Fluid Power Actuator For A Process Valve

A process fluid and actuator technology, which can be used in fluid pressure actuation devices, fluid pressure actuation system safety, fluid pressure converters, etc., and can solve problems such as contamination of hydraulic fluid and damage to actuator components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

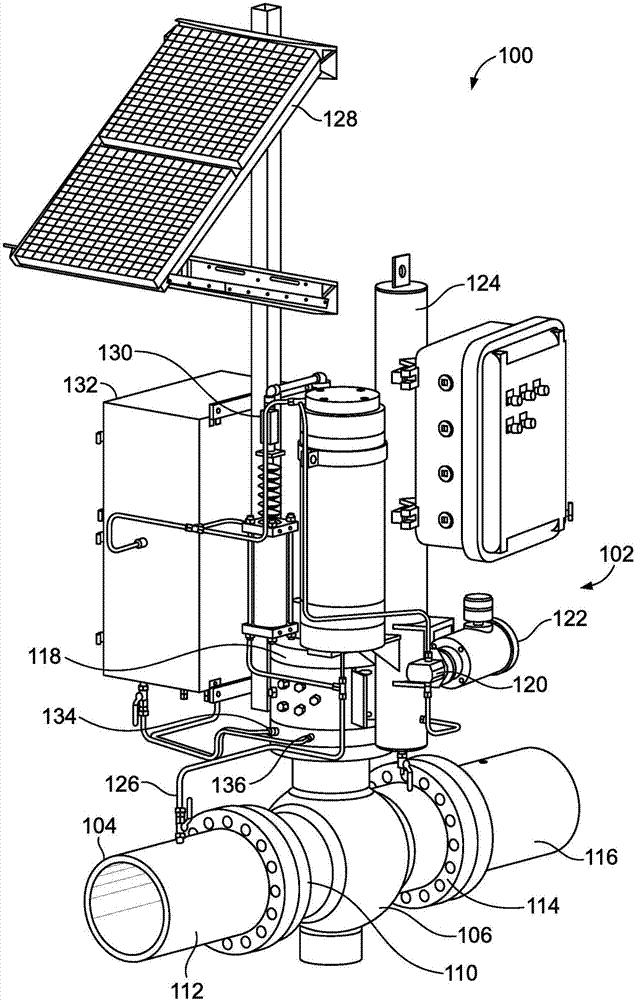

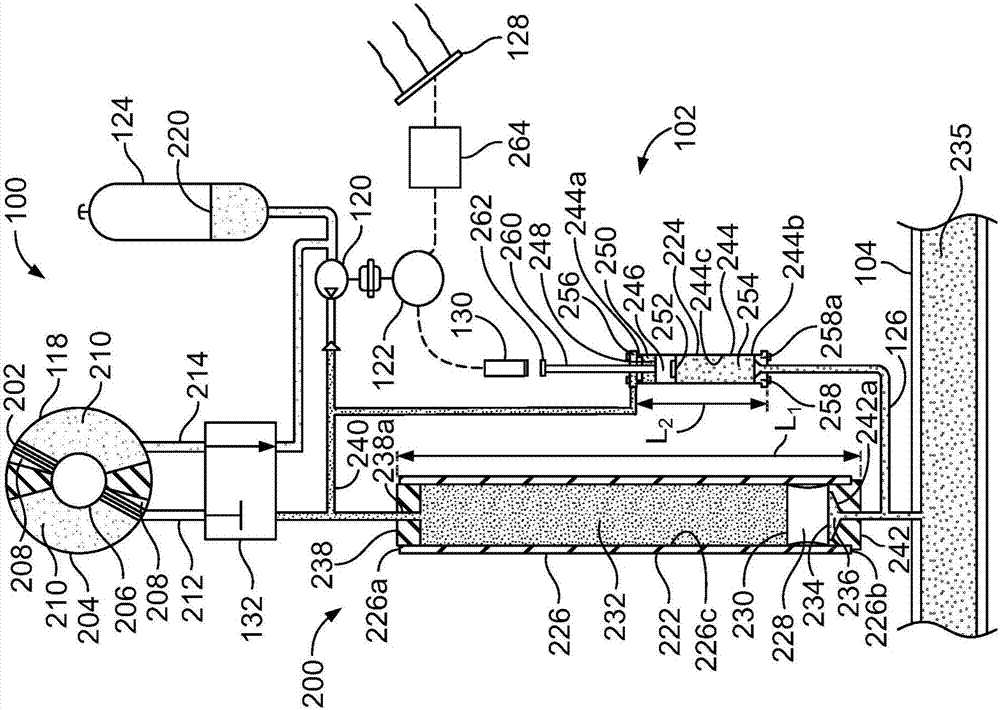

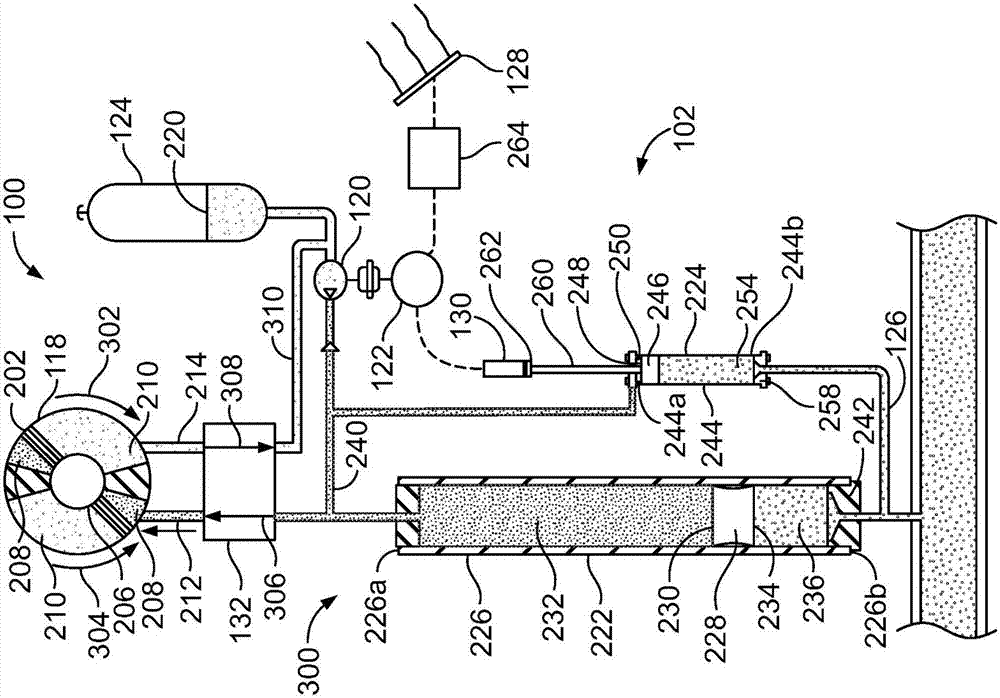

[0012] The control fluid power devices of the examples disclosed herein may be used in remote locations (eg, where pneumatic or electric power may not be available) to provide power (eg, hydraulic power) to process system components or equipment. For example, the control fluid power devices disclosed herein may be used to provide pressurized control fluid (e.g., hydraulic equipment) to devices such as cylinders, valve actuators, or other mechanisms that require high pressure fluid to operate (e.g., Hydraulic oil). Specifically, like oil and gas systems, example control fluid power devices disclosed herein use pressurized process fluid (eg, natural gas) to pressurize and / or deliver pressurized control fluid to process system components during operation. However, unlike conventional oil and gas systems, the example control fluid power devices disclosed herein do not vent process fluid to atmosphere. Instead, any process fluid used by the example control fluid power devices disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com