Fully-automated flame adjuster

A fully automatic and fire-adjusting technology, applied in the field of machinery, can solve the problems of not being completely uniform in speed, not having a rejecting station in the detection equipment, and difficult to precisely control the station.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

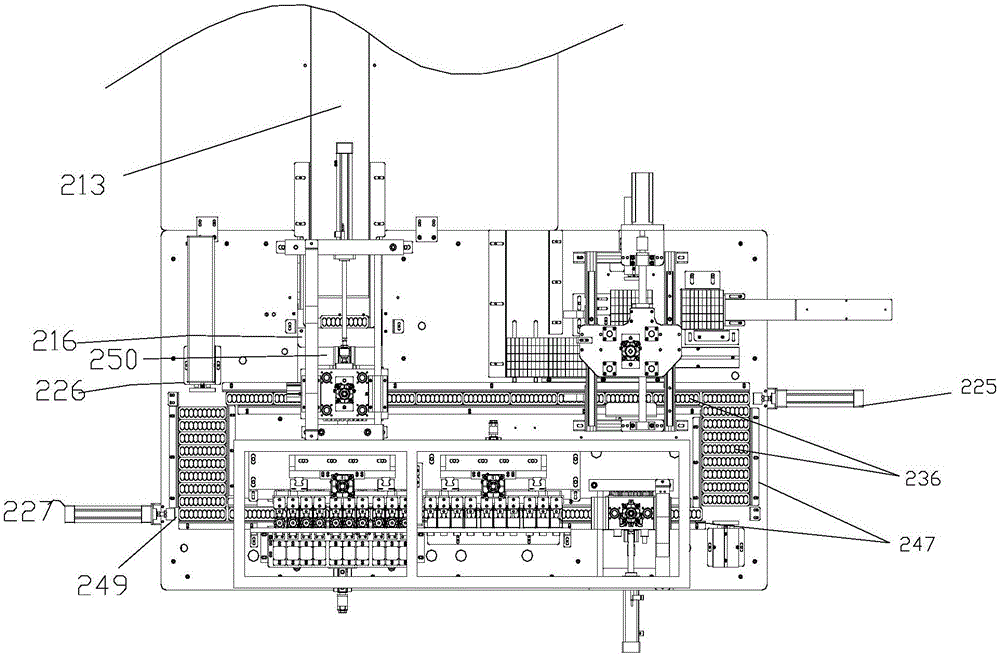

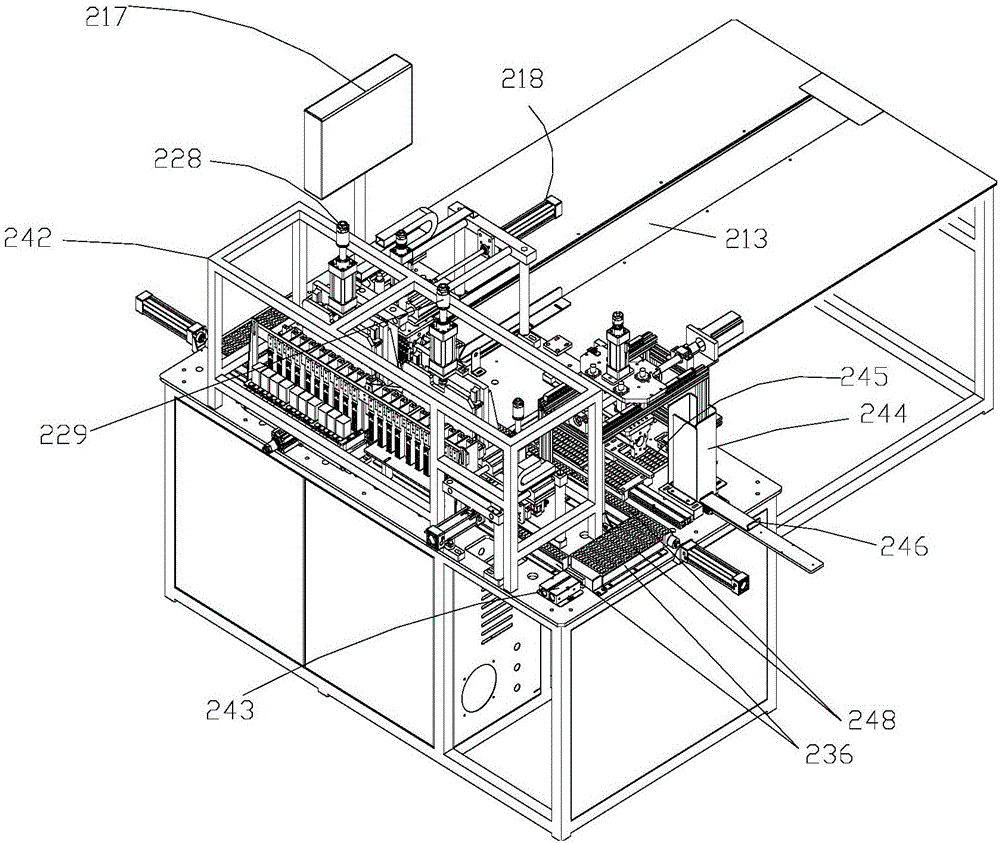

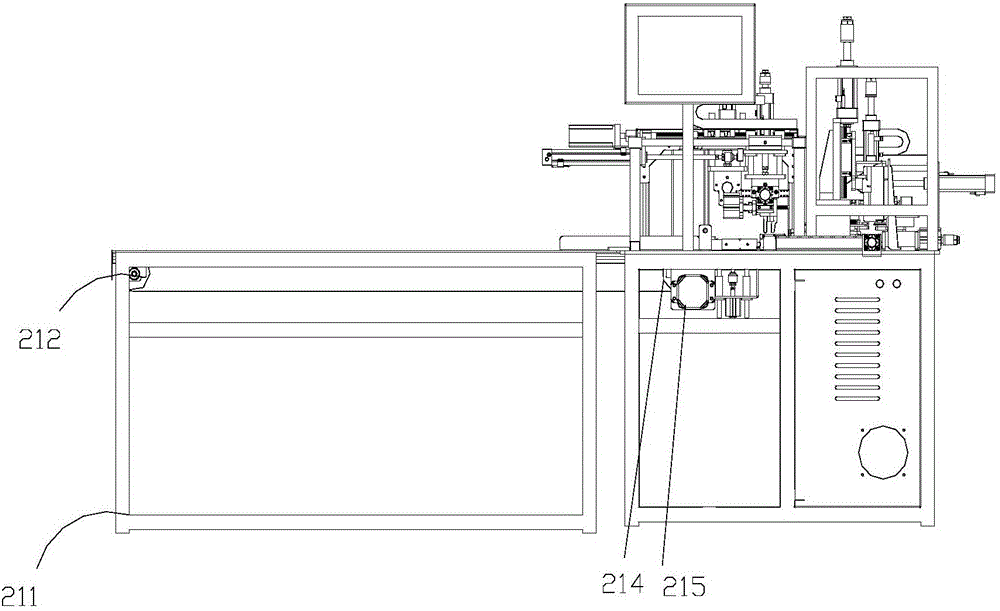

[0025] like Figure 1-2 The shown fully automatic lighter includes a material placement table 211, a rectangular rail 247 is installed on the material placement table 211, a material box 236 is placed inside the rectangular rail 247, and push-pull devices are respectively installed at the four corners of the rectangular rail 247 , along the material transmission direction, the push-pull device includes a first horizontal push-pull device, a first vertical push-pull device, a second horizontal push-pull device, and a second vertical push-pull device, and a gap 249 is provided on the rectangular track 247 corresponding to the push-pull device. A horizontal push-pull device, the first vertical push-pull device, the second horizontal push-pull device and the second vertical push-pull device cooperate to push so that the material box 236 moves along the rectangular track 247; The defective product rejecting mechanism is equipped with a feeding clamping mechanism in cooperation with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com