Working Vehicle

A technology for operating vehicles and suction boxes, which is applied in agriculture, agricultural machinery and implements, and air cooling. It can solve the problems of cooling efficiency decline, increase cleaning and other maintenance procedures, and increase wind speed, so as to avoid the decline of cooling efficiency and improve the cooling efficiency. Cooling efficiency, effect of increasing air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

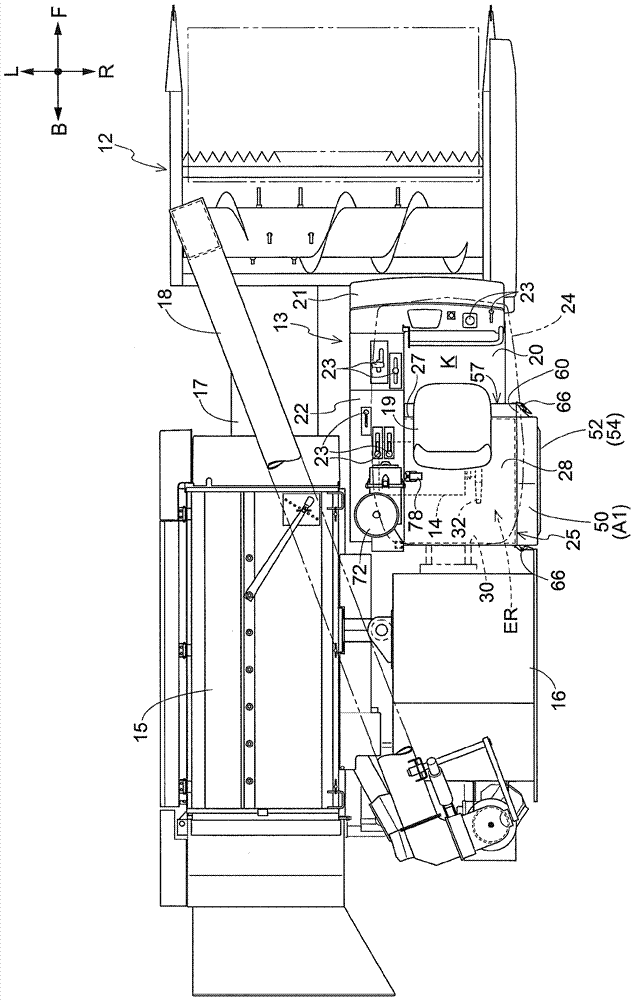

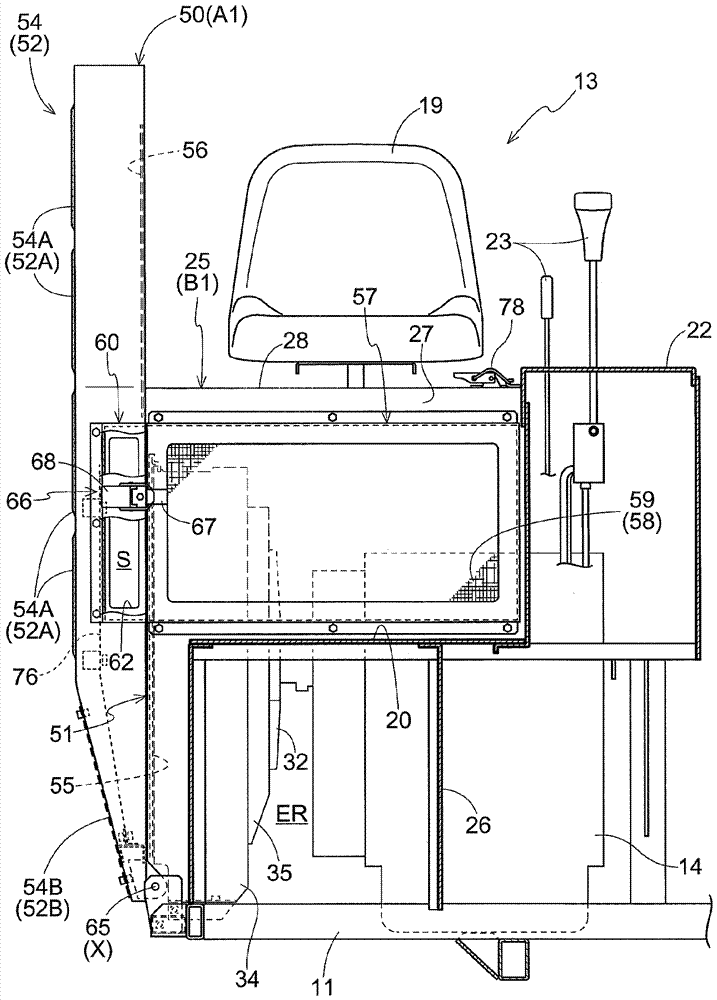

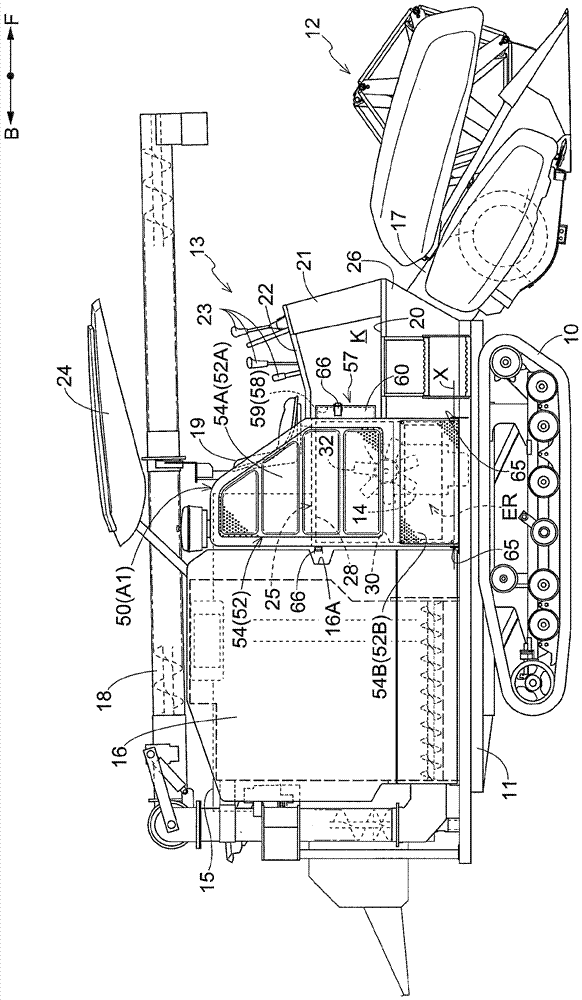

[0102] Hereinafter, an embodiment as an example of the present invention will be described with reference to the drawings.

[0103] In the following description, regarding the running body of an ordinary combine harvester (an example of a "work vehicle"), figure 1 and figure 2 The direction of the arrow F shown is "front of the body", and the direction of the arrow B is "rear of the body", figure 2 The direction of the indicated arrow L is "the left side of the machine body", and the direction of the arrow R is "the right side of the machine body".

[0104] Such as figure 1 and figure 2 As shown, the traveling body of the ordinary type combine has a left and right pair of crawler-type traveling devices 10 and a body frame 11 assembled into a frame shape supported by the traveling devices 10 . At the front end part of the body frame 11, the reaping|reaping part 12 which reaps the stalk of planting grain is provided so that it can ascend and descend. The driving part 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com