Base used for rotary compressor, rotary compressor and refrigerating equipment

A rotary compressor and rotary compressor technology, applied in the field of compressors, can solve the problems of difficulty in noise and vibration, low vibration absorption capacity, and large external influence, and achieve the effects of reducing vibration and resonance, good quality, and improved sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

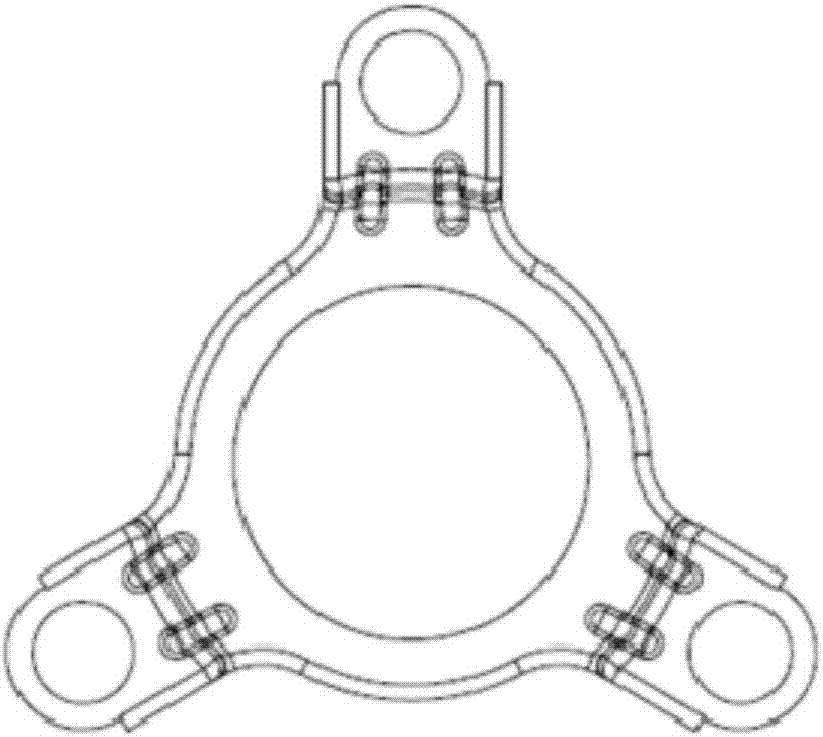

Image

Examples

Embodiment 1

[0035] The base for the rotary compressor is formed of a magnesium alloy containing 0.2% by weight of copper, 1.0% by weight of manganese, 0.25% by weight of zinc, 0.16% by weight of silicon, 0.1% by weight of titanium and the balance of magnesium.

[0036]The above-mentioned base for the rotary compressor was used for the rotary compressor, and the tensile strength and damping performance SDC of the base for the rotary compressor were tested. The test results are shown in Table 1.

Embodiment 2

[0038] A base for a rotary compressor is formed of a magnesium alloy containing 9.0% by weight of aluminum, 0.3% by weight of manganese, 0.9% by weight of zinc, 0.3% by weight of silicon, 0.2% by weight of copper, 0.05% by weight of iron, and amount of magnesium.

[0039] The above-mentioned base for the rotary compressor was used for the rotary compressor, and the tensile strength and damping performance SDC of the base for the rotary compressor were tested. The test results are shown in Table 1.

Embodiment 3

[0041] The base for the rotary compressor is formed of a magnesium alloy containing 3.7% by weight of zinc, 0.1% by weight of copper, 1.0% by weight of zirconium, 0.8% by weight of yttrium, and the balance of magnesium.

[0042] The above-mentioned base for the rotary compressor was used for the rotary compressor, and the tensile strength and damping performance SDC of the base for the rotary compressor were tested. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap