Incinerator

A technology for incinerators and furnace bodies, applied in the field of incinerators, can solve problems such as large environment, poor working environment, and insufficient combustion, and achieve the effects of improving incineration efficiency and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

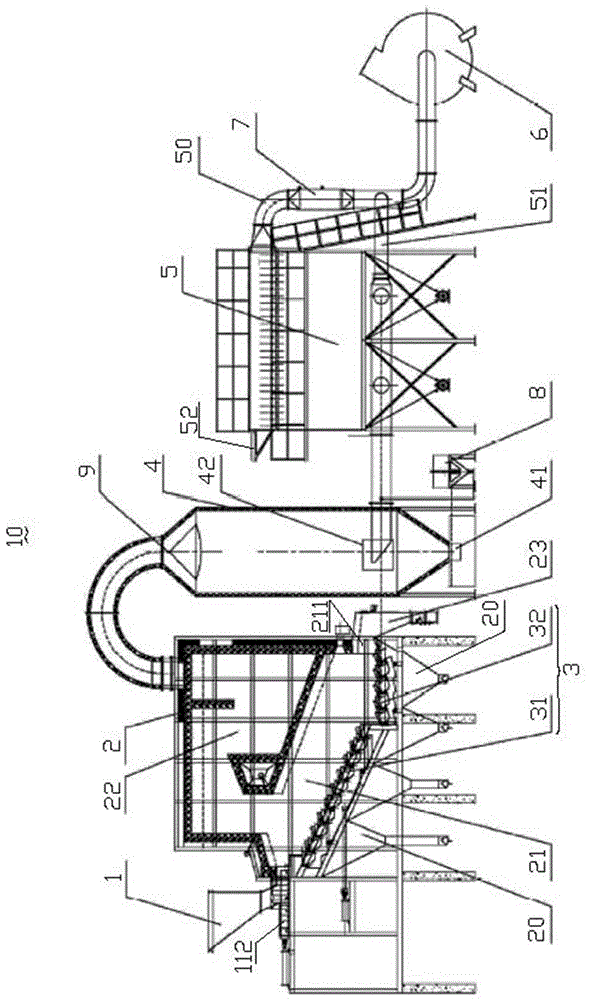

[0013] Such as figure 1 As shown, it is a schematic diagram of the side structure of the incinerator in a preferred embodiment of the present invention.

