Composite board

A composite board and composite layer technology, applied in the field of composite boards, can solve the problems of poor gluing stability, separation of the first composite layer and the second composite layer, and unsatisfactory gluing strength, so as to improve the gluing stability, improve the gluing strength, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

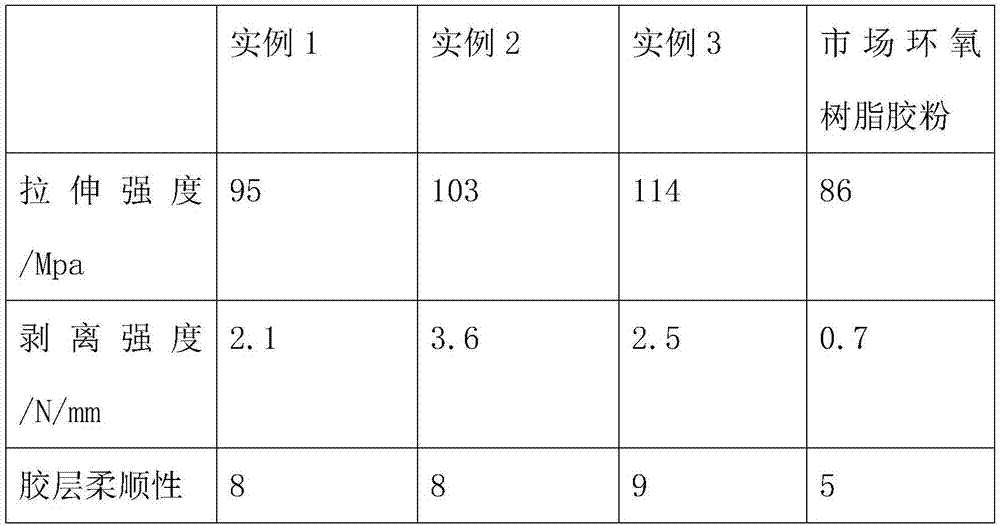

Embodiment 1

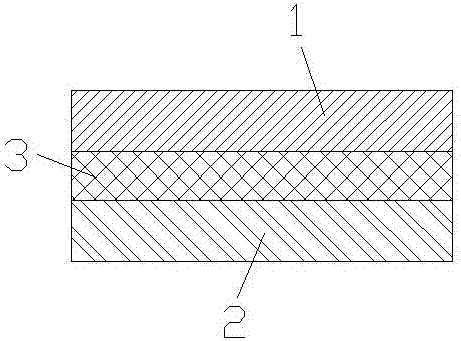

[0023] Such as figure 1 A composite board is shown, comprising a first composite layer 1 and a second composite layer 2, the first composite layer 1 is bonded to the second composite layer 2 through an adhesive layer 3; the adhesive layer 3 is made of a single The component epoxy resin powder is heated and melted.

