Tyre crane festoon cable layout tool and working principle

A cable laying and tire hanging technology, applied in cable laying equipment, overhead lines/cable equipment, etc., can solve the problems of not meeting the cable laying requirements of cable suppliers, difficult to meet technical requirements, pulling and breaking cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

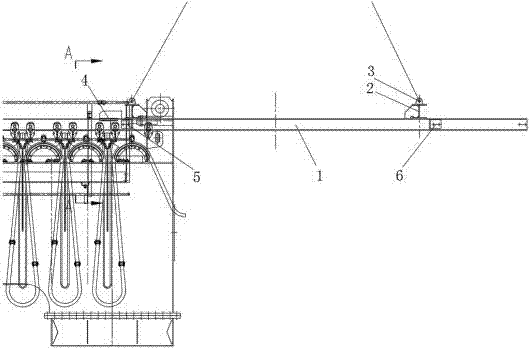

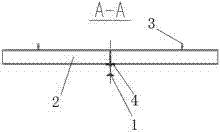

[0018] Such as Figure 1-2 The shown cable laying tool for tire cranes includes an I-shaped guide channel steel 1, two suspension beams 2 are fixed on the upper surface of the guide channel steel 1 and four suspension rings 3 are arranged, and the suspension beam 2 is integrally forward Offset, the front end of the guide channel steel 1 is fixedly provided with a guide block 4, and the front stopper 5 and the rear stopper 6 are also fixedly arranged on the guide channel steel 1 by bolts and nuts.

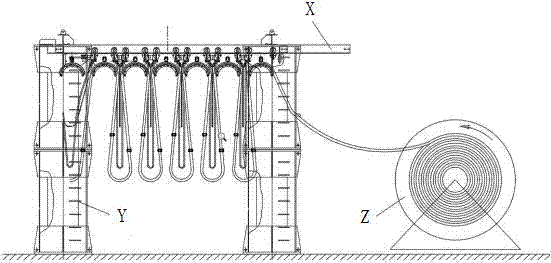

[0019] Such as image 3 As shown, the working principle of a tire crane towing cable laying tool, the specific steps are as follows:

[0020] The first step is to place the tooling for laying the cable of the tire crane on the ground cylinder frame, release the cable on the cable drum, and lay the released cable to the tooling on the tooling. After the laying is completed, tie the cable firmly And install the front stopper and rear stopper;

[0021] Step 2: Lift the tire crane to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com