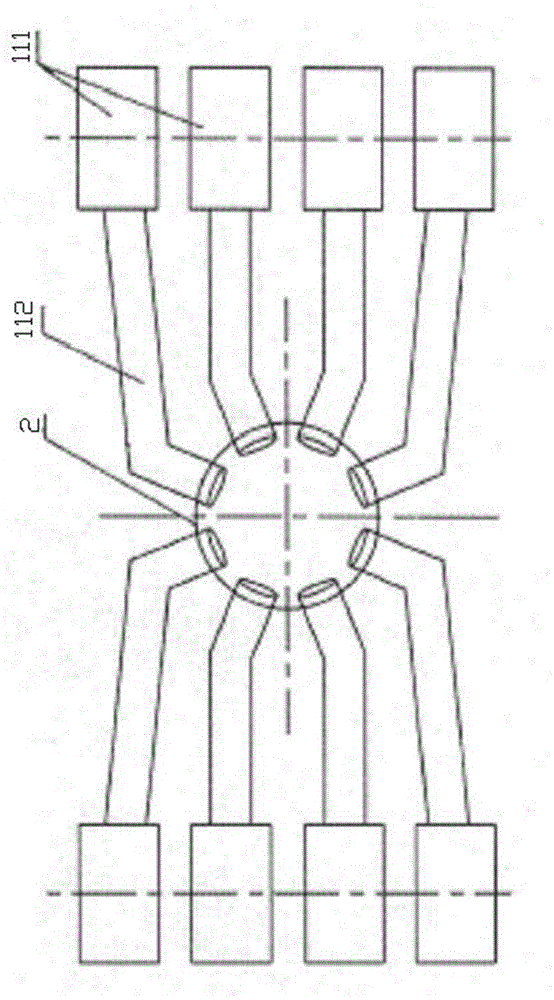

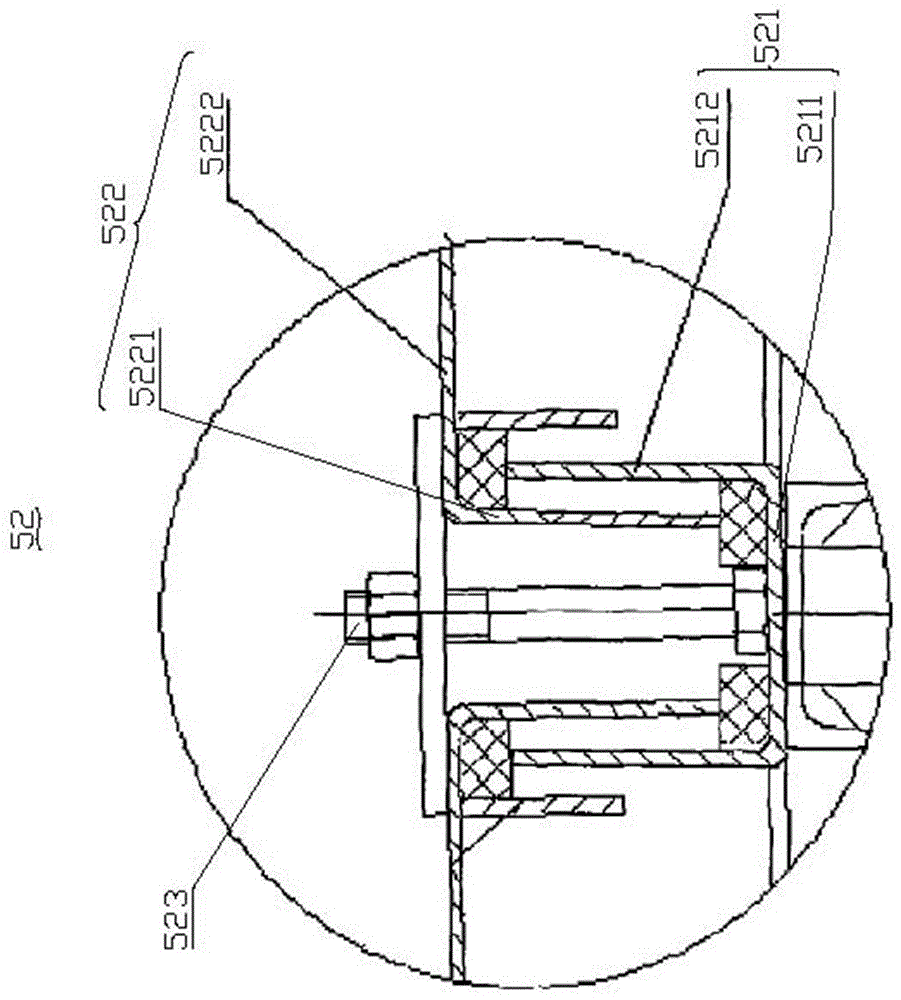

[0014] In this embodiment, the incinerator 10 is used to incinerate domestic waste. The incinerator includes a hopper 1, a furnace body 2, a reciprocating fire grate 3, a deacidification tower 4, a bag filter 5, and an induced draft fan 6 connected in sequence. Wherein, the furnace body 2 includes a plurality of air supply chambers 20 , a first combustion chamber 21 , a second combustion chamber 22 and an ash hopper 33 . The reciprocating fire grate 3 includes a first reciprocating fire grate 31 and a second reciprocating fire grate 32 . The deacidification tower 4 is also provided with an activated carbon spraying device 8 and an atomizing spraying device 9 corresponding to its outlet and inlet respectively. The bag filter 5 is also provided with a nanoreactor 7 . Wherein, the outlet of the deacidification tower 4 leads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com