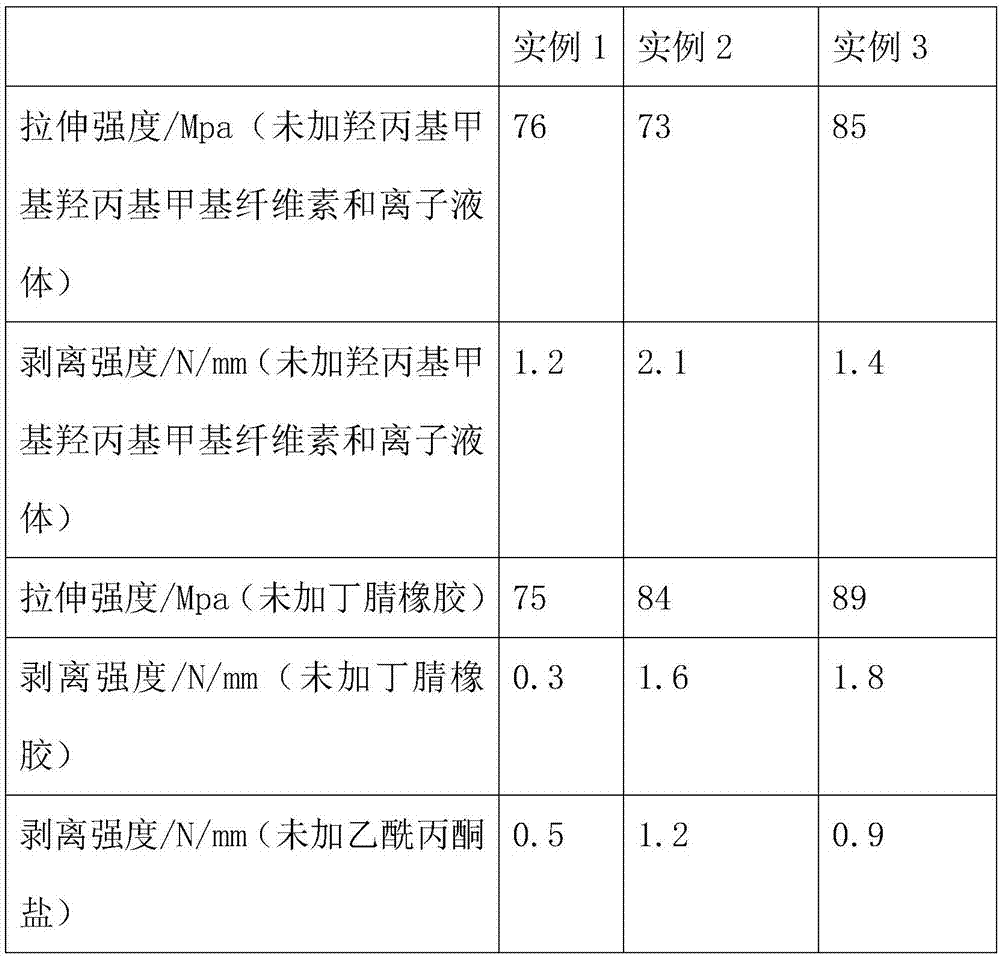

[0024] The one-component epoxy resin powder includes epoxy resin powder, hydroxypropyl methylcellulose / ionic liquid, allyl succinimidyl carbonate, 2,3,5-trimethylpyrazine, Methyl Bromide Triphenylphosphine Salt, N,N-Bis(Hydroxyethyl) Cocamide, Liquid Nitrile Rubber, Acetylacetonate Salt, Limestone Powder.

[0025] The parts by weight of each component in the rubber powder are: 80 parts of epoxy resin powder, 0.009 part of hydroxypropyl methylcellulose, 0.091 part of 1-ethyl-3-methylimidazolium bromide ionic liquid, and 0.091 part of liquid butyl 0.1 part of nitrile rubber, 0.1 part of aluminum acetylacetonate, 0.1 part of limestone powder, 1 part of allyl succini...

Embodiment 2

[0036] Such as figure 1 A composite board is shown, comprising a first composite layer 1 and a second composite layer 2, the first composite layer 1 is bonded to the second composite layer 2 through an adhesive layer 3; the adhesive layer 3 is made of a single The component epoxy resin powder is heated and melted.

[0037] The parts by weight of each component in the rubber powder are: 100 parts of epoxy resin raw powder, 0.454 parts of hydroxypropyl methylcellulose, 4.54 parts of 1-butyl-3 methylimidazole chloride ionic liquid, liquid butyronitrile 10 parts of rubber, 3 parts of magnesium acetylacetonate, 1 part of limestone powder, 3 parts of allyl succinimidyl carbonate, 1.5 parts of 2,3,5-trimethylpyrazine, 0.75 parts of methyl bromide triphenylphosphine , 0.5 parts of N,N-di(hydroxyethyl)cocamide;

[0038] The liquid nitrile rubber is liquid nitrile rubber-34. The molecular weight of liquid nitrile rubber-34 is 3800-4500, the viscosity is 450pa.s when the temperature i...

Embodiment 3

[0048] Such as figure 1 A composite board is shown, comprising a first composite layer 1 and a second composite layer 2, the first composite layer 1 is bonded to the second composite layer 2 through an adhesive layer 3; the adhesive layer 3 is made of a single The component epoxy resin powder is heated and melted.

[0049] The parts by weight of each component in the rubber powder are: 120 parts of epoxy resin raw powder, 0.91 parts of hydroxypropyl methylcellulose, 9.01 parts of 2-ethyl-4-methylimidazolium bromide ionic liquid, and 9.01 parts of liquid butyl 20 parts of nitrile rubber, 6 parts of cobalt acetylacetonate, 2 parts of limestone powder, 5 parts of allyl succinimidyl carbonate, 2 parts of 2,3,5-trimethylpyrazine, 1 part of methyl bromide triphenylphosphine 0.7 parts, N, N-two (hydroxyethyl) cocamides;

[0050] The liquid nitrile rubber is liquid nitrile rubber-40. Liquid nitrile rubber-40 has a molecular weight of 6000-8000, a viscosity of 850 pa.s when the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap