Universal type compressing tool

A general-purpose, tooling technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as applicability and practicality limitations, tooling accumulation on production sites, inconvenient management, etc., to achieve good practicability and good use stability. , Reasonable effect of structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

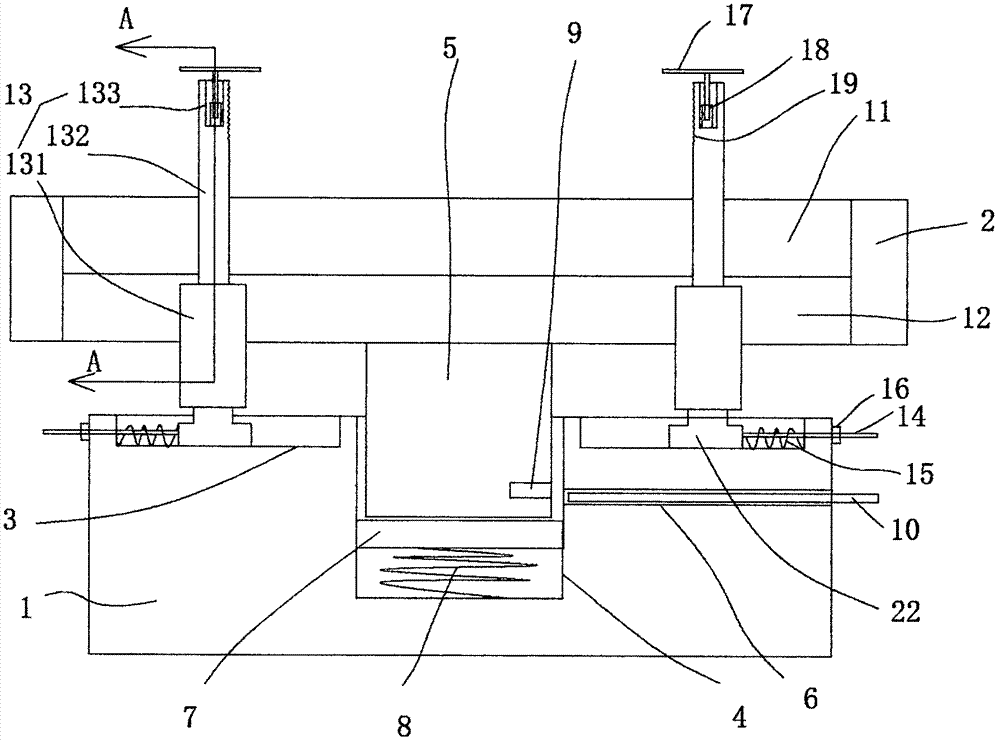

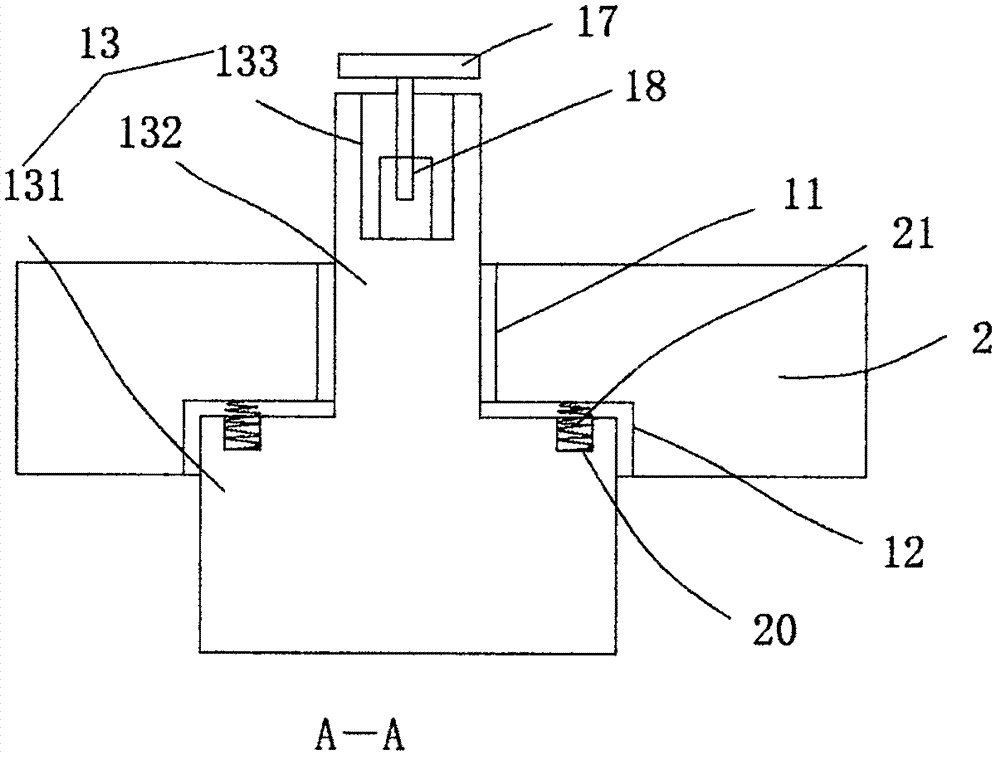

[0015] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 Middle A-A partial cross-sectional view.

[0016] See figure 1 and figure 2 , a general-purpose pressing tool, including a base 1 and a pressing platform 2 arranged on the base 1, an adjustment slot 3 with an opening on the top surface is provided in the base 1, and in the base 1 A concave cavity 4 with an opening on the top surface is provided, and a post 5 is integrally formed in the center of the bottom surface of the pressing platform 2, and a positioning hole 6 communicating with the concave cavity 4 is provided on the side of the base 1, A butt plate 7 is arranged in the concave cavity, a spring 8 is fixed between the bottom wall of the concave cavity and the abutment plate, the positioning hole is above the butt plate, and a spring 8 is fixed on the pole 5. There is a positioning soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com