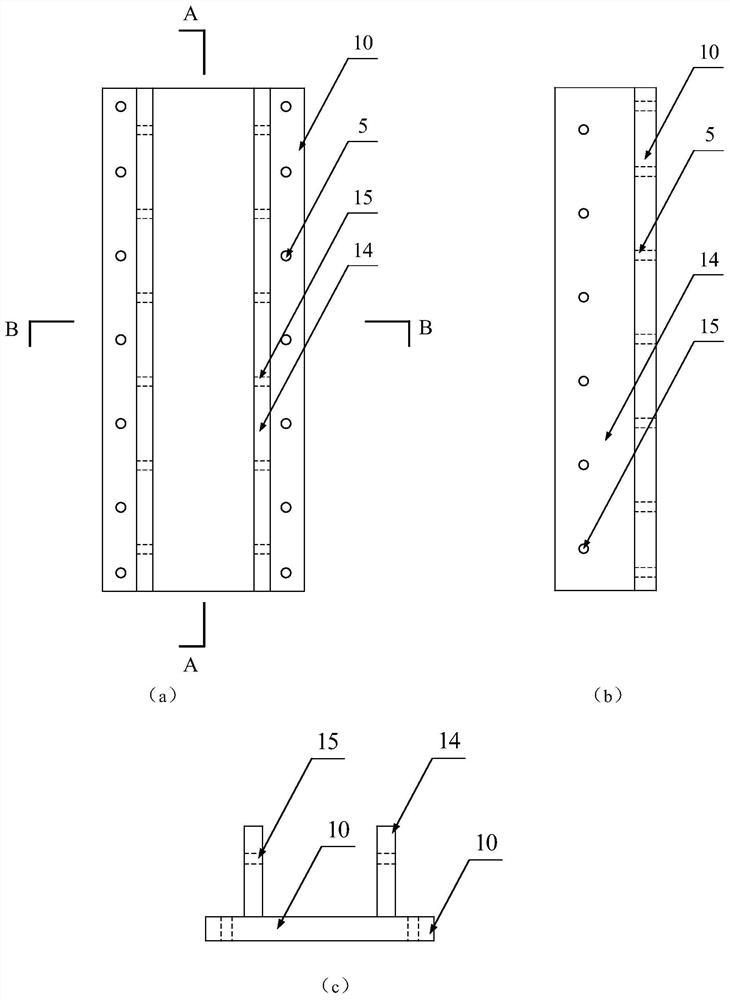

[0040] Among them, the reinforcement process of adding external prestressed steel wire rope 1 is adopted for the severely cracked area of the concrete on the surface of the tower column. The reinforcement process includes the following steps:

[0041] Step 1: According to the cracks on the surface of the concrete tower column and the radian of the tower column section, each layer of hoop prestressed steel wire rope 1 is divided into m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com