Central standard boards and elevation reference points setting method for production line of sintering machine

A center mark and reference point technology, which is applied in the field of center mark and elevation reference point setting of sintering machine production line, achieves the effect of strong operability, scientific and reasonable setting, and improved installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

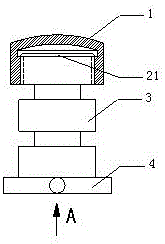

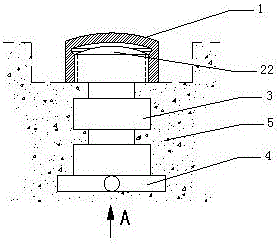

Image

Examples

Embodiment 1

[0036] The method for setting the center target plate and the elevation reference point of the sintering machine production line of the present invention, the sintering machine production line is 120m long, a head wheel is arranged at 6m at one end of the production line, and a tail wheel is arranged at 100m at the other end, including the following steps:

[0037] a. Basic acceptance

[0038] According to the equipment installation drawings, the foundation center line, elevation, pre-embedded bolts and reserved bolt holes shall be re-inspected for the transferred foundation, and records shall be made so as to be compared and verified with the civil engineering major; the foundation acceptance also includes: Check the reference line of civil engineering, use the total station or ordinary theodolite to check the reference line of civil engineering inspection, the allowable deviation is ±2mm.

[0039] b. Prepare the center target plate and the elevation reference point

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com