Angle throttle valve with valve rod directly screwed into valve rod nut for controlling ascending and descending of open-close piece

A technology of valve stem nuts and opening and closing parts, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of high cost, many materials, and large volume of throttle valves, and achieve light weight, increased efficiency, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

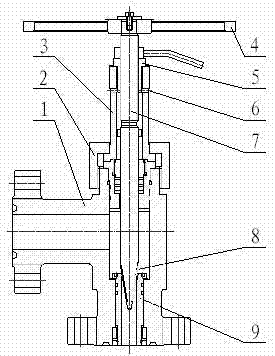

[0008] As shown in the accompanying drawings, the bracket 3 is a tubular body with a flange edge at the bottom, and an internal thread is provided at the upper end; an external thread is provided on the outer side of the upper part of the valve cavity hole in the valve body 1; the tight cap 2 is an upper through hole, and the lower part The blind hole and the lower end of the blind hole are provided with a cylindrical body with internal threads; the through hole on the tight cap 2 passes through the bracket 3 and is screwed to the external thread on the upper part of the valve body 1 through the internal thread at the lower end of the blind hole, and at the same time tightens The lower end plane at the through hole of the cap 2 presses the upper end plane of the lower flange side of the bracket 3 to form a whole between the bracket 3 and the valve body 1; the valve stem nut 5 is a tubular body with internal and external threads and a flange side on the upper part. body; the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com